Fatty tertiary amine diurea small molecule gelling agent and its thixotropic molecular gel

A tertiary amine diurea-like molecular gel technology, which is applied in colloid chemistry, colloid chemistry, urea derivatives preparation, etc., can solve the problem of thixotropic molecular gel of fatty tertiary amine urea, which has not been reported publicly.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Taking the preparation of the fatty tertiary amine diurea small molecule gelling agent with the following structural formula as an example, the preparation method is as follows:

[0034]

[0035] Put 2.64g (0.01mol) of 4,4'-diisocyanato-3,3'-dimethylbiphenyl in a 250mL round bottom flask, add 150mL of dichloromethane, fully stir to dissolve, then add 3.16g (0.02mol) 1-diethylamino-4-aminopentane, stirred and reacted at room temperature under a nitrogen atmosphere for 16 hours, separated by suction filtration with a sand core funnel to obtain a white solid, which was washed with benzene, tetrahydrofuran successively Fully heat-washed for 3 to 4 times, and fully vacuum-dried at room temperature to obtain a white powder fat tertiary amine diurea small-molecule gelling agent.

[0036] The resulting gelling agent structure was 1 H NMR, 13 C NMR, MS characterization confirmation, the specific data are as follows:

[0037] 1 H NMR (d6-DMSO) δ (ppm): 0.92-0.95 (12H, t, J...

