Gas-assisted molding glass fiber reinforced nylon 6 engineering plastic and preparation method thereof

A technology of engineering plastics and gas-assisted molding, which is applied in the field of materials, can solve problems such as difficult bonding, rough product surface, and poor fluidity, and achieve the effects of improving interface bonding, increasing mechanical properties, and overcoming anisotropy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

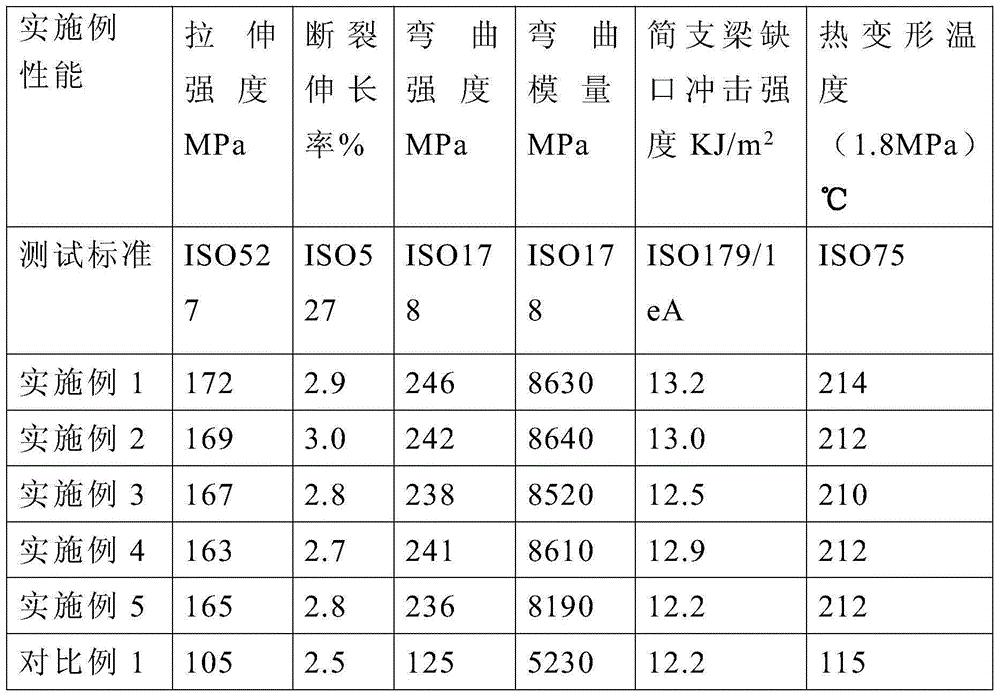

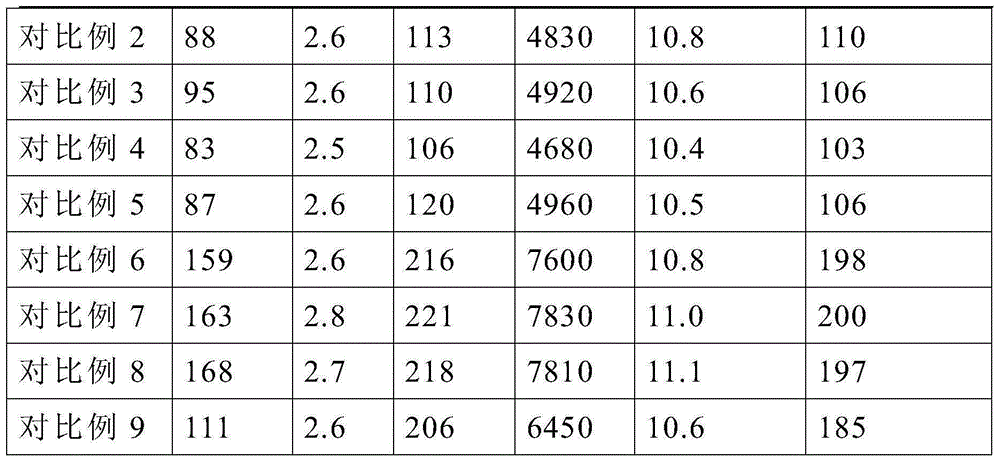

Examples

Embodiment 1

[0029] Raw materials are taken by weighing percentages as follows: nylon 6 resin 55wt%; alkali-free glass fiber 20wt%; carbon fiber 8wt% after surface treatment; aramid fiber 8wt%; compatibilizer maleic anhydride grafted polypropylene 5wt%; 3.2wt% of maleic anhydride grafted acrylate and styrene copolymer; 10100.8wt% of antioxidant; wherein, the viscosity of the nylon 6 resin is 2.2-2.7, and the surface of the alkali-free glass fiber Coated with a graphene oxide coating with a thickness of 0.3-0.8 μm, the alkali-free glass fiber is chopped glass fiber, the length of the chopped glass fiber is 1.5-4.5 mm, and the diameter is 9-14 μm. The aramid fiber is chopped aramid fiber, the length of the chopped aramid fiber is 1-4mm, the melt index of the maleic anhydride grafted polypropylene is ≤50g / 10min, and the grafting rate is 0.5-1.5%.

[0030] Mix the weighed raw material nylon 6 resin, compatibilizer, flow modifier, and antioxidant in a high-speed mixer at high speed, and then me...

Embodiment 2

[0032] Raw materials are taken by weight percentage as follows: nylon 6 resin 60wt%; alkali-free glass fiber 20wt%; carbon fiber 5wt% after surface treatment; aramid fiber 5wt%; compatibilizer maleic anhydride grafted polyethylene 7wt%; 2.4wt% of maleic anhydride grafted acrylate and styrene copolymer; 10760.3wt% of antioxidant, 1680.3wt% of antioxidant; wherein, the viscosity of the nylon 6 resin is 2.2-2.7, and the The surface of the alkali-free glass fiber is coated with a graphene oxide coating with a thickness of 0.3-0.8 μm, and the alkali-free glass fiber is chopped glass fiber, the length of the chopped glass fiber is 1.5-4.5mm, and the diameter is 9-14 μm, the aramid fibers are chopped aramid fibers, and the length of the chopped aramid fibers is 1-4mm.

[0033] Mix the weighed raw material nylon 6 resin, compatibilizer, flow modifier, and antioxidant in a high-speed mixer at high speed, and then melt it through a twin-screw extruder. Alkali glass fiber, carbon fiber ...

Embodiment 3

[0035] Raw materials are taken by weight percentage as follows: 52wt% of nylon 6 resin; 30wt% of alkali-free glass fiber; 6wt% of carbon fiber after surface treatment; 3wt% of aramid fiber; 4wt% of compatibilizer maleic anhydride grafted polypropylene; 4.3wt% of maleic anhydride grafted acrylate and styrene copolymer; 10100.4wt% of antioxidant, 1680.3wt% of antioxidant; wherein, the viscosity of the nylon 6 resin is 2.2-2.7, and the The surface of the alkali-free glass fiber is coated with a graphene oxide coating with a thickness of 0.3-0.8 μm, and the alkali-free glass fiber is chopped glass fiber, the length of the chopped glass fiber is 1.5-4.5mm, and the diameter is 9-14 μm, the aramid fibers are chopped aramid fibers, the length of the chopped aramid fibers is 1-4mm, the melt index of the maleic anhydride grafted polypropylene is less than or equal to 50g / 10min, and the grafting rate is 0.5-1.5%.

[0036] Mix the weighed raw material nylon 6 resin, compatibilizer, flow ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com