Artificial blood vessel

A technology of artificial blood vessels and single fibers, applied in the field of artificial blood vessels, can solve the problems of insufficient practicability of artificial blood vessels, achieve the effects of inhibiting blood leakage from artificial blood vessels, reducing strength deterioration, and reducing the occurrence of thrombus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

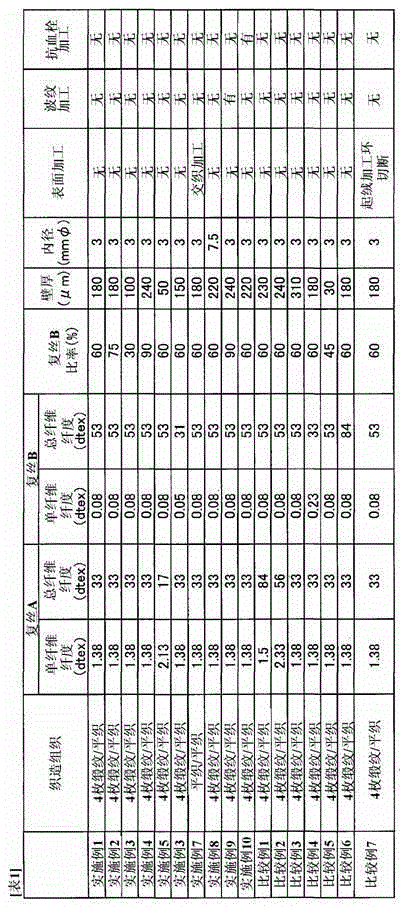

Embodiment 1

[0068] The warp and weft (back side yarns) use polyester fiber with a single fiber fineness of 1.38dtex and a total fineness of 33dtex multifilament yarn A; and a sea component polymer made of polyethylene terephthalate copolymerized with 5-sodium isophthalate Sea-island fiber composed of ethylene formate and island component polymer made of polyethylene terephthalate (ratio of sea / island (mass ratio)=20 / 80, island component number 70), single fiber fineness 7.3 dtex, total fineness 66dtex, untwisted multifilament yarn B'. The multifilament B'is formed into a multifilament B through an ultrafine treatment. Using the above warp yarns, for the multifilament yarn A and the multifilament B', respectively, the multifilament yarn A for a beam warping machine is used to make the warp weaving axis A, and the multifilament yarn B'is used to make the warp weaving axis B'. Using the above weft yarns, for the multifilament yarn A and the multifilament B', respectively, the multifilament y...

Embodiment 2

[0071] Except that the ratio of the multifilament yarn B was 75%, an artificial blood vessel including a tubular fabric was produced by the same method as in Example 1. When observing the inner wall surface of the obtained artificial blood vessel with a magnifying microscope of 100 times, it was confirmed that the multifilament yarn B formed loops and these loops existed in a dispersed state. In addition, the water permeability is 310ml / cm 2 / min, kink resistance, anti-thrombosis and cell adhesion get excellent results.

Embodiment 3

[0073] Except that the ratio of the number of single fibers of the multifilament yarn B was 30% and the wall thickness was 100 μm, an artificial blood vessel including a tubular fabric was produced by the method described in Example 1. When observing the inner wall surface of the obtained artificial blood vessel with a magnifying microscope of 100 times, it was confirmed that the multifilament yarn B formed loops and these loops existed in a dispersed state. Water permeability is 190ml / cm 2 / min, kink resistance has good results, antithrombotic properties are excellent, and cell adhesion has practical results.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Total fineness | aaaaa | aaaaa |

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com