Contact lenses having photonic crystal structural color and manufacturing method thereof

A technology of contact lenses and photonic crystals, applied in glasses/goggles, optics, optical components, etc., can solve the problems of chemical reagents, such as human health hazards, difficulty in mass production, low production efficiency, etc., to beautify eyes, low cost, structure The effect of fewer defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

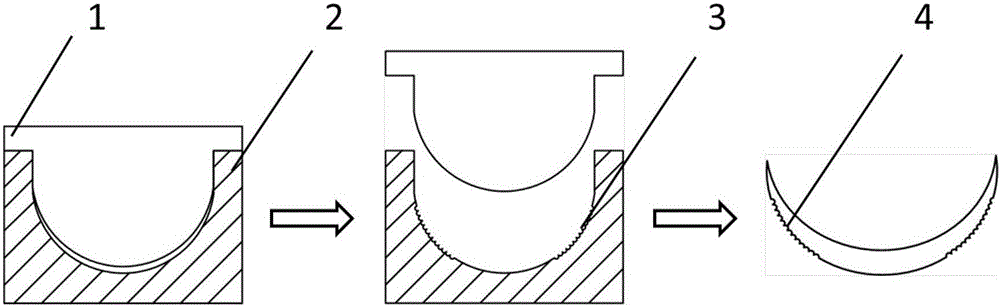

[0039] A preparation method of a contact lens with photonic crystal structural color, comprising the following steps:

