Magnetron sputtering apparatus

A magnetron sputtering and equipment technology, applied in the field of magnetron sputtering technology, can solve the problems of low sputtering efficiency, uncontrollable deposition particles and deposition rate, etc., and achieve the effect of increasing the number of collisions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

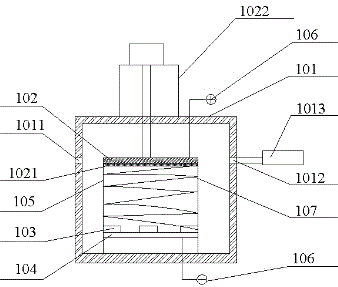

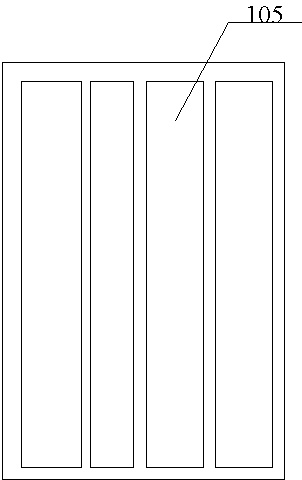

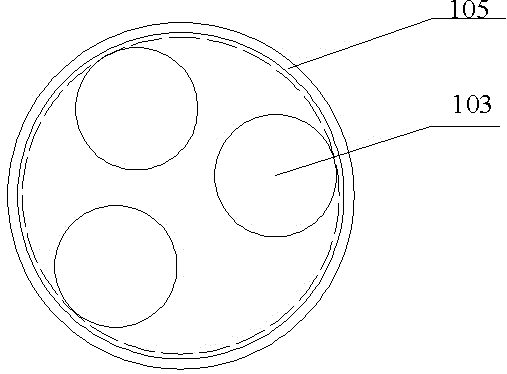

[0023] see figure 1 , the magnetron sputtering device of the present invention includes a magnetron sputtering chamber 101, which is a cylindrical or cuboid container that can form a closed space, and its left and right side walls are respectively provided with an air inlet 1011 and an air inlet 1012, and the air inlet The gas port 1012 is connected with a vacuum pump 1013; the sputtering target 103 and the target material 104 are located in the lower part of the magnetron sputtering chamber; the magnet 1041 is a permanent magnet located at the bottom of the sputtering target in the magnetron sputtering chamber, and the magnetic field strength is 10 -2 ~1T; the movable substrate table 102 is located in the upper part of the magnetron sputtering chamber and can move up and down, and a substrate 1021 is arranged on the opposite surface of it and the sputtering target 103; the protective cover 105 is located in the magnetron sputtering chamber and placed Between the target materi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com