Storage battery internal resistance measuring method and circuit, health status detection method and system

A technology of health status and measurement method, which is applied in the direction of measuring electricity, measuring electrical variables, measuring resistance/reactance/impedance, etc., can solve problems such as reducing system reliability, failure of operating power supply, doubling of maintenance workload, etc., to improve operation Reliability and safety, accurate and stable measurement results, and accurate internal resistance measurement results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

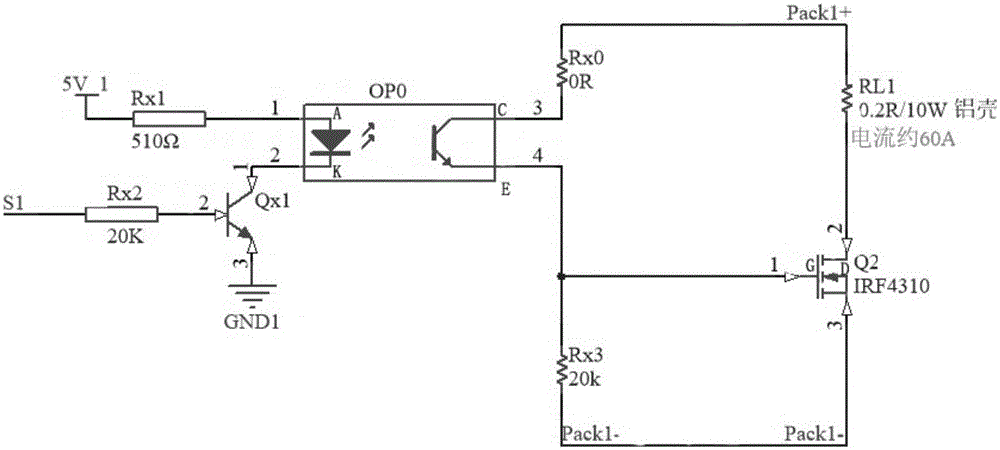

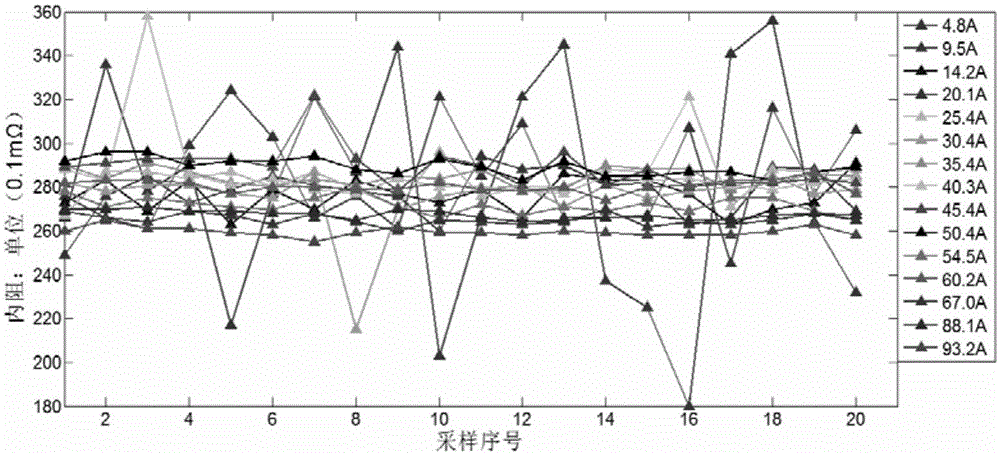

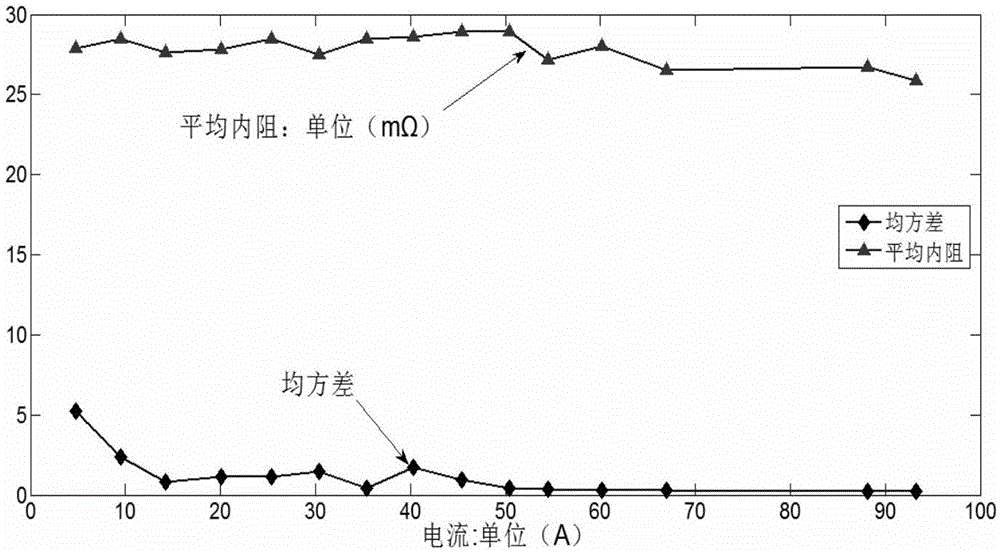

[0065] The discharge of the battery is a chemical oxidation reaction, and the charging is a chemical reduction reaction. From the perspective of electrical principles, the internal resistance not only determines the power supply capacity and capacity of the battery, but also is the most important parameter that characterizes the health status of the battery. In the prior art, the internal resistance is measured by the following two methods based on the mechanism of equivalent resistance: 1) DC discharge method; 2) AC signal injection method. Because the storage battery has a capacitive effect, the internal resistance measured by the AC signal injection method is affected by factors such as frequency and dielectric, and the measurement effect is not ideal and unstable. The DC discharge method can effectively avoid the influence of battery capacitance, and the measurement result is accurate. The DC discharge method is to discharge the battery with a large current instantaneously...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com