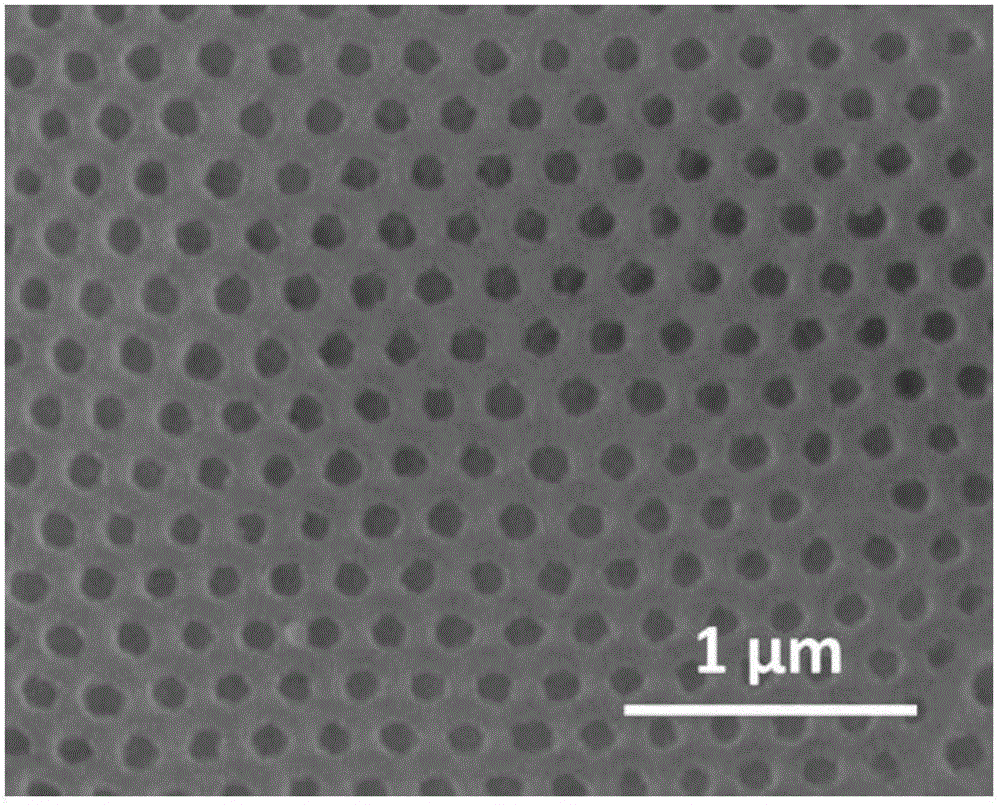

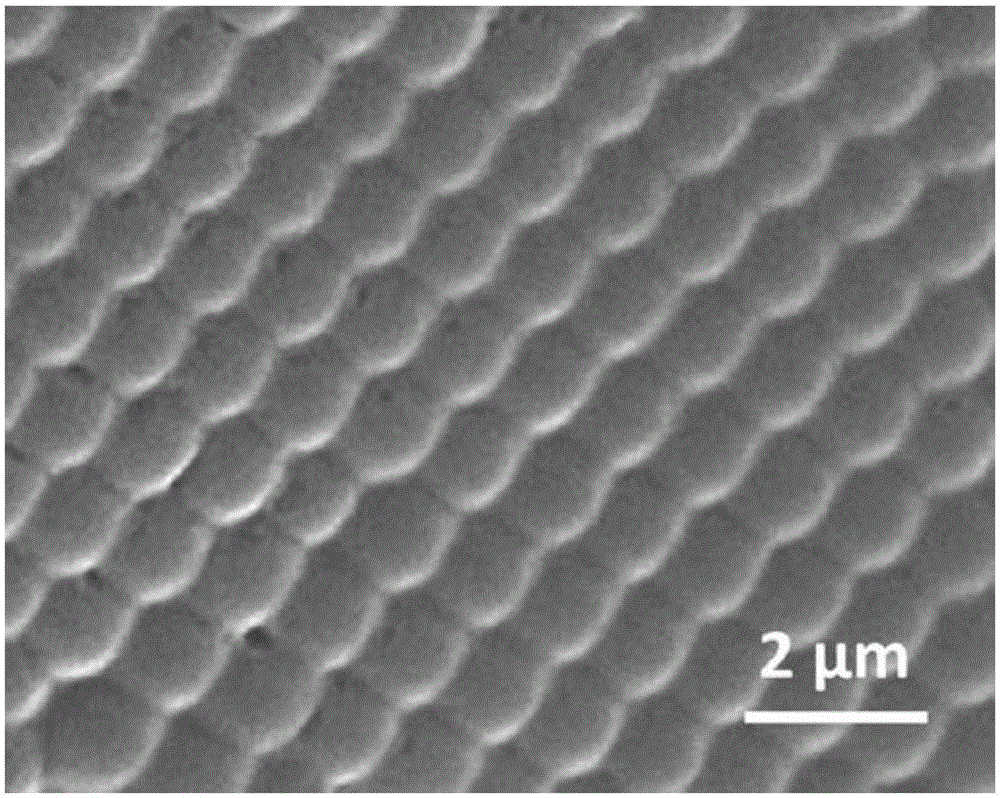

[0040] (1) Get a polypropylene material contact lens mould, this mold comprises upper mold and lower mold that can be separated, wherein, upper mold has a convex spherical surface, lower mold has a concave spherical surface, utilizes femtosecond pulse two-photon polymerization method in lower mold A photonic crystal structure layer is prepared on the concave spherical surface of the contact lens mold with a photonic crystal structure, and the photonic crystal structure is periodically arranged micro-nano-scale spherical pits, and the size of the spherical pits is 100nm;

[0041] (2) After mixing PDMS and its curing agent at a ratio of 10:1, take 100 microliters of the above mixed solution and n-hexane at a volume ratio of 1:1 and mix it as a contact lens prepolymer solution for use. Take the above prepolymer solution 100 microliters were added to the contact ...

Embodiment 2

[0047] A preparation method of a contact lens with photonic crystal structural color, comprising the following steps:

[0048] (1) Get a polystyrene material contact lens mould, this mold comprises upper mold and lower mold that can be separated, wherein, upper mold has a convex spherical surface, and lower mold has a concave spherical surface, utilize femtosecond pulse two-photon polymerization method in A photonic crystal structure layer is prepared on the convex spherical surface of the upper mold to obtain a contact lens mold with a photonic crystal structure. The photonic crystal structure is periodically arranged micro-nano-scale spherical protrusions, and the size of the spherical protrusions is 1 μm;

[0049] (2) Add contact lens prepolymer solution (obtained by mixing 50 microliters of methyl methacrylate, 1 microliter of ethylene glycol dimethacrylate, and 1 mg of ultraviolet photoinitiator) into the above-mentioned lens with photonic crystal structure In the contact...

Embodiment 3

[0054] A preparation method of a contact lens with photonic crystal structural color, comprising the following steps:

[0055] (1) Get a polycarbonate material contact lens mould, this mold comprises upper mold and lower mould, wherein, upper mold has a convex spherical surface, and lower mold has a concave spherical surface, utilize femtosecond pulse two-photon polymerization method respectively A photonic crystal structure layer is prepared on the convex spherical surface of the upper mold and the concave spherical surface of the lower mold to obtain a contact lens mold with a photonic crystal structure. The size is 50 μm;

[0056] (2) With contact lens prepolymer solution: in the mixed solution (molar ratio 30:1) of hydroxyethyl methacrylate and methylene bisacrylamide, with Irgacure2959 (mass concentration is 0.2%) as initiator, join in In the above obtained contact lens mold having a photonic crystal structure, a contact lens primary sheet containing a photonic crystal l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com