Tungstate upconversion luminescence temperature sensitive material doped with rare-earth elements Er and Yb and preparation method thereof

A technology of rare earth elements and sensitive materials, applied in luminescent materials, chemical instruments and methods, tungsten compounds, etc., can solve the problems of unreported temperature sensing performance, and achieve the effects of easy industrial promotion, easy preparation, and stable process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

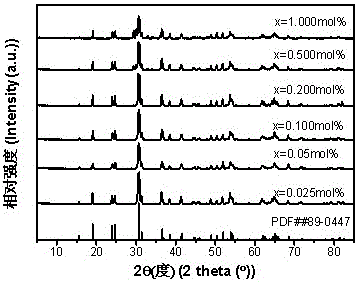

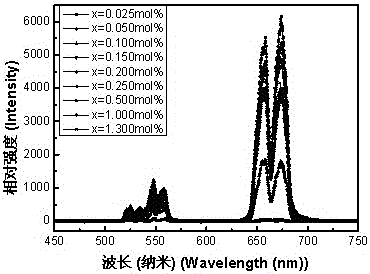

[0033] Preparation of ZnWO by Solid Phase Method 4 : Er0.025mol%, Yb0.25mol% ceramic material, the preparation method is as follows:

[0034] Using high-purity zinc oxide (ZnO, 99.8%), erbium oxide powder (Er 2 o 3 , 99.9%), ytterbium oxide powder (Yb 2 o 3 , 99.9%), tungsten trioxide powder (WO 3 , 99.9%) as the raw material, weigh the raw material according to the stoichiometric ratio, put it into the agate mortar, mix it evenly with alcohol as the solvent, dry the powder after the alcohol is ground, put the obtained powder into the corundum boat and pre-fire it in the air , the calcining temperature is 750°C, the heating rate is 3°C / min, the heat preservation is 5 hours, and the calcining powder is obtained by natural cooling. Then put the calcined powder into the agate mortar and add alcohol to grind again for 2 hours and dry. Add an appropriate amount of polyvinyl alcohol (PVA) with a concentration of 5% as a binder, fully stir, granulate, and pass through a 160-mes...

Embodiment 2

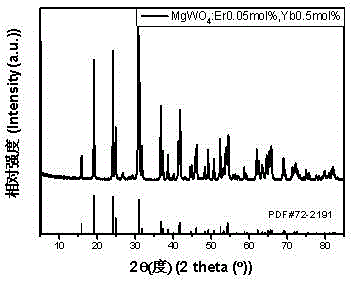

[0036] Preparation of ZnWO by Solid Phase Method 4 : Er0.05mol%, Yb0.5mol% ceramic material, the preparation method is as follows:

[0037] Using high-purity zinc oxide (ZnO, 99.8%), erbium oxide powder (Er 2 o 3 , 99.9%), ytterbium oxide powder (Yb 2 o 3 , 99.9%), tungsten trioxide powder (WO 3 , 99.9%) as the raw material, weigh the raw material according to the stoichiometric ratio, put it into the agate mortar, mix it evenly with alcohol as the solvent, dry the powder after the alcohol is ground, put the obtained powder into the corundum boat and pre-fire it in the air , the calcining temperature is 750°C, the heating rate is 3°C / min, the heat preservation is 5 hours, and the calcining powder is obtained by natural cooling. Then put the calcined powder into the agate mortar and add alcohol to grind again for 2 hours and dry. Add an appropriate amount of polyvinyl alcohol (PVA) with a concentration of 5% as a binder, fully stir, granulate, and pass through a 160-mesh ...

Embodiment 3

[0039] Preparation of ZnWO by Solid Phase Method 4 : Er0.1mol%, Yb0.5mol% ceramic material, the preparation method is as follows:

[0040] Using high-purity zinc oxide (ZnO, 99.8%), erbium oxide powder (Er 2 o 3 , 99.9%), ytterbium oxide powder (Yb 2 o 3 , 99.9%), tungsten trioxide powder (WO 3 , 99.9%) as the raw material, weigh the raw material according to the stoichiometric ratio, put it into the agate mortar, mix it evenly with alcohol as the solvent, dry the powder after the alcohol is ground, put the obtained powder into the corundum boat and pre-fire it in the air , the calcining temperature is 750°C, the heating rate is 3°C / min, the heat preservation is 5 hours, and the calcining powder is obtained by natural cooling. Then put the calcined powder into the agate mortar and add alcohol to grind again for 2 hours and dry. Add an appropriate amount of polyvinyl alcohol (PVA) with a concentration of 5% as a binder, fully stir, granulate, and pass through a 160-mesh s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com