Cu2O@CuO semi-core-shell structure nano composite material and preparation method therefor

A technology of nanocomposite materials and core-shell structure, applied in the field of composite materials and their preparation, can solve the problems of unfavorable electron transport, complex process, high cost, etc., and achieve the effect of simple process, low preparation cost and mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

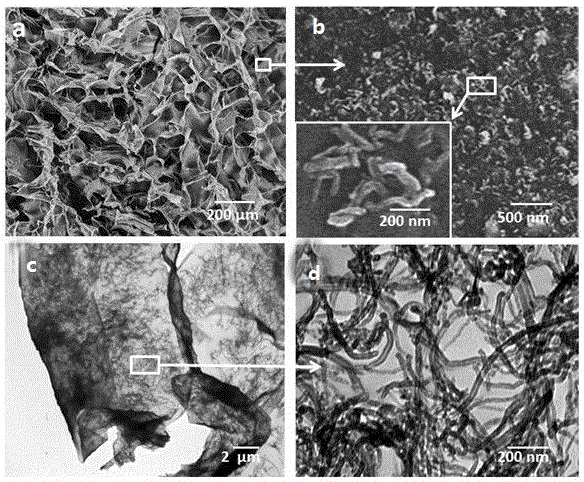

[0032] 0.1g of CNTs was ultrasonically dispersed in 100mL of deionized water to prepare a CNTs dispersion. Take 1g chitosan (CS) dissolved in 100mL1% acetic acid aqueous solution to prepare 1wt.% CS solution. 8 mL of CNTs dispersion and 2 mL of CS solution were ultrasonically mixed for 5 min. Add 0.2 mL of 1% glutaraldehyde aqueous solution and stir for 15 min. The mixture was poured into the template and freeze-dried for 24 hours. Washing with water and ethanol several times and drying in vacuo yielded purified carbon sponges. The obtained carbon sponge structure is shown in Fig. from SEM figure 1 In a, it can be seen that the porous sponge structure based on CS is conducive to the adsorption of metal ions. figure 1 b is the rough structure of the CS surface after magnification, and the inset shows the CNTs protruding from the CS surface, which are used for electrical conduction in sensing. TEM figure 1 c, 1d also show CNTs embedded in CS.

[0033] Take 0.015g carb...

Embodiment 2

[0036] 0.1g of CNTs was ultrasonically dispersed in 100mL of deionized water to prepare a CNTs dispersion. Take 1g chitosan (CS) dissolved in 100mL1% acetic acid aqueous solution to prepare 1wt.% CS solution. 10mL of CNTs dispersion and 2mL of CS solution were ultrasonically mixed for 5min. Add 0.2 mL of 1% glutaraldehyde aqueous solution and stir for 15 min. The mixture was poured into the template and freeze-dried for 24 hours. Washing with water and ethanol several times and drying in vacuo yielded purified carbon sponges. Experiments have shown that changing the ratio of reactants within a certain range will not affect the material synthesis.

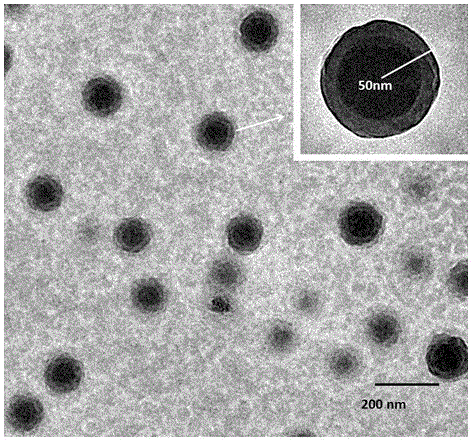

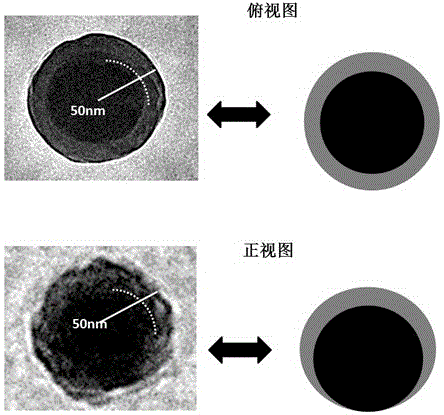

[0037] Take 0.015g carbon sponge and put it into 8mL0.1MCuSO 4 The solution was adsorbed for 24h, the remaining solution was removed, and 5mL of 0.5M NaBH was added dropwise on the surface 4 After reacting for 2 hours, the remaining solution was removed and oxidized in air for 5 hours, washed with ethanol and dried in an oven a...

Embodiment 3

[0039] 0.1g of CNTs was ultrasonically dispersed in 100mL of deionized water to prepare a CNTs dispersion. Take 1g chitosan (CS) dissolved in 100mL1% acetic acid aqueous solution to prepare 1wt.% CS solution. 8 mL of CNTs dispersion and 2 mL of CS solution were ultrasonically mixed for 5 min. Add 0.2 mL of 1% glutaraldehyde aqueous solution and stir for 15 min. The mixture was poured into the template and freeze-dried for 24 hours. Washing with water and ethanol several times and drying in vacuo yielded purified carbon sponges.

[0040] Take 0.015g carbon sponge and put it into 8mL0.1MCuSO 4 The solution was adsorbed for 24h, the remaining solution was removed, and 5mL of 0.4M NaBH was added dropwise on the surface 4 After reacting for 2 hours, the remaining solution was removed and oxidized in air for 2 hours, washed with ethanol and dried in an oven at 60°C. Obtain uniformly dispersed Cu 2 OCuO half-core-shell nanoparticles. Experiments have shown that changing the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

| Radius | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com