Kaolin printing and dyeing sludge geopolymer material and preparation method thereof

A technology of geopolymer and printing and dyeing sludge, which is applied in cement production and other directions, can solve the problems of heavy metal enrichment and environmental hazards, and achieve the effect of sealing and overcoming the difficulties of recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

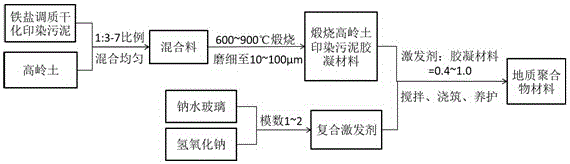

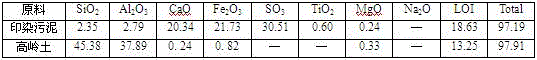

[0026] The preparation method of kaolin printing and dyeing sludge geopolymer material of the present invention comprises the following steps:

[0027] (1) Blending 1 part of dried printing and dyeing sludge and 7 parts of kaolin, calcining at 800°C for 3 hours, cooling and grinding to 10-100 μm, to obtain calcined kaolin printing and dyeing sludge cementitious material;

[0028] (2) Mix sodium water glass and sodium hydroxide, control its modulus to 1.5, make a composite activator, and age for 24 hours;

[0029] (3) At a room temperature of 20°C, 5 parts of calcined kaolin printing and dyeing sludge cementitious material and 4 parts of composite activator were stirred evenly to make a slurry;

[0030] (4) The prepared slurry is poured into a mold with a cover to prevent water evaporation, and a geopolymer material of kaolin printing and dyeing sludge is obtained. Its 7-day compressive strength is 32 MPa, and its 28-day compressive strength is 58 MPa. The leaching amount of h...

Embodiment 2

[0032] The preparation method of kaolin printing and dyeing sludge geopolymer material of the present invention comprises the following steps:

[0033] (1) Blending 1 part of dried printing and dyeing sludge and 5 parts of kaolin, calcining at 800°C for 3 hours, cooling and grinding to 10-100 μm, to obtain calcined kaolin printing and dyeing sludge cementitious material;

[0034] (2) Mix sodium water glass and sodium hydroxide, control its modulus to 1.5, make a composite activator, and age for 24 hours;

[0035] (3) At a room temperature of 20°C, 10 parts of calcined kaolin printing and dyeing sludge cementitious material and 9 parts of composite activator were stirred evenly to make a slurry;

[0036] (4) The prepared slurry is poured into a mold with a cover to prevent water evaporation, and a geopolymer material of kaolin printing and dyeing sludge is obtained. Its 7-day compressive strength is 24 MPa, and its 28-day compressive strength is 47 MPa. The leaching amount of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com