Lustrous light gray raw glaze special for nixing pottery and preparation method thereof

A kind of Nixing pottery, light gray technology, applied in a kind of glaze of Nixing pottery and its preparation field, can solve the problems of contradicting the product concept, covering the surface effect, low firing temperature, etc., and achieve easy large-scale production and preparation Simple method and easy to control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

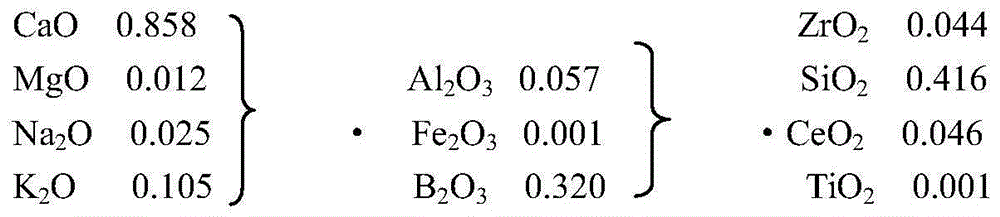

Image

Examples

Embodiment 1

[0020] The preparation method of the glossy light gray raw material glaze special for Nixing pottery of the present embodiment comprises the following steps:

[0021] Step 1: Weigh the following raw materials with an accuracy of 0.1 gram: 7.8 parts of zirconium silicate, 9 parts of cerium oxide, 30 parts of calcium borate, 12 parts of calcite, 4 parts of zinc oxide, 8 parts of quartz, 10 parts of feldspar, 8 parts of Luotu and 14 parts of Haibi blue material are mixed evenly to form a mixed solid raw material;

[0022] Step 2, according to the ratio of mixed solid ball stone: raw material: water = 2:1:0.8, add ball mill to mix ball mill respectively, and the time of mixing ball mill is 6h / kg to form slurry;

[0023] Step 3, detecting the fineness of the slurry;

[0024] Step 4, sieve the qualified slurry for fineness detection to remove iron, the mesh of the slurry when sieving is ≥200 mesh, and obtain the glaze slurry;

[0025] Step five, age the glaze slurry for later use....

Embodiment 2

[0029] The preparation method of the glossy light gray raw material glaze special for Nixing pottery of the present embodiment comprises the following steps:

[0030] Step 1: Weigh the following raw materials with an accuracy of 0.1 gram: 8.5 parts of zirconium silicate, 10.6 parts of cerium oxide, 33 parts of calcium borate, 14 parts of calcite, 5.6 parts of zinc oxide, 10.8 parts of quartz, 15 parts of feldspar, 15 parts of Luotu, 17 parts of Haibi blue material, mix evenly to form a mixed solid raw material;

[0031] Step 2, according to the ratio of mixed solid ball stone: raw material: water = 2: 1: 0.8, respectively add ball mill to mix ball mill, and the time of mixing ball mill is 8h / kg to form slurry;

[0032] Step 3, detecting the fineness of the slurry;

[0033] Step 4, sieve the qualified slurry for fineness detection to remove iron, the mesh of the slurry when sieving is ≥200 mesh, and obtain the glaze slurry;

[0034] Step five, age the glaze slurry for later u...

Embodiment 3

[0038] The preparation method of the glossy light gray raw material glaze special for Nixing pottery of the present embodiment comprises the following steps:

[0039] Step 1: Weigh the following raw materials with an accuracy of 0.1 gram: 8 parts of zirconium silicate, 10 parts of cerium oxide, 32 parts of calcium borate, 13 parts of calcite, 5 parts of zinc oxide, 10 parts of quartz, 12 parts of feldspar, vitamin 10 parts of Luotu, 15 parts of Haibi blue material, mix evenly to form a mixed solid raw material;

[0040] Step 2, according to the ratio of mixing solid ball stone: raw material: water = 2:1:0.8, add the ball mill to mix ball milling, and the time of mixing ball milling is 7h / kg to form a slurry;

[0041] Step 3, detecting the fineness of the slurry;

[0042] Step 4, sieve the qualified slurry for fineness detection to remove iron, the mesh of the slurry when sieving is ≥200 mesh, and obtain the glaze slurry;

[0043] Step five, age the glaze slurry for later use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com