Raman sensing temperature measurement system in double-end injection annular structure, and Raman sensing temperature measurement method

A technology of Raman sensing temperature measurement and ring structure, applied in the field of temperature measurement system, can solve the problems of not being able to fully and truly reflect the temperature information along the optical fiber, increasing temperature measurement error, slow measurement error, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

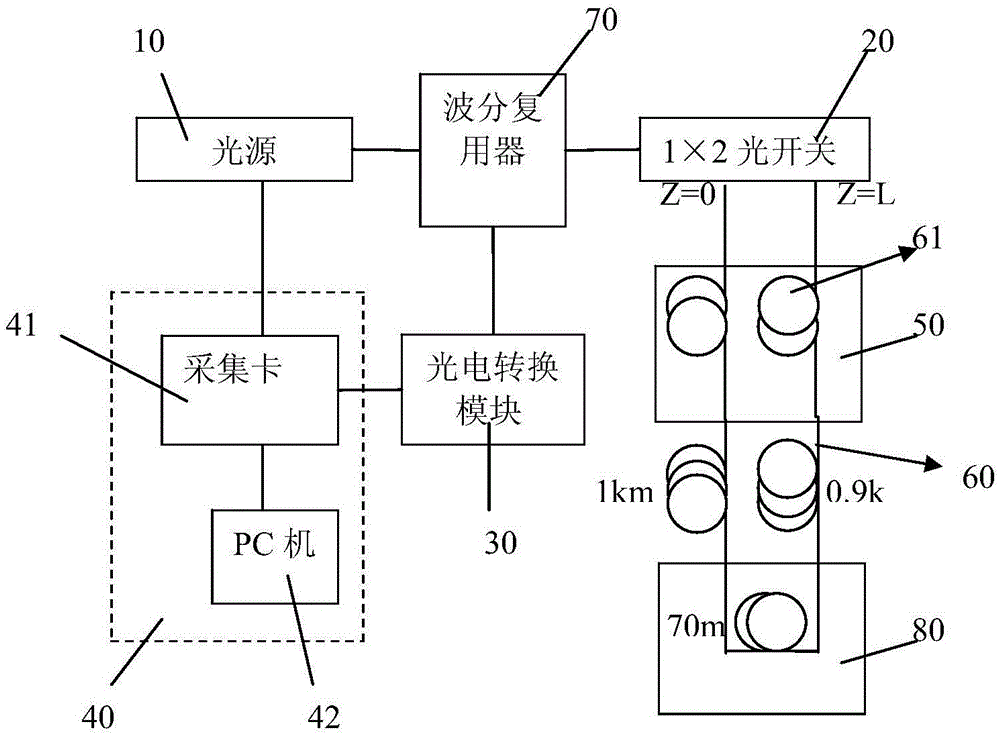

[0061] Please check figure 1 , in order to eliminate the influence of the optical fiber loss factor described in the background technology on temperature measurement, the present invention adopts a double-end injection ring structure to build a double-end injection ring structure Raman sensing temperature measurement system, the system includes a light source, a wavelength division multiplexer The light source is connected with the optical signal of the wavelength division multiplexer, the optical signal of the photoelectric conversion module is connected with the optical signal of the wavelength division multiplexer and the electrical signal of the data acquisition and processing module; It includes a 1x2 optical switch, the first and last ends of the sensing fiber are respectively connected to the 1x2 optical switch and the sensor optical fiber is arranged in a ring structure, the wavelength division multiplexer is connected to the 1x2 optical switch, and the 1x2 optical swit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com