A zero-discharge process for desulfurization wastewater

A desulfurization wastewater and zero-discharge technology, which is applied in the direction of gaseous effluent wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem of heavy metal ions without self-purification and biodegradability, animal and plant life activities Harm and other issues to achieve the effect of improving competitiveness and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

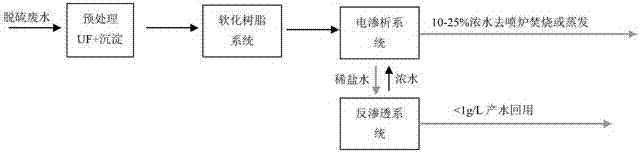

[0017] With reference to the accompanying drawings, the desulfurization wastewater entering the process of the present invention is first processed in step (1): the desulfurization wastewater is treated with a sedimentation tank, softening resin and ultrafiltration system; the desulfurization wastewater first enters the sedimentation tank for precipitation, and the effluent enters the ultrafiltration system, the ultrafiltration system produces water into the softening resin, and then enters the treatment of step (2), the concentrated water enters the sedimentation tank for sedimentation, and the regeneration solution of the softened resin also enters the sedimentation tank for sedimentation. After step (1), the water quality reaches the following indicators : Sodium sulfate=5-20% (mass percentage), TSS<1mg / L; COD<100mg / L;.

[0018] (2) The electrodialysis system is used for treatment, and the electrodialysis system is divided into fresh water, concentrated water and extreme wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com