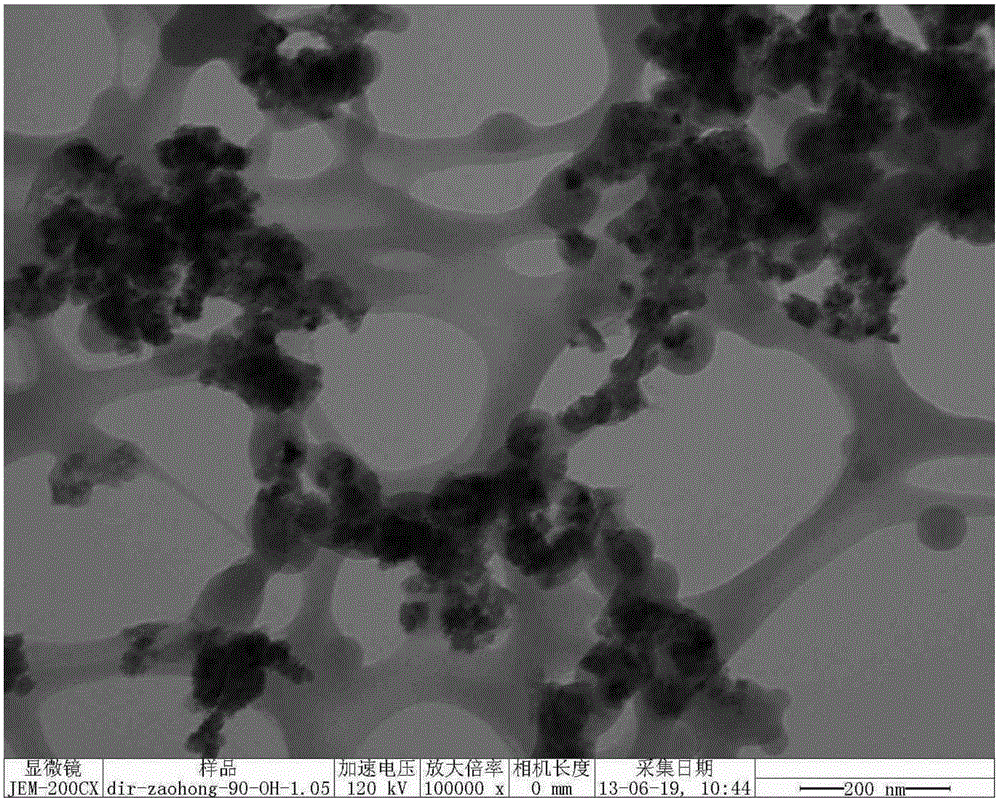

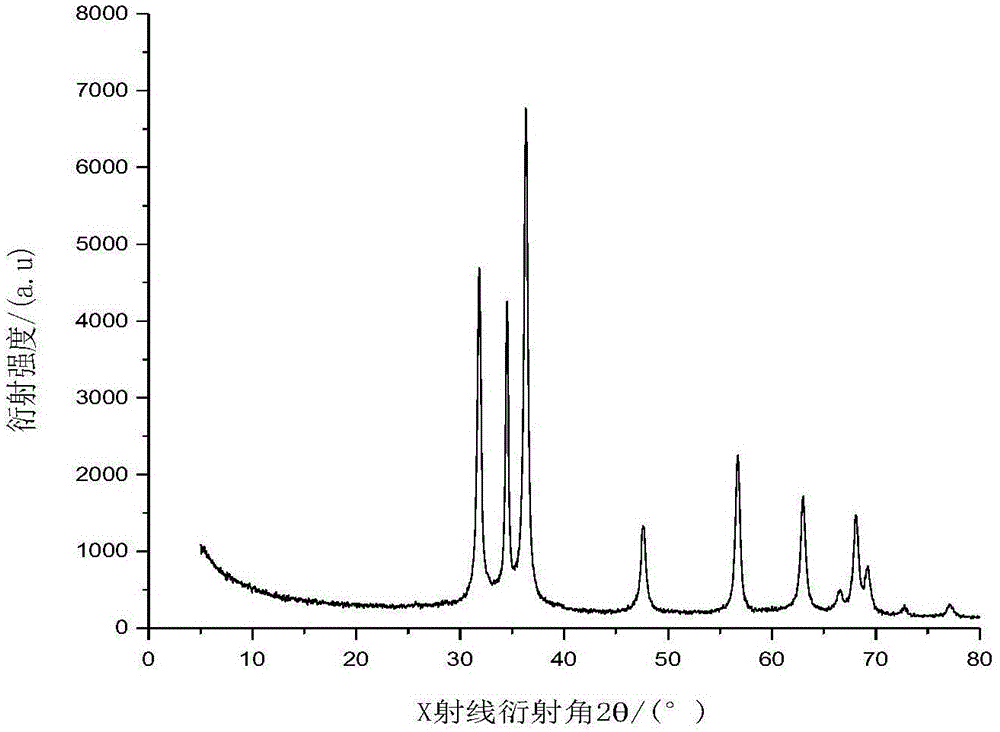

Preparation method of direct fast bordeaux/ZnO core-shell structured nanocomposite material

A nano-composite material and core-shell structure technology, which is applied in the field of preparation of direct acid-resistant jujube red/ZnO core-shell structure nano-composite materials, can solve the problems of polluting the environment and the release of toxicity of direct acid-resistant jujube red dye, and achieves the effect of solving environmental protection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Step 1: Weigh n-amyl alcohol, add sodium lauryl sulfate to it, stir to make it evenly mixed to form a mixed solution, and the mass ratio of sodium dodecyl sulfate and n-amyl alcohol in the obtained mixed solution is 2:3.1; Weigh the mixed solution and xylene at a mass ratio of 2:1, add xylene to the mixed solution to obtain a pseudo-binary component system;

[0024] Step 2: Weigh the direct acid-resistant date red dye and water according to the mass ratio of 1:8.1, and mix them uniformly to obtain the direct acid-resistant date red dye aqueous solution;

[0025] Step 3: according to the mass ratio of 6:1, get the quasi-binary component system obtained in step 1 and the direct acid-resistant date red dye aqueous solution prepared in step 2, after mixing evenly, get microemulsion A; according to the mass ratio of 11:1, take the step 1. Gained quasi-binary component system and concentration are the zinc nitrate solution of 0.4mol / L, after mixing uniformly, microemulsion B ...

Embodiment 2

[0029] Step 1: Weigh n-amyl alcohol, add sodium lauryl sulfate to it, stir to make it evenly mixed to form a mixed solution, and the mass ratio of sodium lauryl sulfate and n-amyl alcohol in the obtained mixed solution is 2:4; Weigh the mixed solution and xylene at a mass ratio of 1:1, add xylene to the mixed solution to obtain a pseudo binary component system;

