Nickel and cobalt production enterprise raffinate waste water deep processing recovery device

A technology of advanced treatment and recycling device, applied in the fields of metallurgical wastewater treatment, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., which can solve the inevitable pollution of the surrounding environment, the expansion of industrial sewage, and the waste of limited resources. and other problems, to achieve the effect of low labor intensity of workers, low investment and operation cost, and avoidance of secondary pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

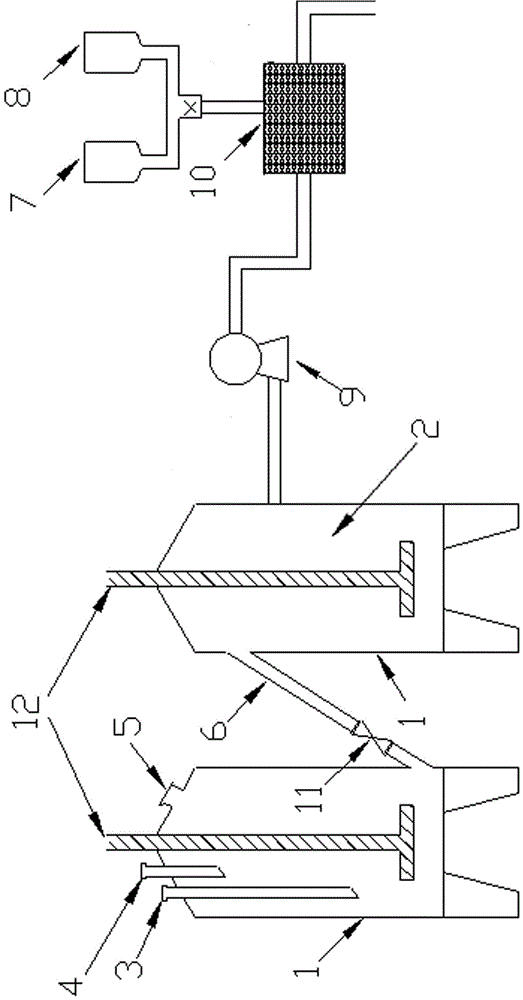

[0016] The following is combined with the accompanying drawings for this invention for further clarification.

[0017] figure 1 Shown: an advanced treatment and recovery device for raffinate wastewater from nickel and cobalt production enterprises includes first and second adsorption stirring tanks 1 and 2, ammonia solution batching tank 7, washing water tank 8, filter pump 9 and filter device 10, the first The first and second adsorption stirring tanks are equipped with stirrers 12, the first and second adsorption stirring tanks are connected through the catheter 6 with the liquid guide control valve 11, and the first adsorption stirring tank 1 is provided with a sewage liquid inlet 4 and the solid feed inlet 5, the steam heating pipe 3 is connected to the first adsorption stirring tank 1, and the second adsorption stirring tank 2 is connected to the filter device 10 through the filter pump 9; the ammonia solution batching tank 7 and the washing water tank 8 are respectivel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com