Lightweight conductive shielding composite material and preparation method thereof

A technology of conductive shielding and composite materials, which is applied in the field of lightweight conductive shielding composite materials and its preparation, can solve the problems of affecting the electromagnetic shielding performance of the product, easily polluting the environment, and degrading the mechanical properties of the product, so as to be suitable for large-scale The effect of industrialized production, reliable electromagnetic shielding performance and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] The specific steps of preparation are:

[0039] Step 1. First, mix the fluoroplastics, etched phases, carbon nanotubes and hollow glass beads at a weight ratio of 20:60:0.5:40 at 15°C to obtain a mixture; where the fluoroplastic is poly Vinyl fluoride, the etching phase is polyvinyl chloride, and the carbon nanotubes are multi-walled carbon nanotubes. Then put the mixture in a torque rheometer, and knead at 150°C and 100r / min for 20 minutes to obtain a mixture.

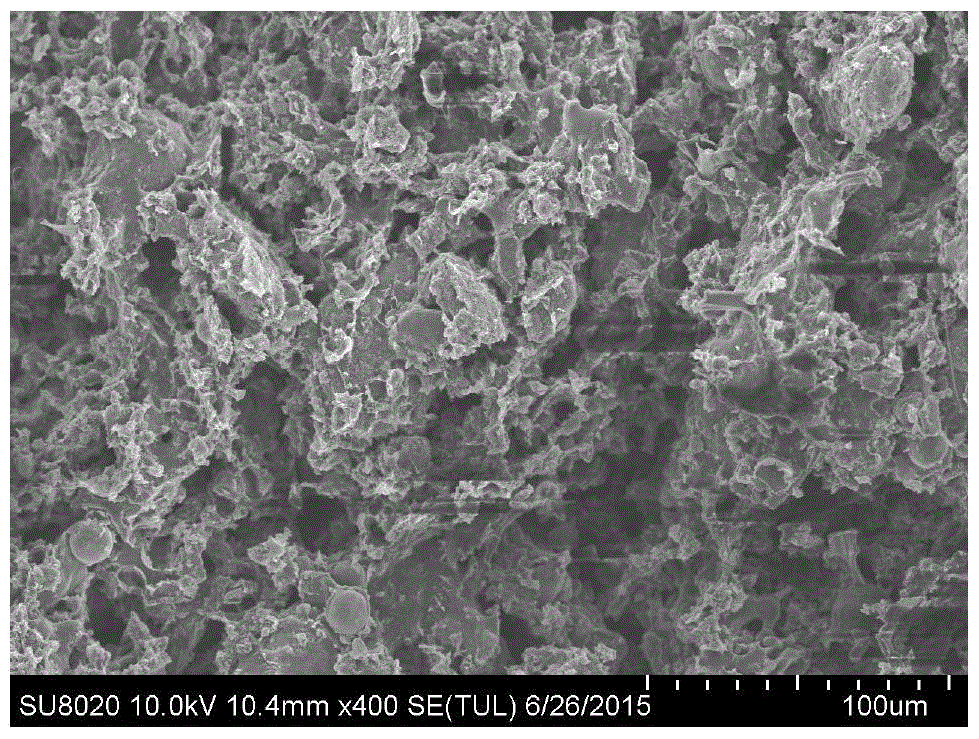

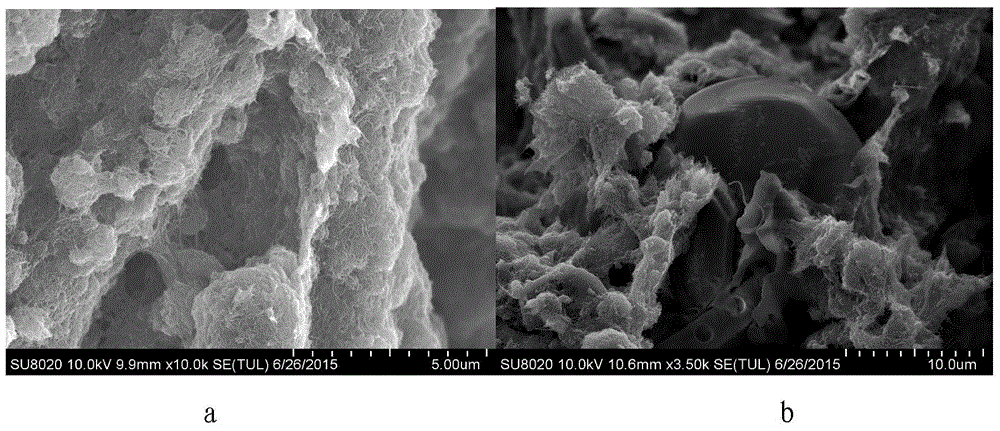

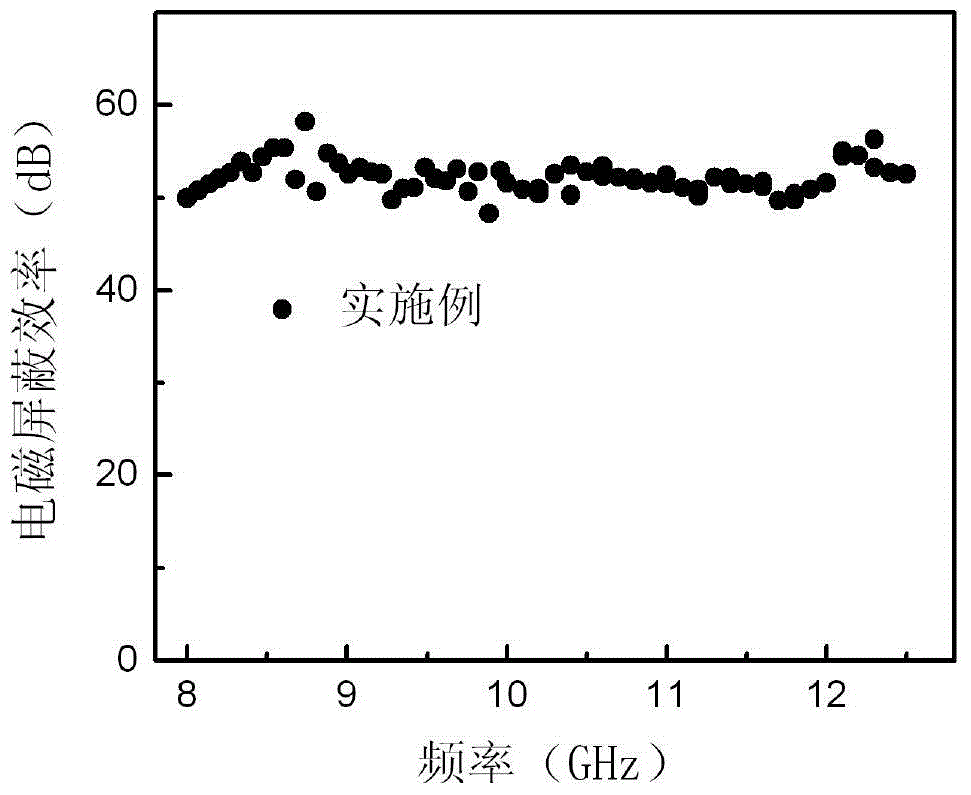

[0040] Step 2: Put the mixed material on a plate vulcanizing machine, and heat-press at 200°C and 10MPa for 60 minutes to obtain a composite board. The composite board was soaked in a solvent for 2 hours and then dried at 60°C for 15 hours. The solvent was xylene. Before drying the solvent-soaked composite board, ethanol was used to rinse the surface deposits. The system is similar to figure 1 with figure 2 As shown, and as image 3 Lightweight conductive shielding composite material shown in the curve.

Embodiment 2

[0042] The specific steps of preparation are:

