High-efficiency multipurpose sewage treatment agent and sewage treatment method using the same

A kind of sewage treatment agent and high-efficiency technology, applied in the direction of water/sewage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of semi-stop production, high energy consumption, high energy consumption, etc., and achieve low cost, The effect of wide source of raw materials and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

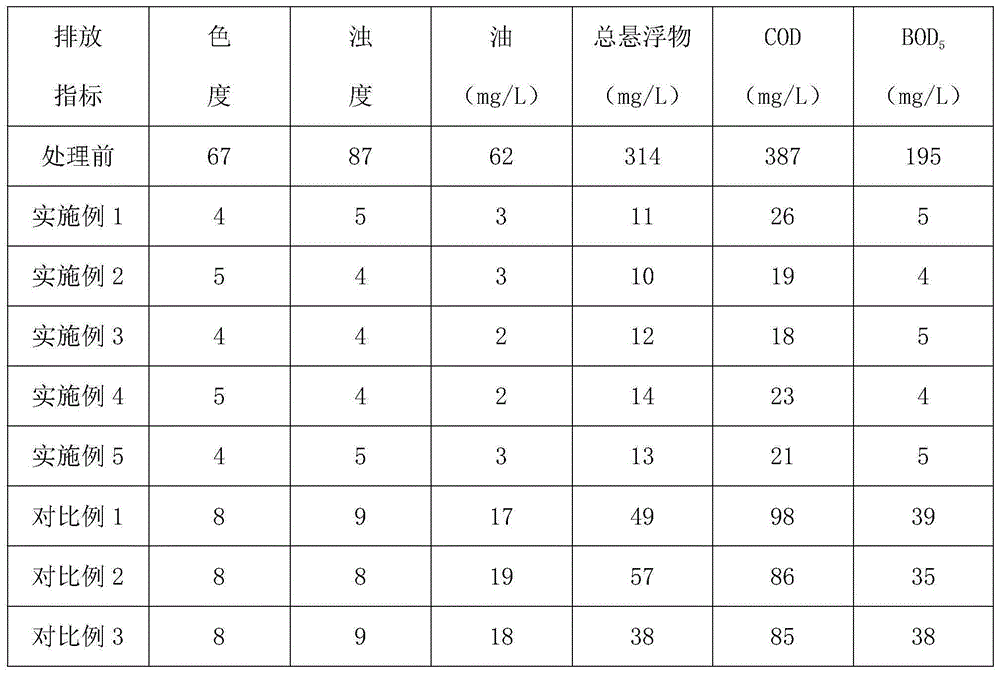

Examples

Embodiment 1

[0028] A high-efficiency and multi-purpose sewage treatment agent. The raw materials in parts by weight are: 80 parts of activated sludge from urban sewage treatment plants, 40 parts of tobermorite, 40 parts of pinaceae plant waste, and 7 parts of concentrated sulfuric acid with a mass concentration of 98%. , 20 parts of sodium hydroxide, 30 parts of polyaluminum phosphate, and 25 parts of polysilicate ferric sulfate.

[0029] The preparation method of described high-efficiency multi-purpose sewage treatment agent, concrete steps are:

[0030] (1) Add water to the activated sludge of urban sewage treatment plant to make its water content 60%; grind the particle size of tobermorite to 30 orders; crush the particle size of pinaceae plant waste to 300 orders;

[0031] (2) mix the tobermorite obtained in the step (1) with concentrated sulfuric acid, and obtain the first mixed product after stacking for 12 hours;

[0032] (3) Mix the first mixed product with the activated sludge f...

Embodiment 2

[0036] A high-efficiency and multi-purpose sewage treatment agent. The raw materials in parts by weight are: 100 parts of activated sludge from urban sewage treatment plants, 60 parts of tobermorite, 60 parts of pinaceae plant waste, and 5 parts of concentrated sulfuric acid with a mass concentration of 95%. , 15 parts of sodium hydroxide, 25 parts of polyaluminum sulfate, and 20 parts of polysilicate ferric sulfate.

[0037]The preparation method of described high-efficiency multi-purpose sewage treatment agent, concrete steps are:

[0038] (1) Add water to the activated sludge of urban sewage treatment plant to make its water content 75%; grind the particle size of tobermorite to 65 orders; crush the particle size of pinaceae plant waste to 200 orders;

[0039] (2) mix the tobermorite obtained in the step (1) with concentrated sulfuric acid, and obtain the first mixed product after stacking for 18 hours;

[0040] (3) Mix the first mixed product with the activated sludge of ...

Embodiment 3

[0044] A high-efficiency and multi-purpose sewage treatment agent. The raw materials in parts by weight are: 120 parts of activated sludge from urban sewage treatment plants, 80 parts of tobermorite, 80 parts of pinaceae plant waste, and 3 parts of concentrated sulfuric acid with a mass concentration of 90%. , 10 parts of sodium hydroxide, 20 parts of polyaluminum phosphate, and 15 parts of polysilicate ferric sulfate.

[0045] The preparation method of described high-efficiency multi-purpose sewage treatment agent, concrete steps are:

[0046] (1) Add water to the activated sludge of urban sewage treatment plant to make its moisture content 90%; crush the particle size of tobermorite to 100 mesh; crush the particle size of pinaceae plant waste to 100 mesh;

[0047] (2) mix the tobermorite obtained in the step (1) with concentrated sulfuric acid, and obtain the first mixed product after stacking for 12 hours;

[0048] (3) Mix the first mixed product with the activated sludge ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com