Polymerization tank

A technology of polymerization box and sample chamber, applied in the field of polymerization box and biological sample preparation, can solve the problems of difficult to guarantee the cooling speed, unstable sample quality, uncontrollable temperature, etc. fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

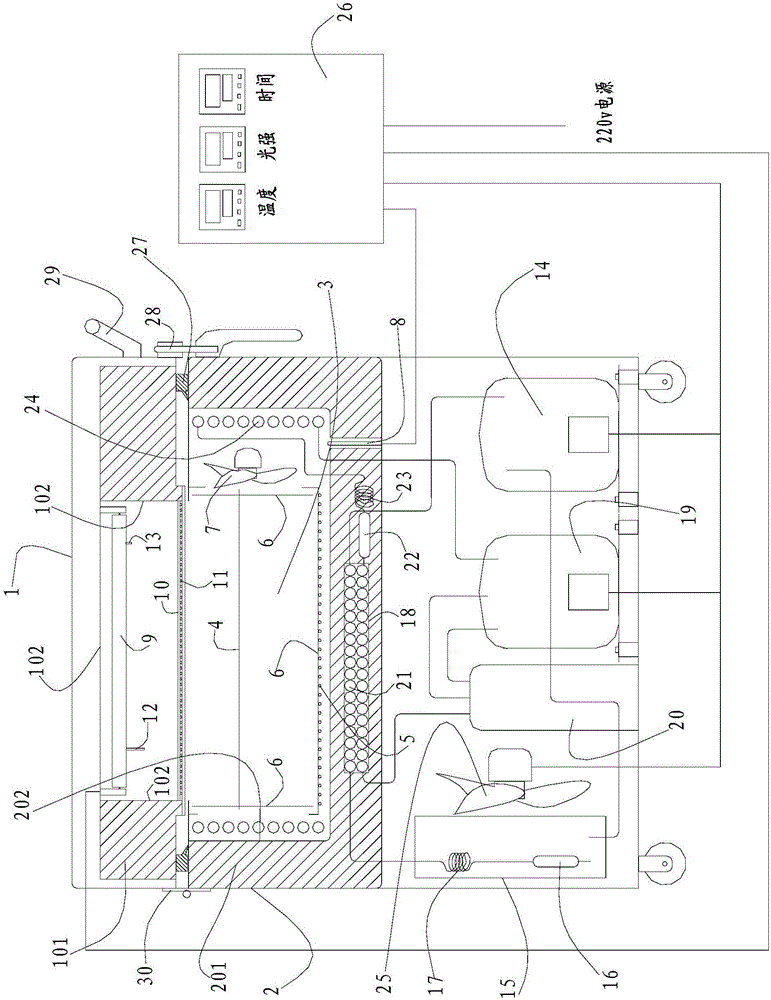

[0025] Such as figure 1 As shown, the polymerization box includes an insulation case body 2 provided with a sample chamber 3 and an insulation cover body 1 covered above the insulation case body 2, and a sample rack 4 is arranged in the sample chamber 3 of the insulation case body 2, An ultraviolet lamp chamber corresponding to the sample holder 4 is embedded in the heat preservation cover 1 , and a refrigeration system is provided in the heat preservation shell body 2 , and the refrigeration evaporator 24 in the refrigeration system is arranged on the side wall of the sample chamber 3 .

[0026] Owing to be provided with refrigeration system in insulation shell body 2, the refrigeration evaporator 24 of this refrigeration system is arranged on the sidewall of sample chamber 3, thereby adjust the refrigeration temperature of refrigeration system and can set the indoor temperature of sample chamber 3, make polymerization box The temperature of the inner sample chamber 3 is prec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com