Preparation method of indium oxide with octahedral morphology

An indium oxide and octahedral technology is applied in the field of solvothermal combined with high-temperature calcination to prepare indium oxide with octahedral morphology, which can solve the problem that the research of high-tech deep-processed products is still in its infancy, and achieves easy control of reaction parameters and economical efficiency. The effect of convenient scale-up and industrial production, cheap and easy availability of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

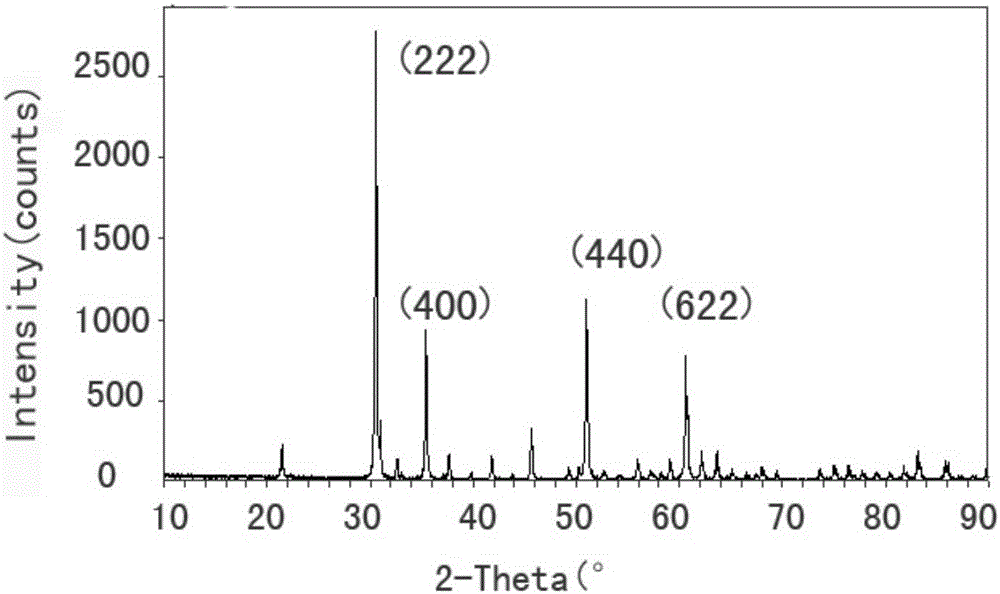

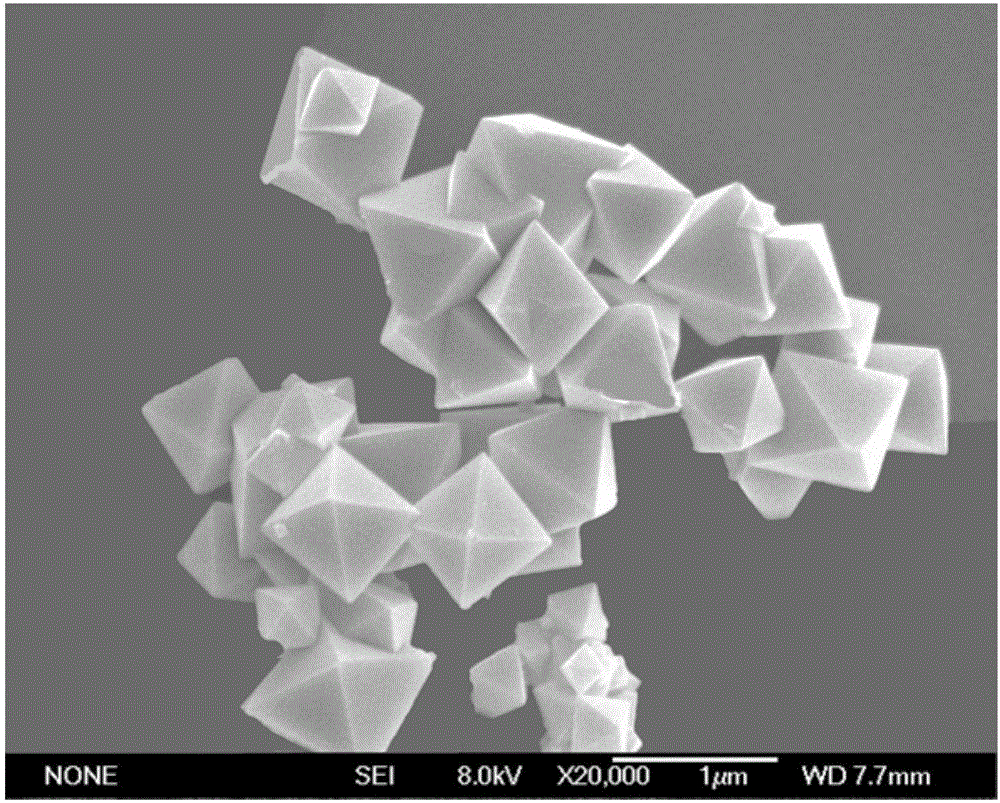

[0009] Weigh 0.2gInCl 3 4H 2 O and 0.064g urea were put into a beaker, 15mL of ethylene glycol was added, and a transparent solution was formed by magnetic stirring for 2 hours. Finally, the mixed solution was transferred to a stainless steel autoclave lined with polytetrafluoroethylene, and kept at 120°C for 24 hours. , cooled to room temperature in air, and collected samples. Wash with absolute ethanol, centrifuge, and dry in air at 80°C for 6 hours to obtain a white powder. The dried white powder was calcined in a tube furnace at 600° C. for 3 h under air condition to obtain indium oxide with octahedral morphology.

Embodiment 2

[0011] Weigh 0.2gInCl 3 4H 2 O and 0.064g urea were placed in a beaker, 15mL of ethylene glycol was added, and a transparent solution was formed by magnetic stirring for 2 hours. Finally, the mixed solution was transferred to a stainless steel autoclave lined with polytetrafluoroethylene, and kept at 160°C for 18 hours. , cooled to room temperature in air, and collected samples. Wash with absolute ethanol, centrifuge, and dry in air at 60°C for 10 h to obtain a white powder. The dried white powder was calcined in a tube furnace at 650° C. for 2 h under air condition to obtain indium oxide with octahedral morphology.

Embodiment 3

[0013] Weigh 0.2gInCl 3 4H 2 O and 0.066g urea were put into a beaker, 15mL of ethylene glycol was added, and a transparent solution was formed by magnetic stirring for 2 hours. Finally, the mixed solution was transferred to a stainless steel autoclave lined with polytetrafluoroethylene, and kept at 160°C for 18 hours. , cooled to room temperature in air, and collected samples. Wash with absolute ethanol, centrifuge, and dry in air at 80°C for 12 hours to obtain a white powder. The dried white powder was calcined in a tube furnace at 650° C. for 2 h under air condition to obtain indium oxide with octahedral morphology.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com