Multi-core optical fiber and multi-core optical fiber cable

一种多芯光纤、纤芯的技术,应用在多芯光纤、包层光纤、束光导纤维等方向,能够解决曲率半径小、弯曲损耗大等问题,达到减少弯曲损耗、高耐热性的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

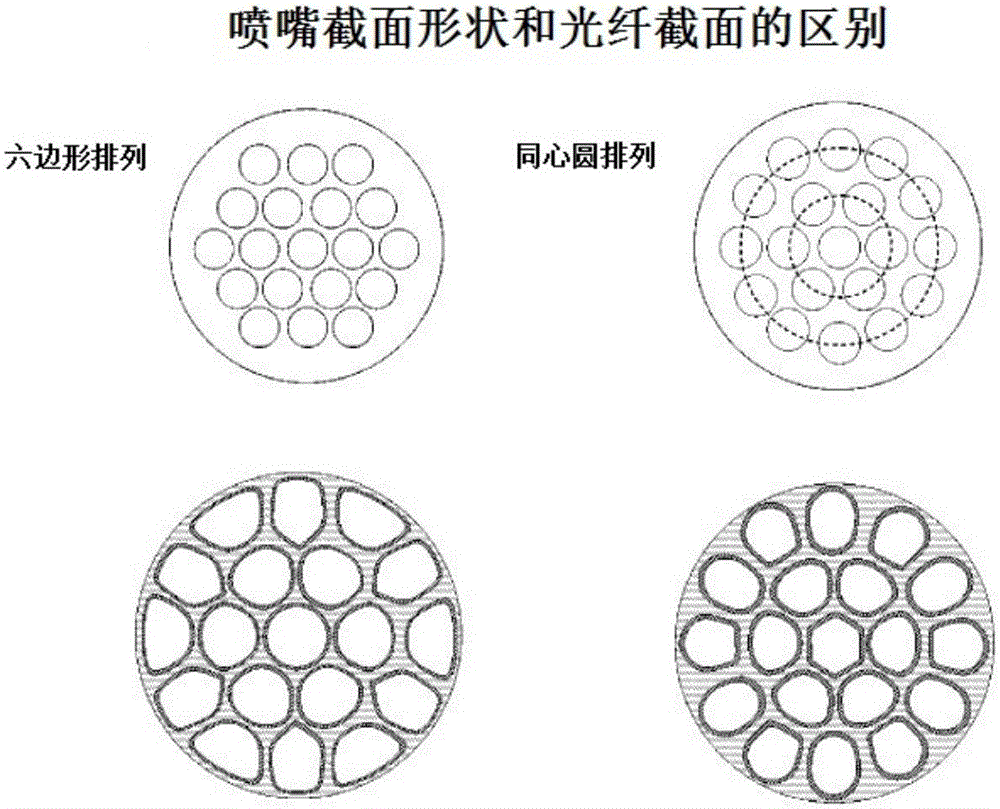

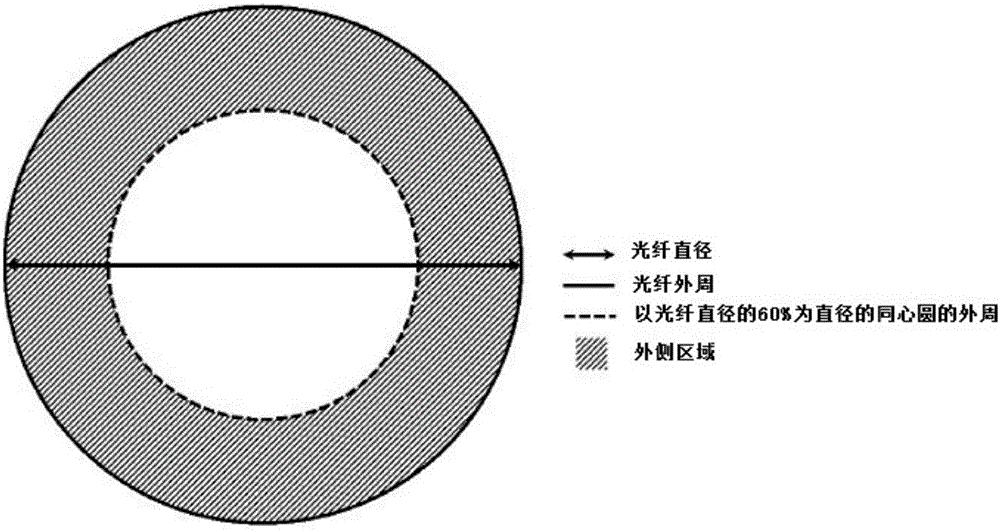

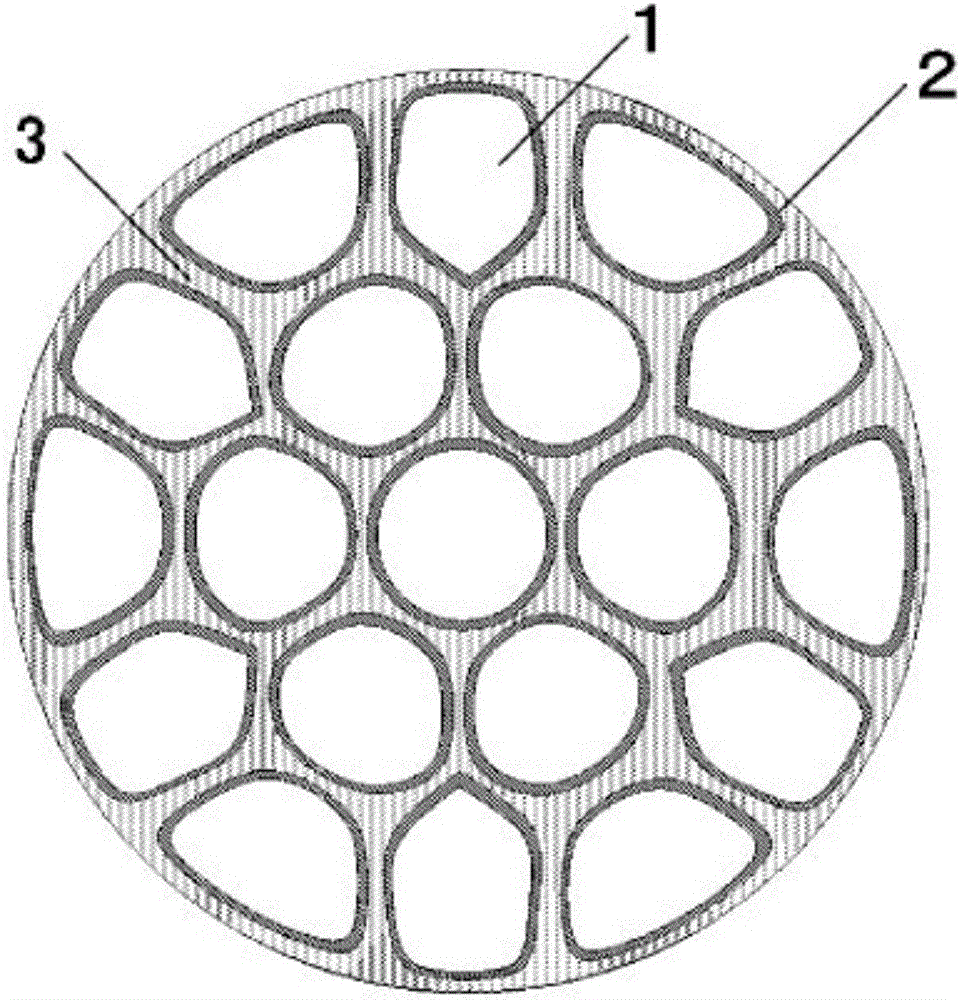

[0160] Using PMMA (refractive index 1.492) as the core material, using 2,2,2-trifluoroethyl methacrylate (3FM) / 2-(perfluorooctyl)ethyl methacrylate (17FM) / MMA / methacrylic acid (MAA) (51 / 30 / 18 / 1 (mass %)) copolymer (FM1) (refractive index 1.417) is used as cladding material, uses Vdf / TFE / HFP (48 / 43 / 9 (mass %) %)) copolymer (refractive index 1.375, heat of fusion of crystallization is 14mJ / mg) as the sea material, respectively melting the core material of 86 mass%, the cladding material of 5 mass%, and the sea material of 9 mass%, feeding 220 ℃ spinning head, the spinning nozzle with 19 nozzle holes arranged in a hexagonal shape and the funnel-shaped spinneret are combined for spinning, 2-fold stretching, and a multi-core plastic with 19 optical transmission fiber cores is obtained. optical fiber. The proportion of the total cross-sectional area of the core in the cross-section of the multi-core optical fiber is 86.6%, and the proportion of the total cross-sectional area of ...

Embodiment 2

[0165] Except using Vdf / TFE / HFP (48 / 43 / 9 (mass %)) copolymer (refractive index 1.375, heat of fusion of crystallization is 14mJ / mg) as the cladding material, according to the same method as in Example 1 to obtain poly core plastic optical fiber. In the cross-section of the obtained multi-core plastic optical fiber, the proportion of the total cross-sectional area of the core was 87.0%, and the proportion of the total cross-sectional area of the core in the outer region of the cross-section of the multi-core optical fiber was 85.9%.

