Active optical cable connector assembly

A technology for optical cable connectors and electrical connectors, which is applied in the field of active optical cable connector components, and can solve complex and cumbersome installation and debugging of optical cable connectors and optical cables, weak anti-vibration and shock resistance of optical modules, and lower transmission performance indicators of optical modules and other problems, to achieve the effect of simple and convenient installation and debugging, light weight and strong bending resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The active optical cable connector assembly of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments:

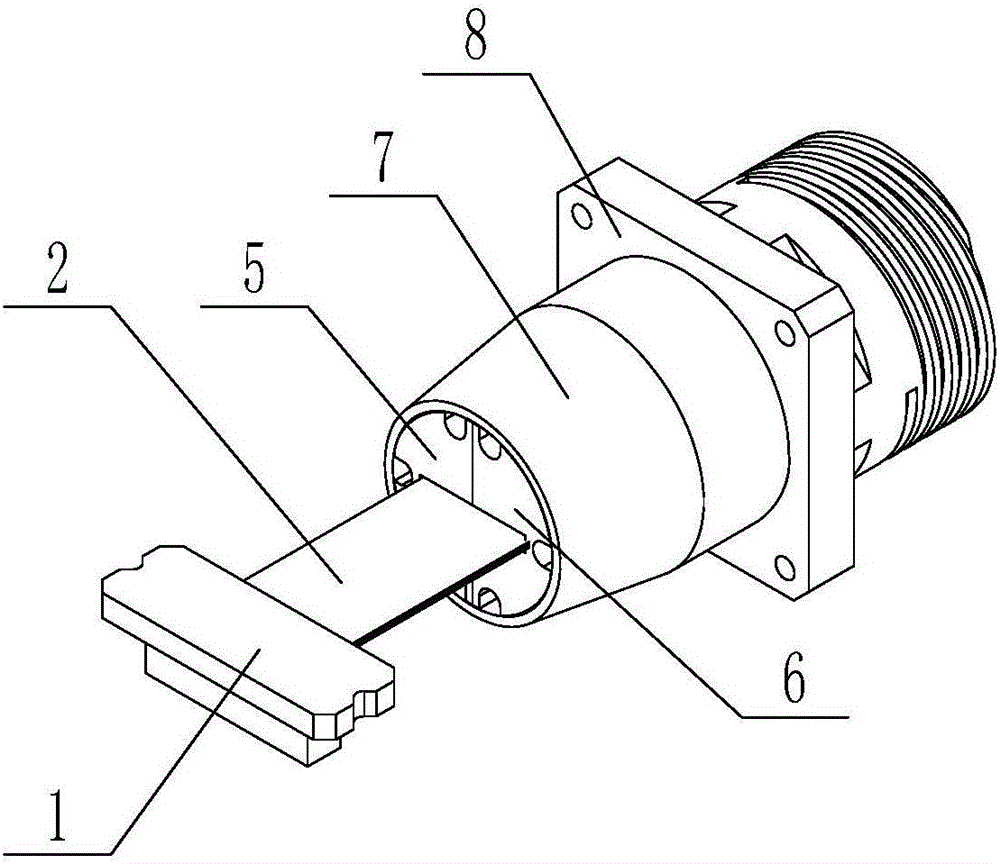

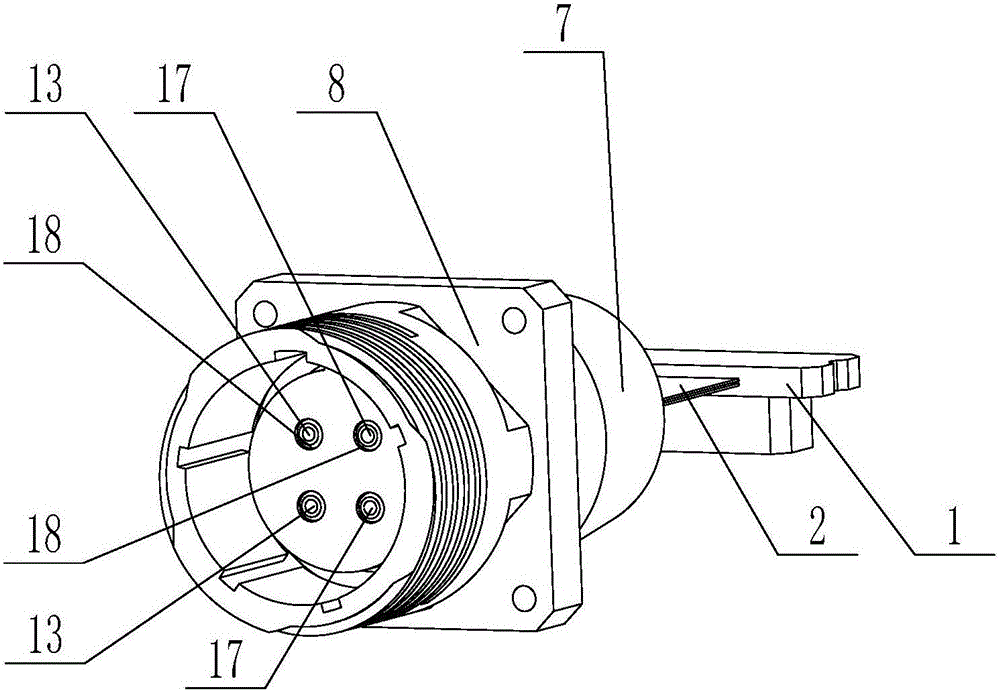

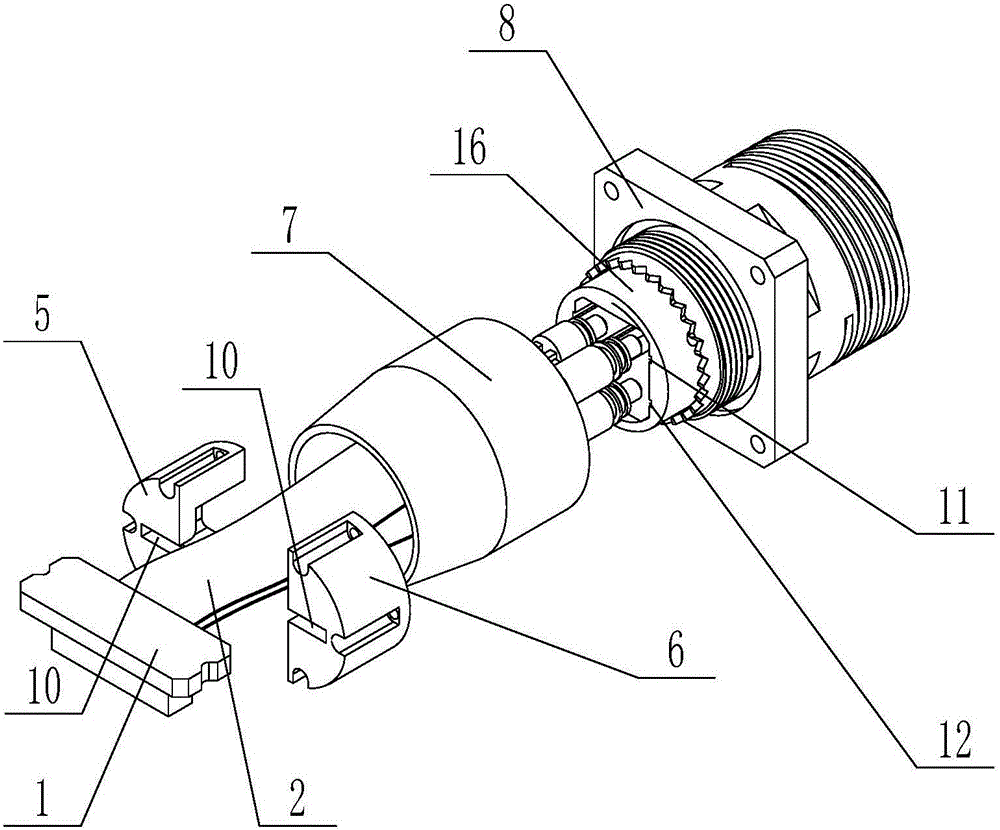

[0027] like figure 1 , figure 2 , image 3 , Figure 4 and Figure 5 As shown, the active optical cable connector assembly of the present invention includes a high-speed electrical connector 1, a flexible circuit board 2, an upper layer optical module 3, a lower layer optical module 4, a left half tail ring 5, a right half tail ring 6, and a boot 7 , the connector socket shell 8 and the plug 9 . Both the upper-layer optical module 3 and the lower-layer optical module 4 are electrically connected to the high-speed electrical connector 1 through a flexible circuit board 2 . The left half tail retaining ring 5 and the right half tail retaining ring 6 are combined and located in the boot 7, the left half tail retaining ring 5 and the right half tail retaining ring 6 are provided with a card slot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com