Source reduction complete technology method for heavy metal water pollutants in zinc electrolytic process

A technology for water pollutants and heavy metals, applied in the electrolysis process, electrolysis components, photography technology, etc., can solve the problems of large amount of heavy metal wastewater, low electrolysis efficiency, and large labor load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

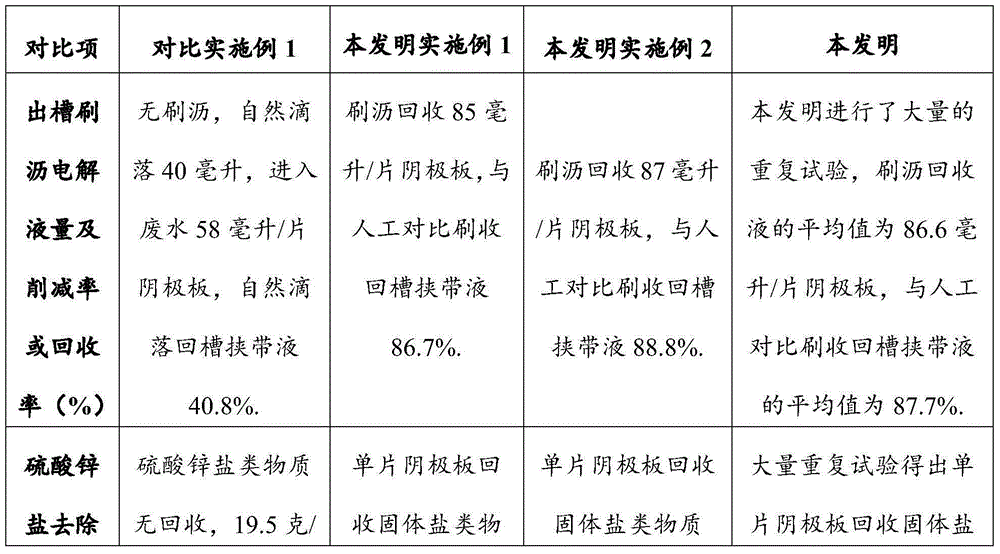

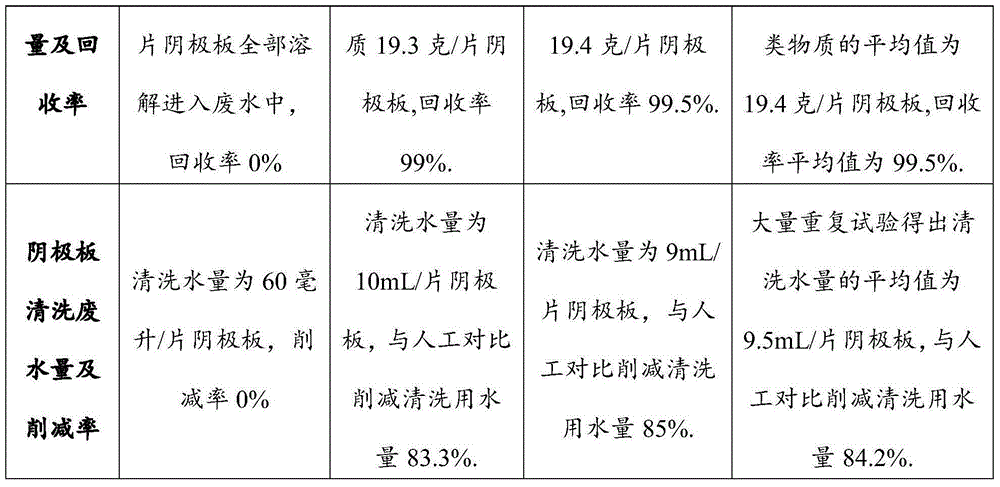

Embodiment 1

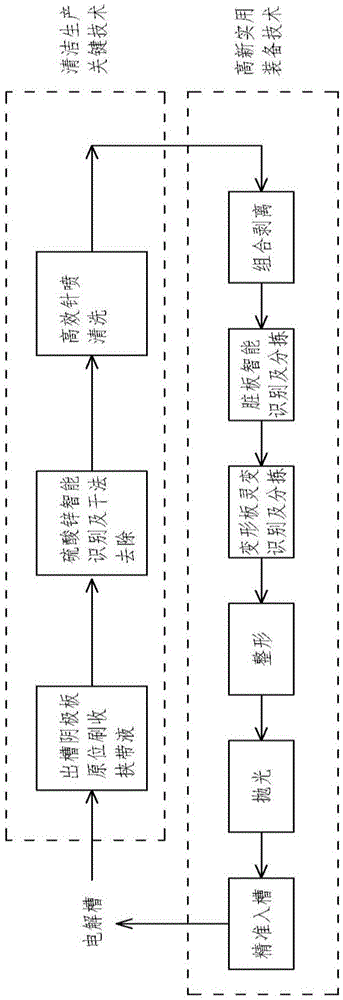

[0031] Such as figure 1 shown, including the following steps:

[0032] (1) Liquid phase source reduction: The 600 mm × 800 mm cathode plate electrolyzed in a 24-hour cycle is lifted from the electrolyte. During the process of lifting the cathode plate from the electrolyte, brushes are used to tightly close the zinc skin surface attached to the cathode plate. fit brush;

[0033] There is a 5cm-thick thin metal layer deposited on the surface of the cathode plate, which is called the zinc skin. Affected by other factors during the electrolysis process, the metallic zinc deposited on the surface of the zinc skin is uneven and rough, resulting in local high or low-lying parts. , during the electrolysis process of the cathode plate, a large amount of entrained liquid on the surface of the cathode plate is the initial liquid phase source of heavy metals in the cleaning wastewater of the electrolysis workshop. A certain thickness of zinc skin is deposited on both sides of the cathode...

Embodiment 2

[0040] Such as figure 1 shown, including the following steps:

[0041] (1) Liquid phase source reduction: The 650 mm × 800 mm cathode plate electrolyzed in a 24-hour cycle is lifted from the electrolyte, and the zinc skin surface attached to the cathode plate is tightly pressed with a brush during the process of lifting the cathode plate from the electrolyte. fit brush;

[0042] There is a 4cm-thick thin metal layer deposited on the surface of the cathode plate, which is called zinc skin. Affected by other factors during the electrolysis process, the metal zinc deposited on the surface of the zinc skin is uneven and rough, resulting in local high or low-lying parts. , during the electrolysis process of the cathode plate, a large amount of entrained liquid on the surface of the cathode plate is the initial liquid phase source of heavy metals in the cleaning wastewater of the electrolysis workshop. A certain thickness of zinc skin is deposited on both sides of the cathode plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com