[0166] The outer diameter of the multi-core plastic optical fiber coated with polyethylene is 2.2mm, which is cut into a section of 1m in length, and the emitted light amount is measured in the same way as in Example 1. The emitted light amount is 250.8nA respectively. (P0.1), 218.4nA (P0.65), and the light intensity ratio (P0.65 / 0.1) is 0.87, regardless of whether it is incident on any light with a large numerical aperture or a small numerica...

Embodiment 3

[0169] A multi-core plastic optical fiber was obtained in the same manner as in Example 1 except for using a spinning nozzle in which nozzle holes were arranged in concentric circles. The cross-section of the obtained multi-core optical fiber accounted for 82.0% of the total cross-sectional area of the core, and the percentage of the total cross-sectional area of the core in the outer region of the cross-section of the multi-core optical fiber was 80.3%. Figure 6 A schematic diagram showing the cross-sectional shape of the obtained multi-core plastic optical fiber is shown.

[0170] The outer diameter of the multi-core plastic optical fiber coated with polyethylene is 2.2mm, which is cut into a section of 1 m in length, and the emitted light amount is measured in the same way as in Example 1. The result is that the emitted light amount is 245.3 nA respectively. (P0.1), 200.3nA (P0.65), and the light ratio (P0.65 / 0.1) is 0.82.

[0171] Detailed results are shown in Table ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com