Method for synthesis of double-casing layer carbon nanometer hollow polyhedron by metal-organic framework as template

A metal-organic framework and compound technology, applied in the field of synthesizing double-shell carbon nano-hollow polyhedron, can solve the problems of cumbersome preparation process, inability to realize large-scale production, difficult nano-template, etc., and achieve simple process, easy large-scale production, wide The effect of the application foreground

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

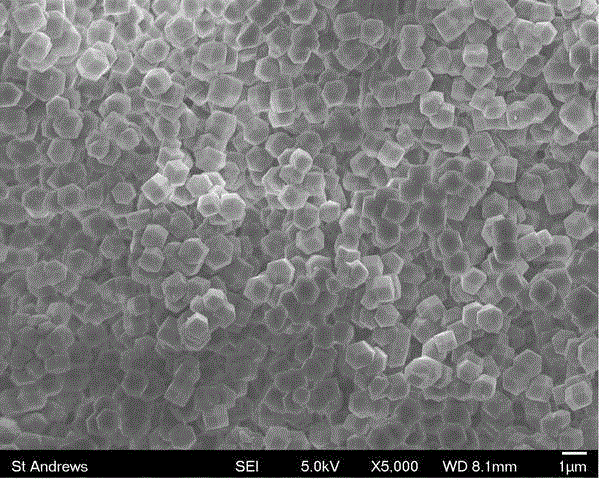

[0022] (1) Prepare 30 mL of methanol solution of zinc nitrate hexahydrate (2M) and 10 mL of methanol solution of 2-methylimidazole (12 M), mix them at room temperature, stir for 2 minutes and then let stand for reaction for 24 hours. After the reaction, wash and centrifuge repeatedly with methanol for 3 times, dry and collect to obtain the white powder of zinc-based zeolite imidazolate metal-organic framework compound material;

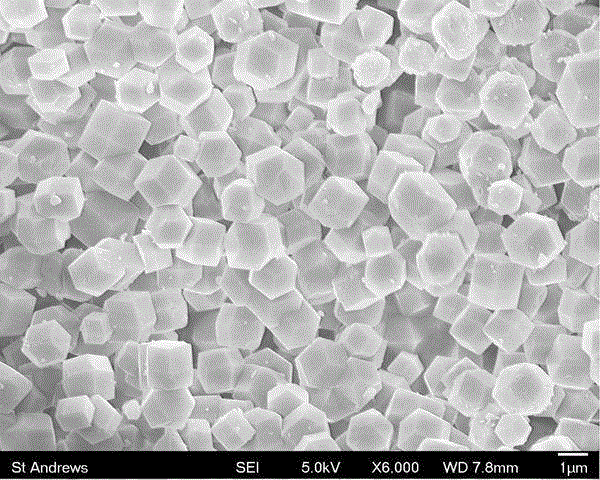

[0023] (2) Disperse the zinc-based zeolite imidazolate metal-organic framework compound material prepared in step (1) in 30 mL of methanol solution (1M) of cobalt nitrate hexahydrate, and then add 10 mL of 2-methylimidazole in methanol solution (8M) , stirred at room temperature for 24 hours. After the reaction, wash and centrifuge repeatedly with ethanol for 3 times, dry and collect cobalt / zinc-based zeolite imidazolate metal-organic framework core-shell structure purple-red powder;

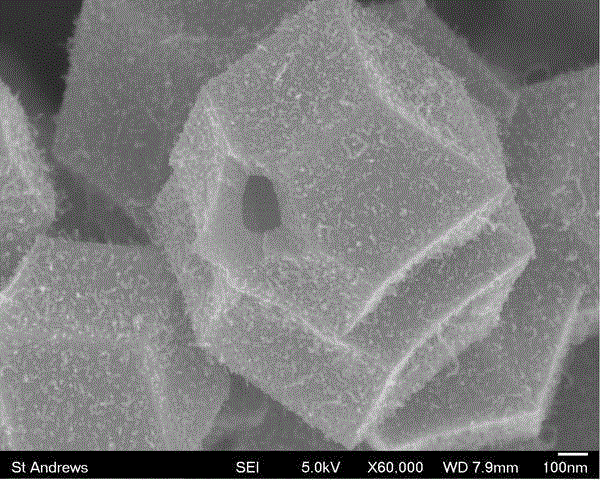

[0024] (3) Heat the cobalt / zinc-based zeolite imidazolate metal-o...

Embodiment 2

[0027] (1) Prepare 30mL methanol solution of zinc nitrate hexahydrate (2M) and 10mL methanol solution of 2-methylimidazole (12M), mix them at room temperature, stir for 2 minutes and react at 120°C for 24 hours. After the reaction, wash and centrifuge repeatedly with methanol for 3 times, dry and collect to obtain the white powder of zinc-based zeolite imidazolate metal-organic framework compound material;

[0028] (2) with embodiment 1 step (2);

[0029] (3) with embodiment 1 step (3);

[0030] (4) With embodiment 1 step (4), the average outer diameter of the hollow nanoparticles in the black powder is about 3 μm, the average thickness of the shell is 280nm, the shell is graphitized carbon, the thickness is 40nm, and there is a shorter carbon Nanotubes grow with an inner shell of amorphous carbon. The specific surface area of the powder is 638m 2 g -1 , the total pore volume is 0.428m 3 g -1 .

Embodiment 3

[0032] (1) with embodiment 1 step (1);

[0033] (2) Disperse the zinc-based zeolite imidazolate metal-organic framework compound material prepared in step (1) in 10 mL of methanol solution (1M) of cobalt nitrate hexahydrate, and then add 10 mL of 2-methylimidazole in methanol solution (2M) , stirred at room temperature for 24 hours. After the reaction, wash and centrifuge repeatedly with ethanol for 3 times, dry and collect cobalt / zinc-based zeolite imidazolate metal-organic framework core-shell structure purple-red powder;

[0034] (3) with embodiment 1 step (3);

[0035] (4) With embodiment 1 step (4), the average outer diameter of the hollow nanoparticles in the gained black powder is about 900nm, and the average thickness of the shell is 100nm, and the shell is graphitized carbon, and the thickness is 20nm, with shorter carbon on it. Nanotubes grow with an inner shell of amorphous carbon. The specific surface area of the powder is 554m 2 g -1 , the total pore volume...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average outer diameter | aaaaa | aaaaa |

| The average thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com