[0030] Step 2: Weigh the direct acid-resistant date red dye and water according to the mass ratio of 1:9, and after mixing evenly, obtain the direct acid-resistant date red dye aqueous solution;

[0031] Step 3: according to the mass ratio of 6:1, get the quasi-binary component system obtained in step 1 and the direct acid-resistant date red dye aqueous solution prepared in step 2, after mixing evenly, get microemulsion A; according to the mass ratio of 12:1, take the step 1. Gained quasi-binary component system and concentration are the zinc nitrate solution of 0.2mol / L, after mixing uniformly, microemulsion B is obt...

Embodiment 3

[0035] Step 1: Weigh n-amyl alcohol, add sodium lauryl sulfate to it, stir to make it evenly mixed to form a mixed solution, and the mass ratio of sodium lauryl sulfate and n-amyl alcohol in the obtained mixed solution is 2:3.5; Weigh the mixed solution and xylene at a mass ratio of 1.5:1, add xylene to the mixed solution to obtain a pseudo binary component system;

[0036] Step 2: Weigh the direct acid-resistant date red dye and water according to the mass ratio of 1:8.2, and mix them uniformly to obtain the direct acid-resistant date red dye aqueous solution;

[0037] Step 3: according to the mass ratio of 7:1, get the quasi-binary component system obtained in step 1 and the direct acid-resistant date red dye aqueous solution prepared in step 2, after mixing evenly, get microemulsion A; according to the mass ratio of 11.2:1, take the step 1. Gained pseudo-binary component system and concentration are the zinc nitrate solution of 0.3mol / L, after mixing uniformly, microemulsio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com