Manufacturing method of formaldehyde, glycolaldehyde and glycol

A manufacturing method and glycolaldehyde technology, which are applied in chemical instruments and methods, preparation of organic compounds, preparation of carbon-based compounds, etc., can solve problems such as complex manufacturing steps and multiple steps, and achieve simplified manufacturing steps, reduced manufacturing costs, The effect of reducing manufacturing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

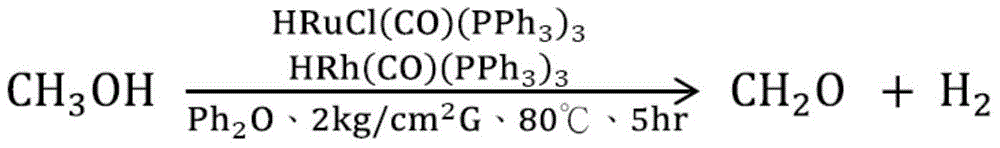

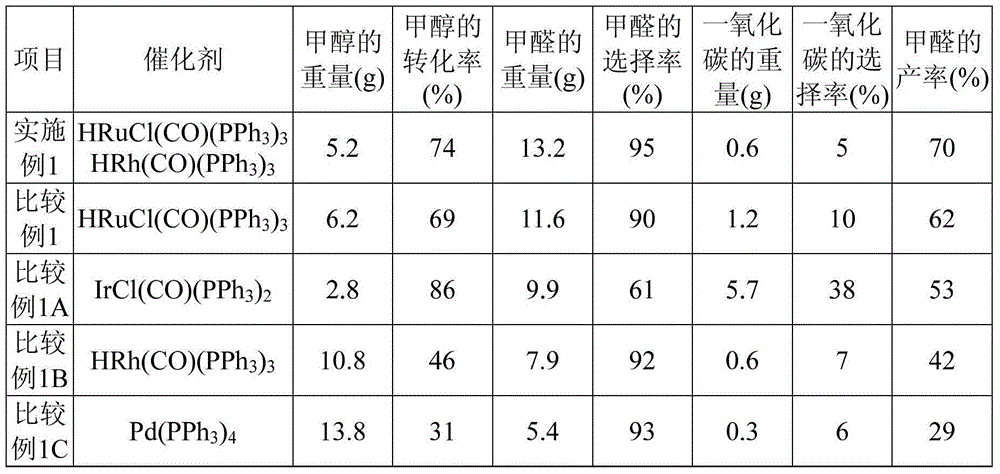

[0025] The present embodiment provides a kind of formaldehyde manufacture method, comprises in autoclave, the methyl alcohol of charging 20g, in diphenyl ether (Ph 2 In the presence of O) at a temperature of 80°C and a pressure of 2kg / cm 2 Under the condition of G, catalyze with rhodium (Rh) catalyst and ruthenium catalyst (Ru) as catalyst composition, make methanol react about 5 hours, and make formaldehyde, and simultaneously obtain hydrogen (H 2 ) and carbon monoxide (CO). In this embodiment, the ruthenium catalyst can use for example 0.02g of HRuCl (CO) (PPh 3 ) 3 , while the rhodium catalyst can use for example 0.02g of HRh(CO)(PPh 3 ) 3 . The reaction formula of the above-mentioned formaldehyde production method is shown below.

[0026] Full response:

[0027]

[0028] side effects:

[0029] CH 2 O→CO+H 2

[0030] After the reaction was completed, the content of the autoclave was measured, and the conversion rate of the reactant, the yield rate of the product...

Embodiment 2

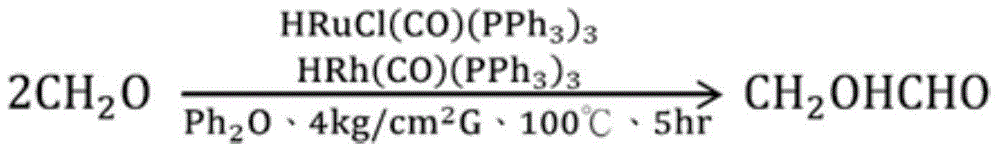

[0040] This embodiment provides a method for producing glycolaldehyde, comprising charging 20 g of formaldehyde, preferably anhydrous formaldehyde, into a high-pressure reactor. In diphenyl ether (Ph 2 In the presence of O) at a temperature of 100°C and a pressure of 4kg / cm 2 Under the condition of G, the rhodium catalyst and the ruthenium catalyst are used as the catalyst composition for catalysis, and the formaldehyde (anhydrous) is reacted for about 5 hours to produce glycolaldehyde and carbon monoxide at the same time. In this embodiment, the ruthenium catalyst can use for example 0.02g of HRuCl (CO) (PPh 3 ) 3 , while the rhodium catalyst can use for example 0.02g of HRh(CO)(PPh 3 ) 3 . The reaction formula of the above-mentioned method for producing glycolaldehyde is shown below.

[0041] Full response:

[0042]

[0043] After the reaction was completed, the content of the autoclave was measured, and the conversion rate of the reactant, the yield rate of the pr...

Embodiment 3

[0051] This embodiment provides a method for producing ethylene glycol, comprising charging 20 g of glycolaldehyde and an appropriate amount of hydrogen into a high-pressure reactor. In diphenyl ether (Ph 2 In the presence of O) at a temperature of 120°C and a pressure of 20kg / cm 2 Under the condition of G, the rhodium (Rh) catalyst and the ruthenium catalyst (Ru) are used as the catalyst composition for catalysis, and the glycolaldehyde is hydrogenated for about 5 hours to obtain ethylene glycol. In this embodiment, the ruthenium catalyst can use for example 0.02g of HRuCl (CO) (PPh 3 ) 3 , while the rhodium catalyst can use for example 0.02g of HRh(CO)(PPh 3 ) 3 . The reaction formula of the method for preparing ethylene glycol by hydrogenating glycolaldehyde is as follows.

[0052] Full response:

[0053]

[0054] After the reaction was completed, the content of the autoclave was measured, and the conversion rate of the reactant, the yield rate of the product, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com