Method for detecting quality of airplane covering-riveting assembling surface

A technology for aircraft skin and surface quality, which is applied in measurement devices, optical devices, instruments, etc., to achieve the effects of good reliability, multiple measurement functions, and improved surface quality and production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further elaborated below in conjunction with the accompanying drawings.

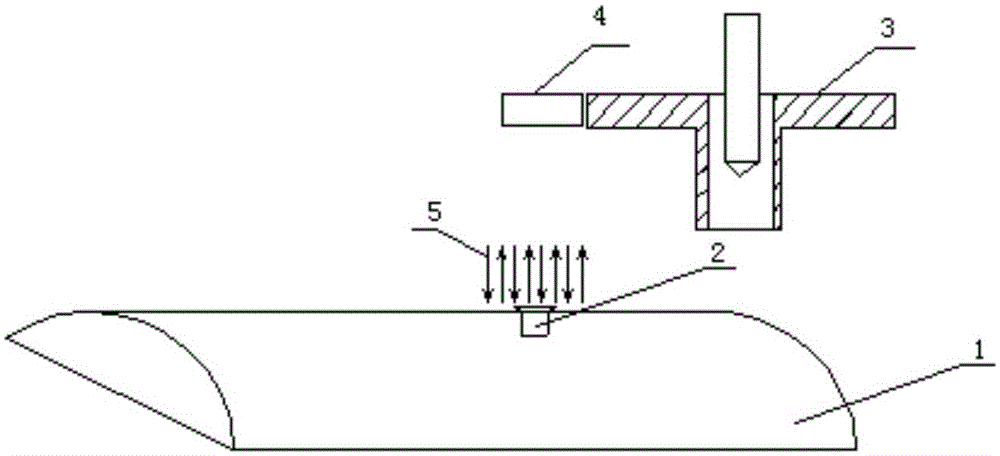

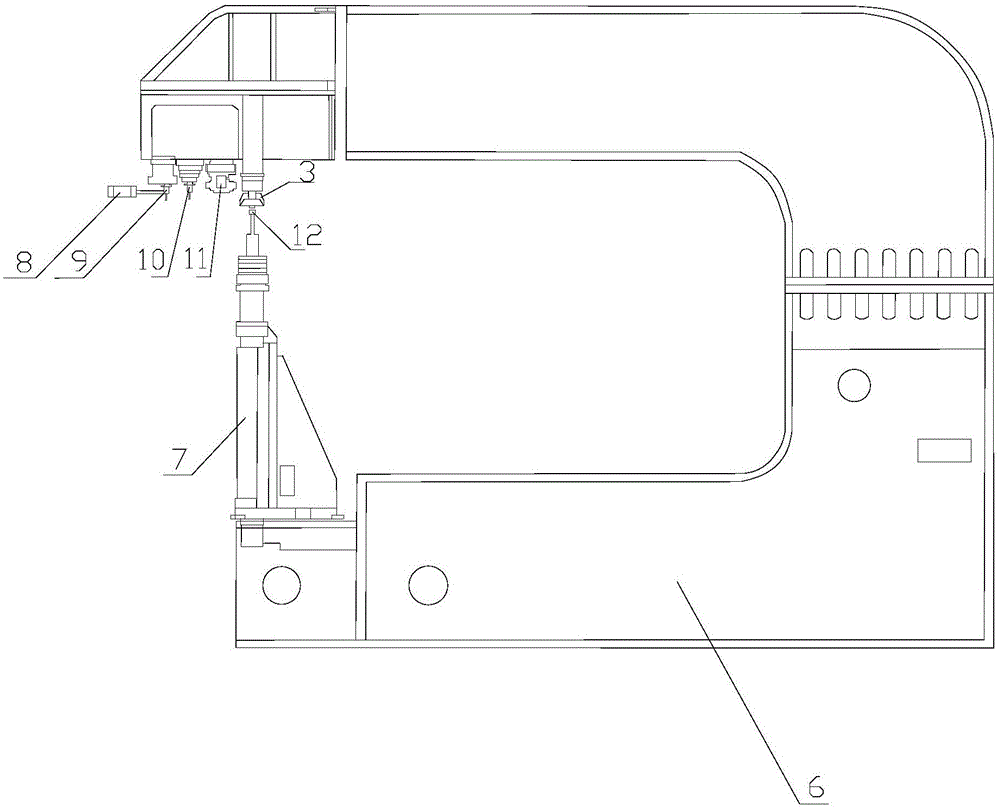

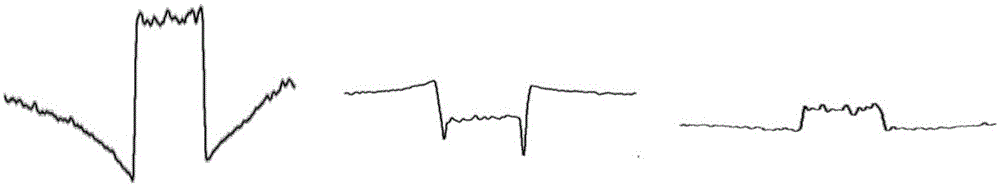

[0024] Such as Figure 1-2 The method for detecting the surface quality of aircraft skin riveting assembly shown includes: a, first installing the 2D displacement sensor 4 on the side of the upper pressure foot 3 in the drill riveting system; b, when the drill riveting system rivets the rivet 2 to the After the aircraft skin 1 is attached, the drilling and riveting system moves the aircraft skin 1 and the rivet 2 to the right below the 2D displacement sensor 4. The drilling and riveting system sends measurement instructions to the measurement system. Displacement sensor 4 issues a data collection instruction, and 2D displacement sensor 4 sends out a measurement beam 5 to irradiate the rivet 2 and aircraft skin 1 after receiving the data collection instruction, and the measurement beam 5 returns to the 2D displacement sensor 4 after diffuse reflection to form the first...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com