Embodiment 2

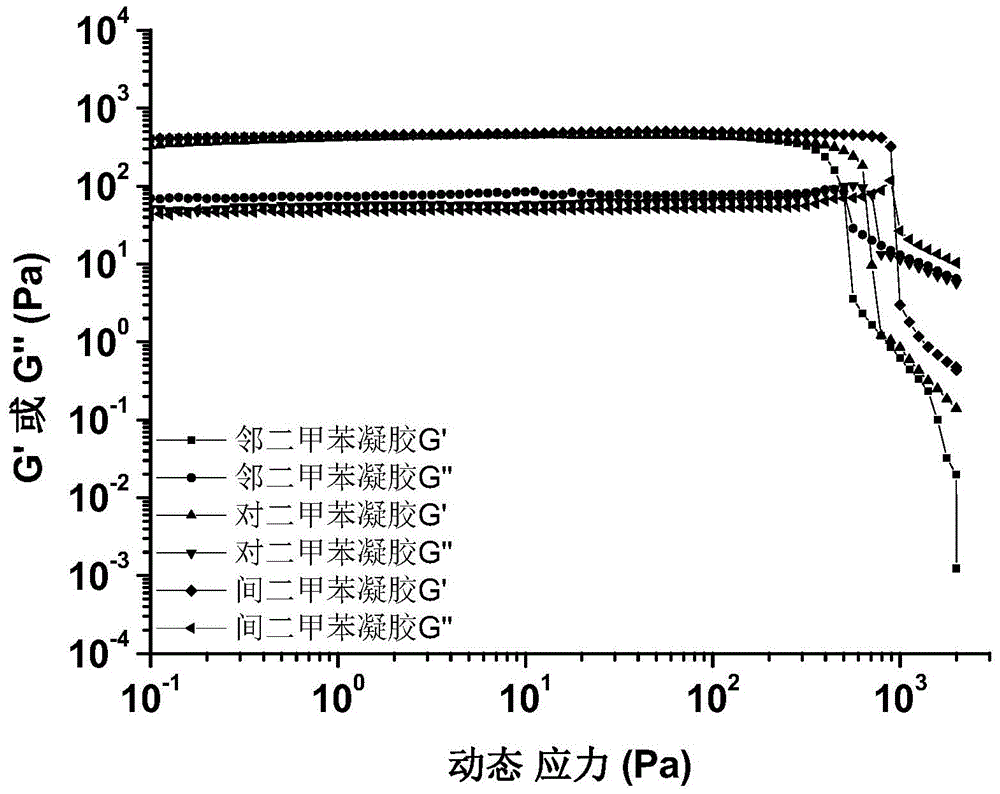

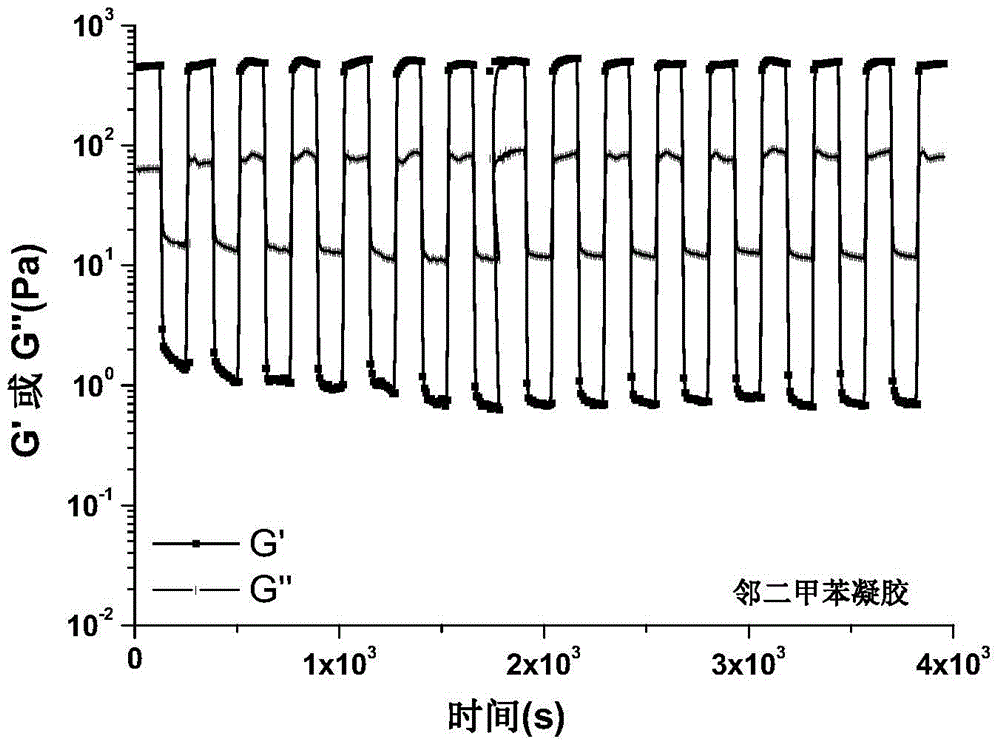

[0039] Place 0.04g (0.07mmol) of the aliphatic tertiary amine diurea small molecule gelling agent of Example 1 and 2.0mL o-xylene in a 3mL sample bottle with a diameter of 10mm, seal it and ultrasonicate at room temperature for 30 minutes, and then heat until gelling. The coagulant is completely dissolved to form a clear solution, then naturally cooled to room temperature, and placed at room temperature until a stable transparent gel is formed, that is, a thixotropic molecular gel (called o-xylene gel). When stimulated by shaking, the gel turns into a sol state, and when the shaking stops, the sol state returns to the gel state, showing a typical reversible shear phase transition.

Embodiment 3

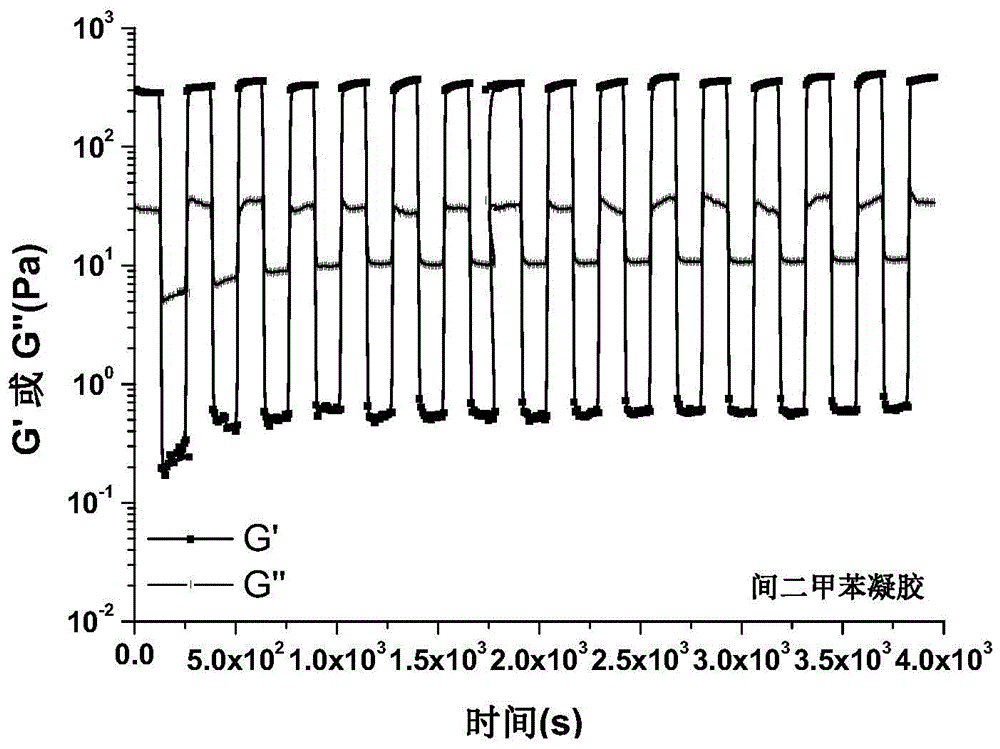

[0041] In Example 2, the used o-xylene was replaced with an equal volume of m-xylene, and other steps were the same as in Example 2 to obtain a thixotropic molecular gel (called m-xylene gel).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com