[0043] Step 1. Firstly mix the fluoroplastic, etched phase, carbon nanotubes and hollow glass beads at a weight ratio of 30:50:5:30 at 19°C to obtain a mixture; where the fluoroplastic is polypolarized Vinyl fluoride, the etching phase is polyvinyl chloride, and the carbon nanotubes are multi-walled carbon nanotubes. Then put the mixture in a torque rheometer, and knead at 175°C and 83r / min for 17 minutes to obtain a mixture.

[0044] Step 2: Put the mixed material on a plate vulcanizing machine, and heat-press at 220°C and 8MPa for 48 minutes to obtain a composite board. The composite board was soaked in a solvent for 6 hours and then dried at 65°C for 18 hours; the solvent was xylene. Before drying the composite board soaked in the solvent, ethanol was used to rinse the surface deposits. The system is similar to figure 1 with figure 2 As shown, and as image 3 Lightweight conductive shielding composite material shown in the curv...

Embodiment 3

[0046] The specific steps of preparation are:

[0047] Step 1. Firstly mix the fluoroplastics, etched phases, carbon nanotubes and hollow glass beads at a weight ratio of 40:40:10:20 at 23°C to obtain a mixture; where the fluoroplastic is poly Vinyl fluoride, the etching phase is polyvinyl chloride, and the carbon nanotubes are multi-walled carbon nanotubes. Then put the mixture in a torque rheometer and knead at 200°C and 75r / min for 13 minutes to obtain a mixture.

[0048] Step 2: Put the mixed material on a plate vulcanizing machine, and hot press at 240°C and 5MPa for 35 minutes to obtain a composite board. The composite board was soaked in a solvent for 11 hours and then dried at 70°C for 10 hours; the solvent was xylene. Before drying the composite board soaked in the solvent, ethanol was used to rinse the surface deposits. Made like figure 1 with figure 2 As shown, and as image 3 Lightweight conductive shielding composite material shown in the curve.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com