Method for regulating micro structure of Ti-Zr-Nb-Cu-Be-system amorphous composite material

A technology of ti-zr-nb-cu-be and amorphous composite materials, which is applied in the microstructure field of titanium-based amorphous composite materials, can solve the problems of long melt processing time and limited ability to control the microstructure of the second phase. Achieve the effect of achieving nucleation rate, eliminating the introduction of impurities and pollutants, and avoiding reactions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

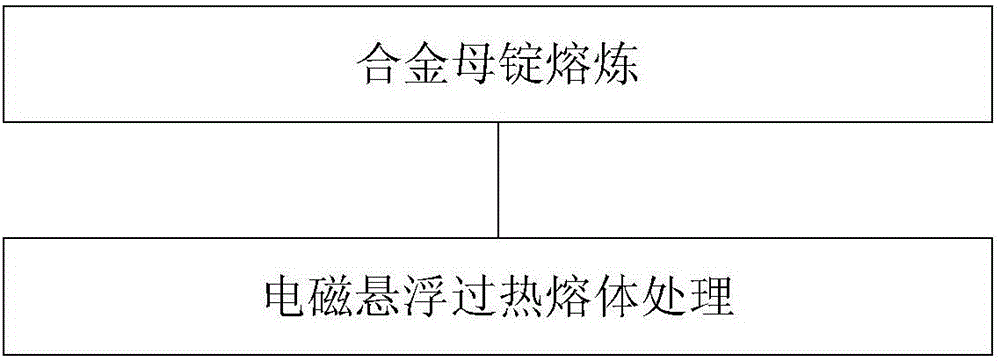

[0028] This embodiment is a method for regulating the microstructure of the Ti-Zr-Nb-Cu-Be system amorphous composite material

[0029] The composition of the amorphous composite material is Ti 44 Zr 20 Nb 12 Cu 5 be 19 , control the overheating time to obtain Ti-based amorphous composites with different solidification morphology. The concrete process of this embodiment is:

[0030] Step 1, alloy master ingot smelting: Ti, Zr, Nb, Cu, Be with a purity greater than 99.9% are smelted in two steps in a high-vacuum non-consumable arc melting furnace under the protection of argon gas at 0.5 atmospheres:

[0031] The first step is to smelt Ti with a high melting point 44 Zr 20 Nb 12 Alloy ingot:

[0032] During smelting, the arc melting chamber system needs to be evacuated to a high vacuum first, then filled with argon, and the oxygen-absorbing titanium ingot is smelted for 2 minutes to effectively remove the remaining oxygen in the furnace cavity.

[0033] Melting Ti with...

Embodiment 2

[0044] This embodiment is a preparation method of a titanium-based amorphous composite material, and the composition of the amorphous composite material is Ti 48 Zr 20 Nb 12 Cu 5 be 15 , control the overheating time to obtain Ti-based amorphous composites with different solidification morphology. The concrete process of this embodiment is:

[0045] Step 1, alloy master ingot smelting: Ti, Zr, Nb, Cu, Be with a purity greater than 99.9% are smelted in two steps in a high-vacuum non-consumable arc melting furnace under the protection of argon gas at 0.5 atmospheres:

[0046] The first step is to smelt Ti with a high melting point 48 Zr 20 Nb 12 Alloy ingot:

[0047] During smelting, the arc melting chamber system needs to be evacuated to a high vacuum first, then filled with argon, and the oxygen-absorbing titanium ingot is smelted for 2 minutes to effectively remove the remaining oxygen in the furnace cavity.

[0048] Melting Ti with high melting point 48 Zr 20 Nb 1...

Embodiment 3

[0059] This embodiment is a preparation method of a titanium-based amorphous composite material, and the composition of the amorphous composite material is Ti 50 Zr 20 Nb 12 Cu 5 be13 , control the overheating time to obtain Ti-based amorphous composites with different solidification morphology. The concrete process of this embodiment is:

[0060] Step 1, alloy master ingot smelting: Ti, Zr, Nb, Cu, Be with a purity greater than 99.9% are smelted in two steps in a high-vacuum non-consumable arc melting furnace under the protection of argon gas at 0.5 atmospheres:

[0061] The first step is to smelt Ti with a high melting point 48 Zr 20 Nb 12 Alloy ingot:

[0062] During smelting, the arc melting chamber system needs to be evacuated to a high vacuum first, then filled with argon, and the oxygen-absorbing titanium ingot is smelted for 2 minutes to effectively remove the remaining oxygen in the furnace cavity.

[0063] Melting Ti with high melting point 50 Zr 20 Nb 12 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com