Rotor system for hybrid kinetic energy power generation device

A power generation device and kinetic energy technology, applied in the direction of generating mechanical power with physical force, mechanisms for generating mechanical power, machines/engines, etc., can solve the problems of lack of scientific operability, inability to meet high torque, and application range stop, etc., to achieve The effect of large torque, large moment of inertia, and small starting torque

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

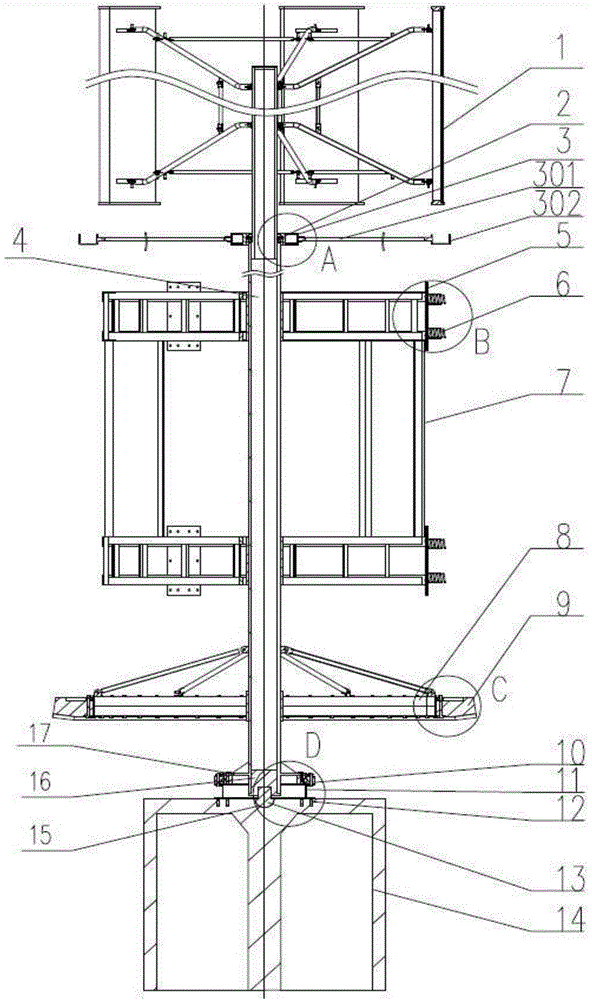

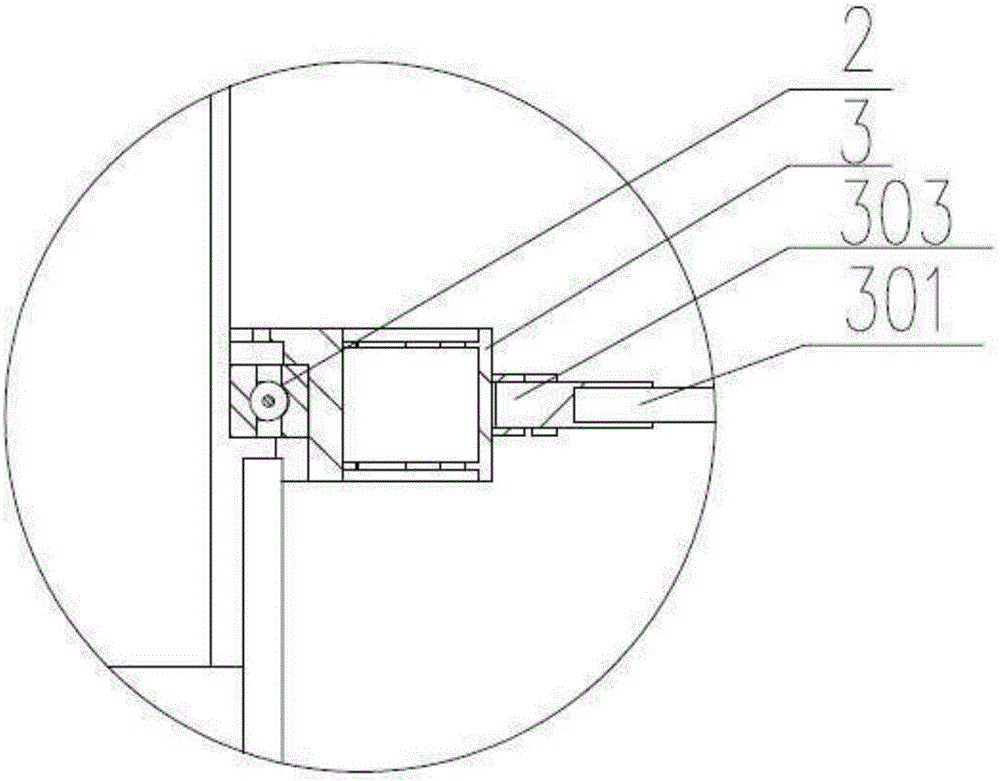

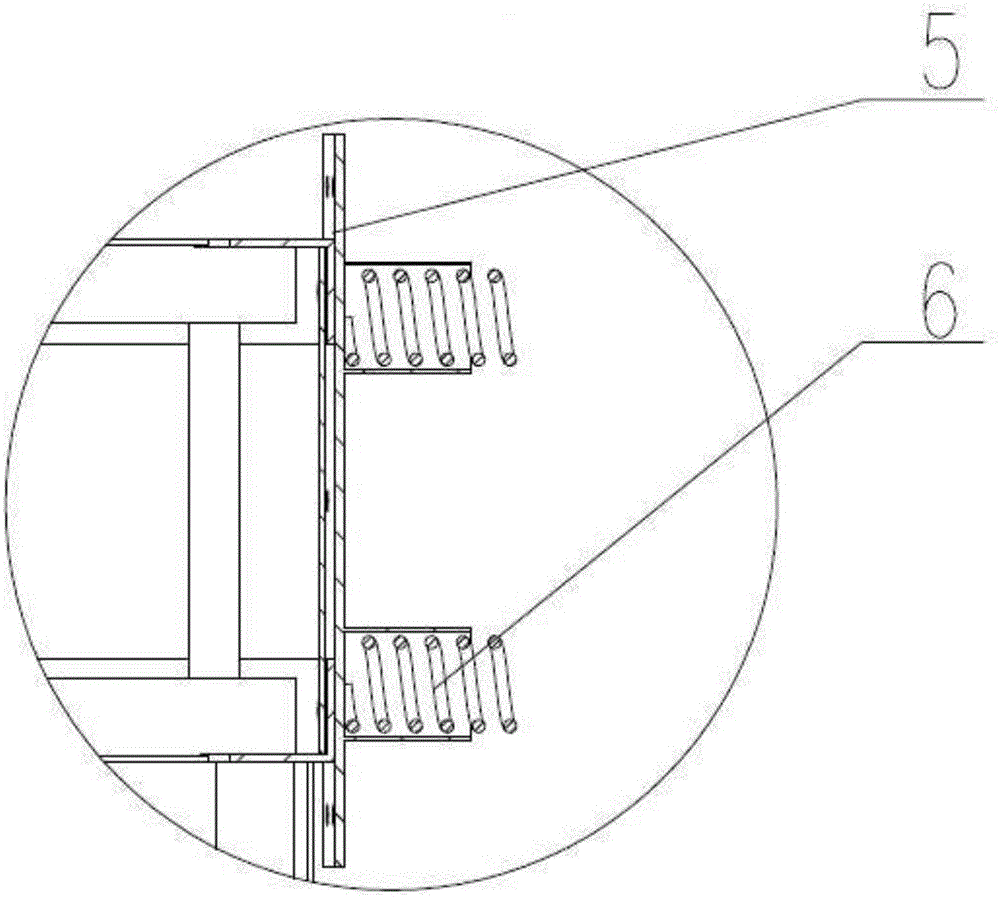

[0025] like Figure 1 to Figure 5 As shown, a rotor system for a hybrid kinetic energy generating device includes a hollow main transmission shaft 4, which is located at the bottom of the main transmission shaft 4, and is connected to a shaft sleeve 16 inside the main transmission shaft 4, and a hemispherical gyro rotor 13 and shaft The sleeve 16 is connected; along the outer circumference of the main transmission shaft 4, the adjustment wheel 3, the squirrel-cage frame 7, the gear plate 8 and the slewing bearing 10 are respectively installed from top to bottom, and the squirrel-cage frame 7 is passed through the frame by the discs arranged up and down. A multi-layer rotor structure is formed in series; a rolling bearing 2 for cooperating with the outer periphery of the main transmission shaft 4 is arranged inside the adjustment wheel 3; a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com