Multilayer composite structure flexible decorative finish product and production method thereof

A flexible veneer, multi-layer composite technology, used in coatings, building structures, and biocide-containing paints, etc., can solve the problem of functional, cost-effective decoration, flexibility, flame retardancy and environmental protection. and other problems to achieve the effect of good decorative effect, unique craftsmanship and natural color transition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Embodiment 1 imitation shale

[0049] First, molds are reproduced using natural or pre-processed shale models according to market and customer needs. Prepare finish varnish, color surface color slurry and base color flame retardant and anti-mildew slurry. The components of surface color slurry include:

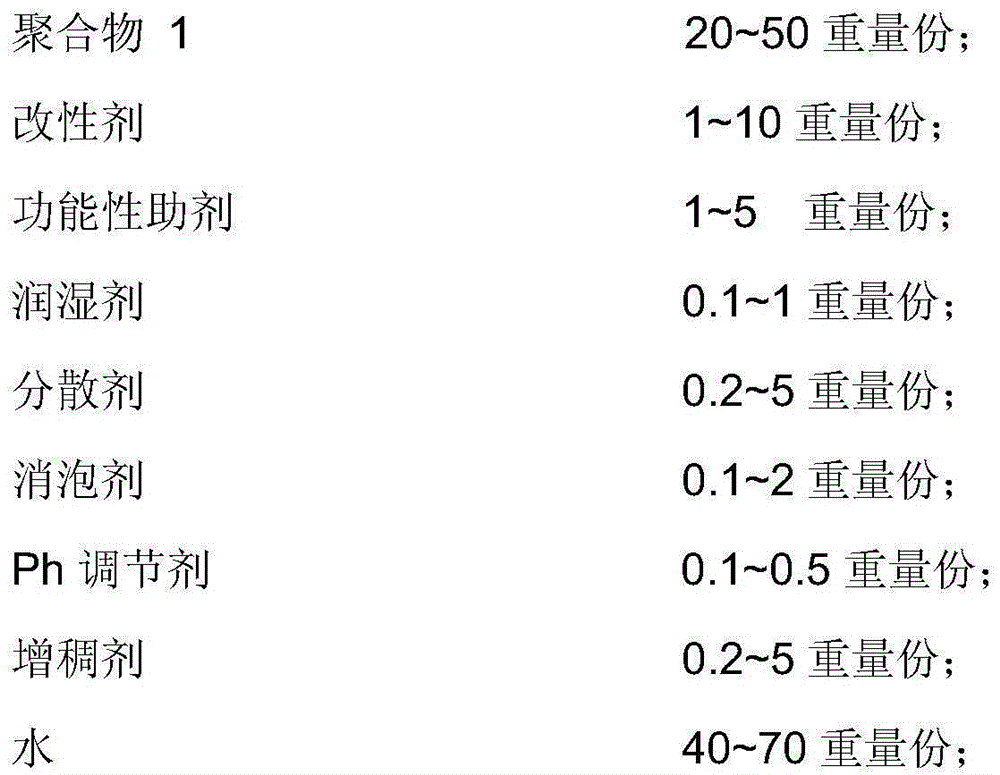

[0050] Composition A component weight ratio is:

[0051]

