A kind of maleic anhydride grafted styrene block copolymer blending modified polyurethane hot melt adhesive and preparation method thereof

A polyurethane hot-melt adhesive and styrene block technology, which is applied in the field of modified polyurethane, can solve the problems of high cost and poor water resistance, and achieve the effects of improved compatibility, high peel strength and high quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] A kind of preparation method of maleic anhydride grafted styrene block copolymer blending modified polyurethane hot-melt adhesive of the present invention, comprises the following steps:

[0026] 1) Preparation of polyurethane hot melt adhesive: add polyether diol, isocyanate and catalyst at 65-75°C, stir slowly for 0.5h, raise the temperature to 10°C, stir at a constant speed, react for 2-2.5h, add 1,4-butyl Glycol and defoamer, stir evenly, vacuumize to remove air bubbles, and obtain polyurethane hot melt adhesive;

[0027] In step 1), the feeding is carried out at 65-75°C, and after 0.5h of heat preservation and stirring, the temperature is raised to 10°C for prepolymerization, which can effectively prevent implosion and make the quality of the obtained polyurethane prepolymer higher; after prepolymerization, add expansion Chain agent 1,4-butanediol for chain extension;

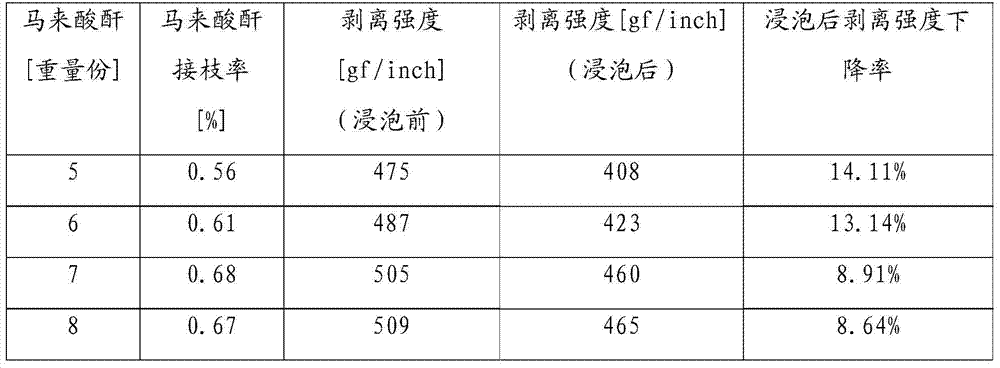

[0028] 2) Preparation of maleic anhydride grafted styrene block copolymer: add naphthenic oil, ...

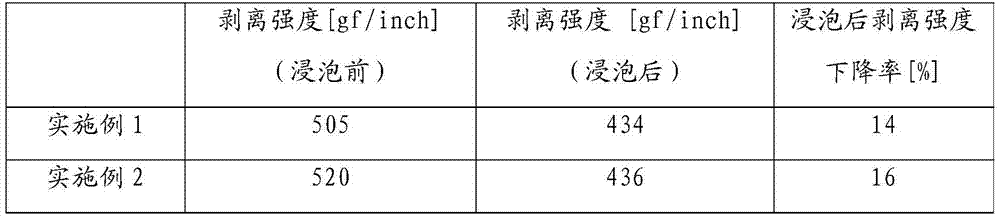

Embodiment 1

[0032] 1) Preparation of polyurethane hot-melt adhesive: MDI and PTMG are mixed in a molar ratio of 2.0:1, and 1.0% of the total mass of PTMG and MDI is added to carry out prepolymerization reaction to obtain a prepolymer. Add 1,4-butanediol and 0.8% T-105 antifoaming agent in the total mass of the prepolymer in an equimolar amount with PTMG, stirred evenly, and vacuumed at a vacuum degree of 0.09-0.1MPa to remove bubbles until no bubbles were obtained. Polyurethane hot melt adhesive;

[0033] 2) prepare maleic anhydride grafted styrene block copolymer: the styrene-isoprene-styrene copolymer (SIS) of the naphthenic oil of 40 weight parts, the maleic anhydride of 6 weight parts, 50 weight parts ), 1 part by weight of antioxidant was added to a kneader or a screw extruder at the same time, and reacted for 2 hours at 150°C to obtain a maleic anhydride grafted styrene-isoprene-styrene copolymer (abbreviated as MAH-SIS);

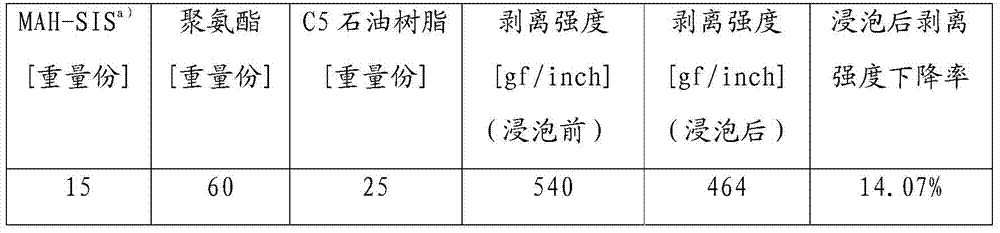

[0034] 3) Blending: After shear melting 30 parts by weight...

Embodiment 2

[0036] 1) Preparation of polyurethane hot-melt adhesive: MDI and PPG are mixed in a molar ratio of 2.0:1, and 1.0% of the total mass of PPG and MDI is added to carry out prepolymerization with dimorphinyl diethyl ether to obtain a prepolymer. 1,4-butanediol and 0.8% T-105 antifoaming agent in an equimolar amount of PPG and the total mass of the prepolymer are stirred evenly, and vacuumized to remove bubbles until there are no bubbles at a vacuum degree of 0.09-0.1MPa to obtain Polyurethane hot melt adhesive;

[0037] 2) prepare maleic anhydride grafted styrene block copolymer: the styrene-isoprene-styrene copolymer (SIS) of the naphthenic oil of 40 weight parts, the maleic anhydride of 7 weight parts, 50 weight parts ), 1 part by weight of antioxidant was added to a kneader or a screw extruder at the same time, and reacted for 2 hours at 150°C to obtain a maleic anhydride grafted styrene-isoprene-styrene copolymer (abbreviated as MAH-SIS);

[0038] 3) Blending: After shear me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com