Control modes for PWR (Pressurized Water Reactor) core of nuclear power plant

A control mode, a technology for nuclear power plants, which is applied in nuclear power generation, plant parameter adjustment, and greenhouse gas reduction. generation, reduced wastewater treatment costs, and extended load-following capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

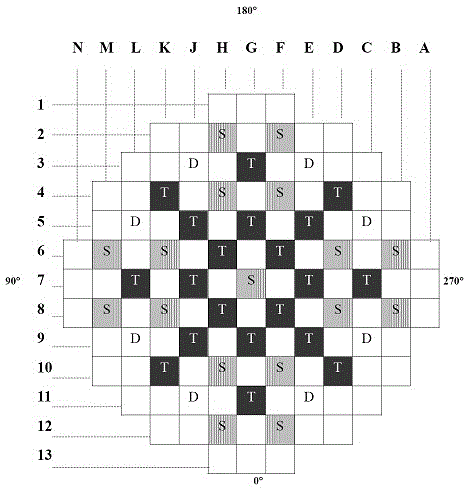

[0036]This embodiment is aimed at a pressurized water reactor core of a 650,000-kilowatt nuclear power plant, and the core is composed of 121 fuel assemblies. The core uses 45 bundles of control rods, of which 33 bundles are black body control rods and 12 bundles are gray body control rods. The control rod group includes a T rod group and a D rod group. The T rod group is required to meet the specified number of overlapping steps and sequence when moving, and is used to control the core reactivity / coolant average temperature; the D rod group is used for the axial direction of the core. Power distribution control. The shutdown rod group is S rod group, which is used to ensure that the reactor has sufficient shutdown margin at any power level. figure 1 A schematic diagram of a typical control rod arrangement is given, and the arrangement of fuel assemblies containing T rod groups, D rod groups, or S rod groups in the whole core follows 1 / 4 rotational symmetry, taking the lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com