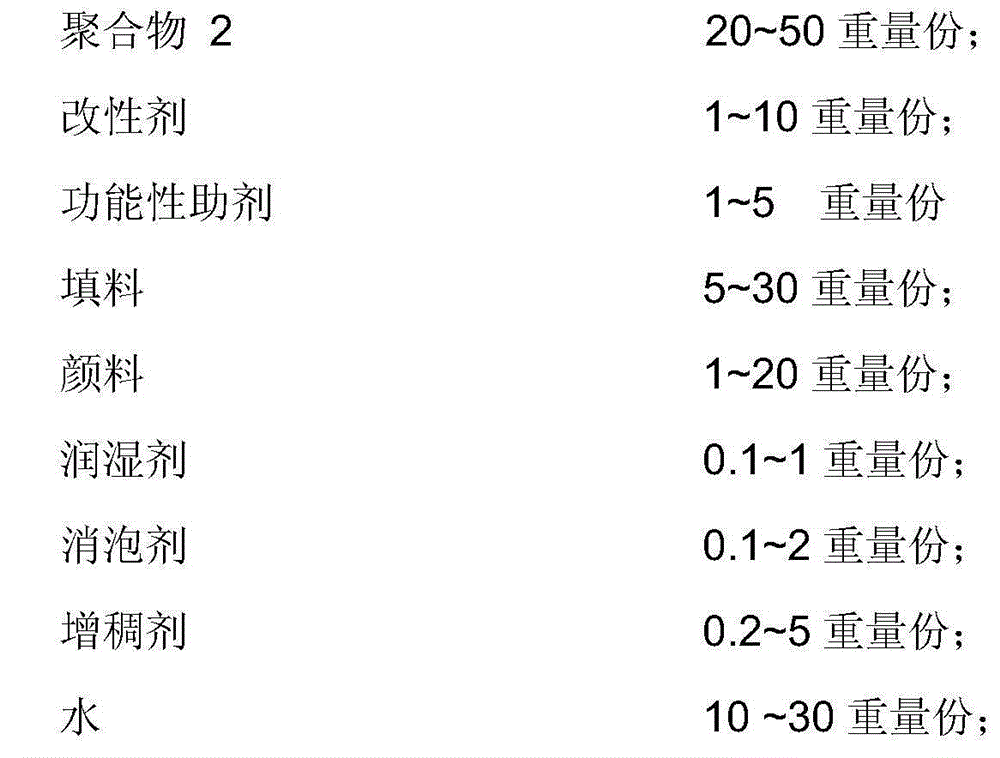

[0052] Composition B component weight ratio is:

[0053]

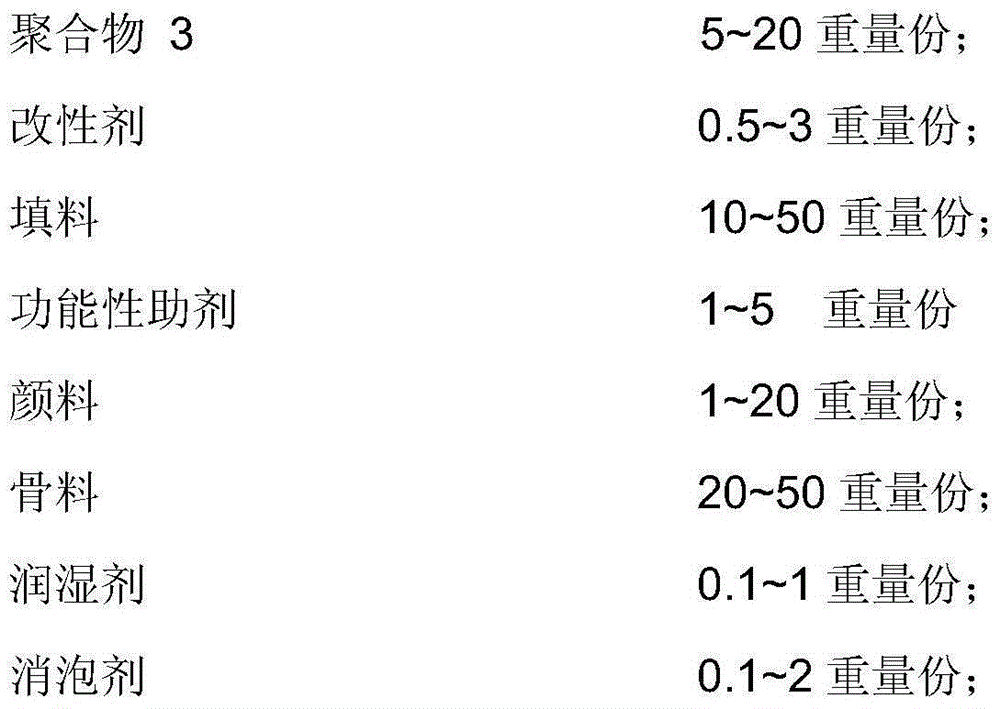

[0054] The weight ratio of the corresponding composition C component is:

[0055]

[0056]

[0057] Using water as the overcoat diluent, prepare the overcoat slurry with a viscosity of 90ku and the base color slurry with a fluidity of 210mm, pass through the corresponding equipment, pay attention to spraying in order, and then scrape and coat it on the silicone mold to form an overcoat -- Surface color layer-base color layer-grid cloth layer, four-layer structure;

[0058] Then vibrate and fuse, spread the grid brush to spread the adhesion,...

Embodiment 2

[0060] Embodiment 2 Italy Travertine

[0061] First, molds are reproduced using natural or pre-processed Italian travertine models according to market and customer needs. Formulate a finish varnish, a top-color paste and a base-color paste, the top-color paste components comprising:

[0062] Composition A component weight ratio is:

[0063]

[0064] Composition B component weight ratio is:

[0065]

[0066]

[0067] The weight ratio of the corresponding composition C component is:

[0068]

[0069] Prepare the surface color slurry with a viscosity of 85ku and the base color slurry with a fluidity of 190mm, through the corresponding equipment, pay attention to spraying in order, and then scrape and coat it on the silicone mold to form a surface color paste layer-base color paste layer-grid cloth layer ,Three-tier structure;

[0070] Then vibrate and fuse, spread the grid brush to spread the adhesion, clean up the excess slurry, and keep the overall thickness at ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com