Laser machining device and system for producing optical display device

A laser processing and optical display technology, applied in optics, identification devices, nonlinear optics, etc., can solve problems affecting product processing accuracy, production line pollution, and difficulty in complete removal, so as to prevent production line pollution, expand effective area, and inhibit adhesion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

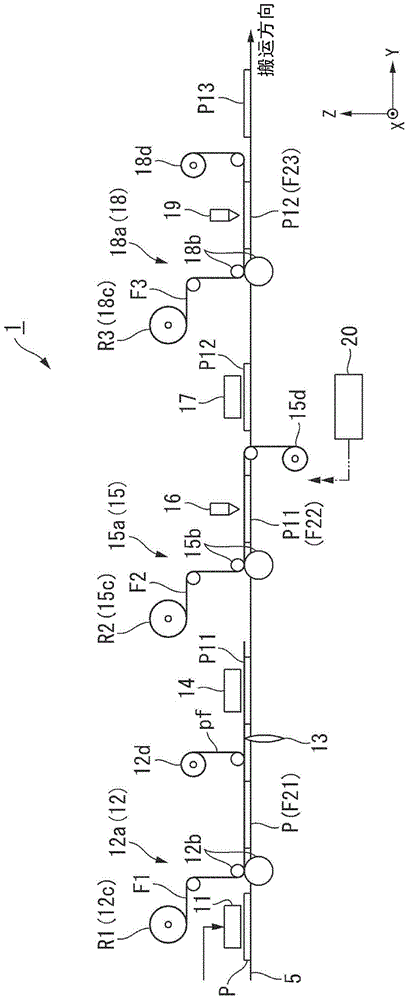

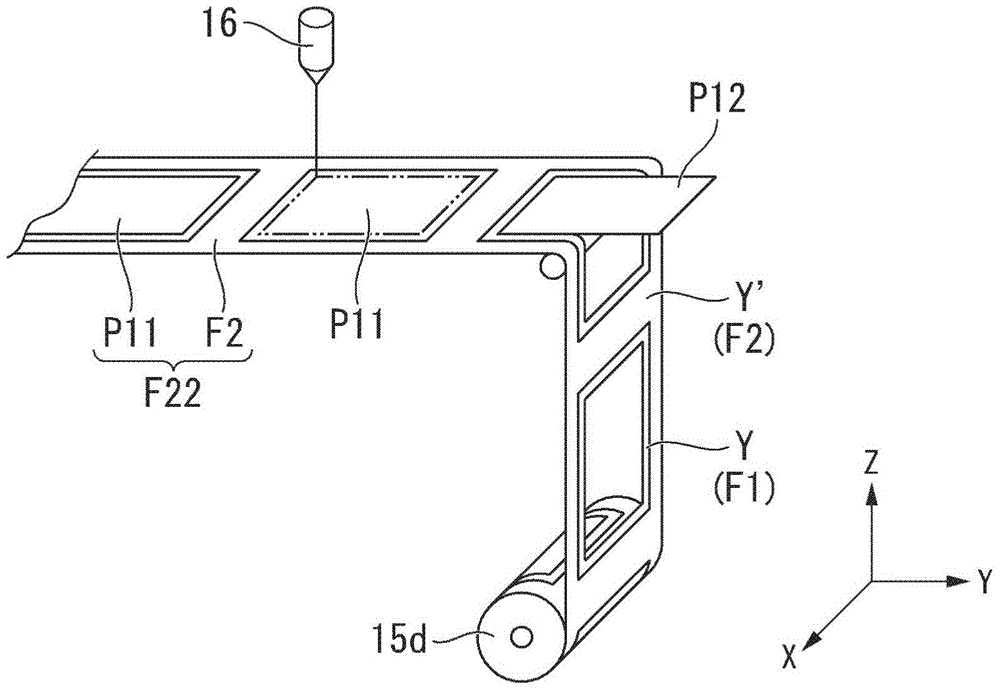

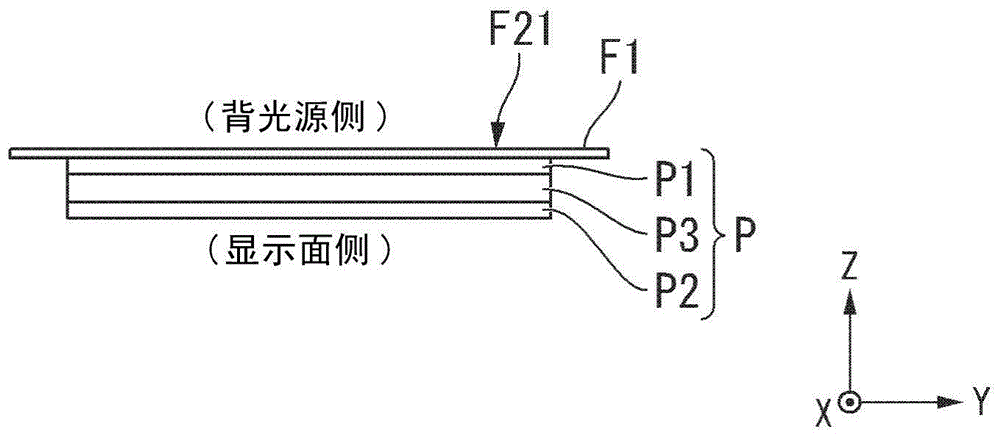

[0055] Hereinafter, embodiments of the present invention will be described with reference to the drawings. In this embodiment, as a production system of an optical display device, a film bonding system constituting a part thereof will be described. In each drawing, an XYZ rectangular coordinate system is set. The X direction represents the width direction of the optical display element (liquid crystal panel). The Y direction represents the conveyance direction of the optical display element. The Z direction represents a direction perpendicular to the X direction and the Y direction.

[0056] figure 1 The schematic structure of the film bonding system (production system of an optical display device) 1 of this embodiment is shown. The film bonding system 1 bonds a sheet-shaped optical member such as a polarizing film, a retardation film, or a brightness enhancement film to a panel-shaped optical display element such as a liquid crystal panel or an organic EL panel. The film...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com