Enhancement mode HEMT (high electron mobility transistor) device

An enhanced and device technology, applied in semiconductor devices, electrical components, circuits, etc., can solve problems such as gate leakage, barrier layer material damage, and difficulty in controlling the distribution of fluorine ions, and achieve the effect of facilitating control and reducing the effective area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

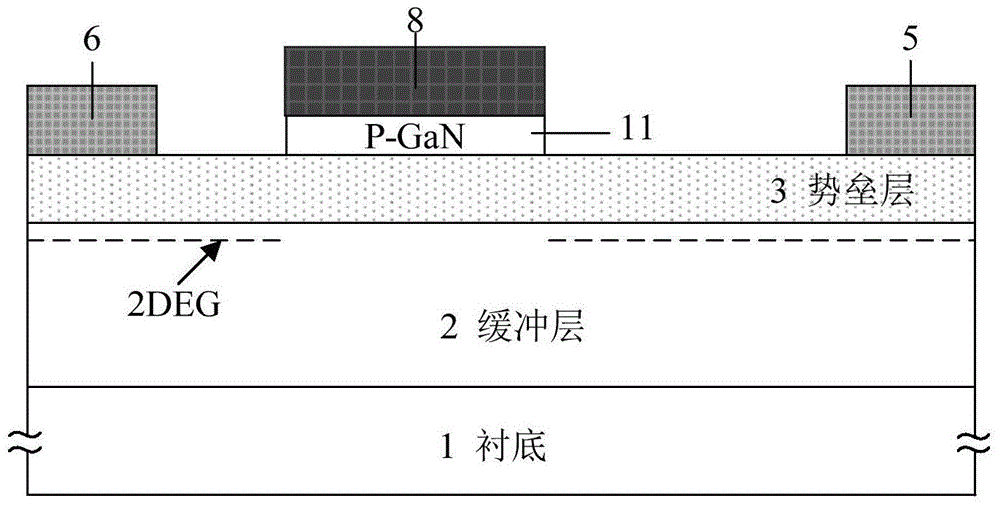

[0037] like Figure 5 As shown, it includes a substrate 1, a buffer layer 2 located on the upper layer of the substrate 1 and a barrier layer 3 located on the upper layer of the buffer layer 2, and the contact surface between the buffer layer 2 and the barrier layer 3 is formed with a two-dimensional electron gas (2DEG ) the first heterojunction of the channel; one end of the upper surface of the barrier layer 3 has a drain electrode 5 that forms ohmic contact with the barrier layer 3; it is characterized in that the upper surface of the barrier layer 3 has a A reversely polarized reverse polarization semiconductor layer 4, the contact surface of the reverse polarization semiconductor layer 4 and the barrier layer 3 forms a second heterojunction with two-dimensional hole gas (2DHG); the reverse polarization One end of the upper surface of the semiconductor layer 4 away from the leakage current 5 has a source electrode 6, and the connection interface between the source electrod...

Embodiment 2

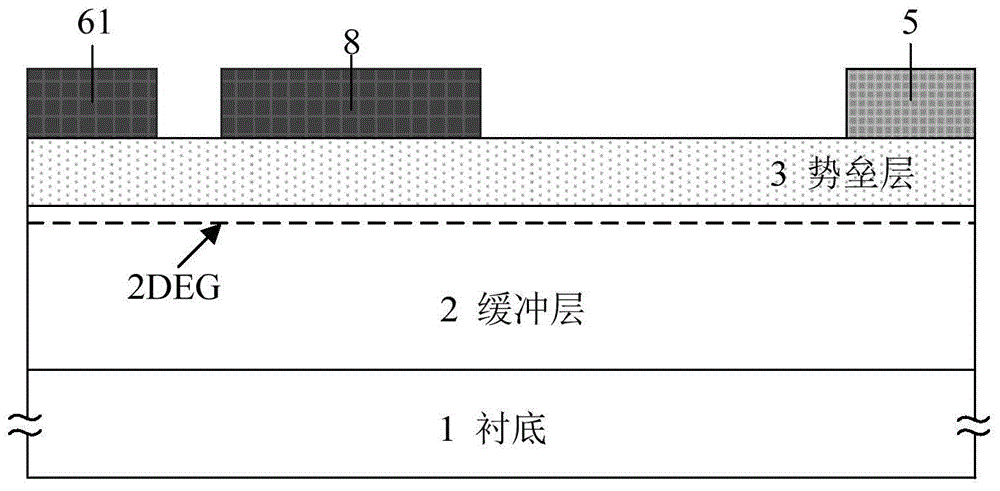

[0040] This example is a polarized superjunction tunneling enhanced HEMT device that uses ion injection to block holes. Compared with Example 1, the device of this example uses a high concentration of N between the reverse polarization layer 4 and the drain electrode 5. The hole blocking region 9 is realized by ion implantation, avoiding the formation of a hole conduction channel between the source and the drain; at the same time, a P-type doped region is formed in a part of the reverse polarized layer between the source and the drain to prevent electrons from Leakage path from source to drain, other structures are the same as in Example 1, such as Image 6 shown. The NP junction formed between the drain electrode and the source electrode also plays the role of withstand voltage when the device is in the blocking state. The isolation methods in conventional HEMT devices mainly include trench isolation and ion implantation isolation. Compared with trench isolation, ion implant...

Embodiment 3

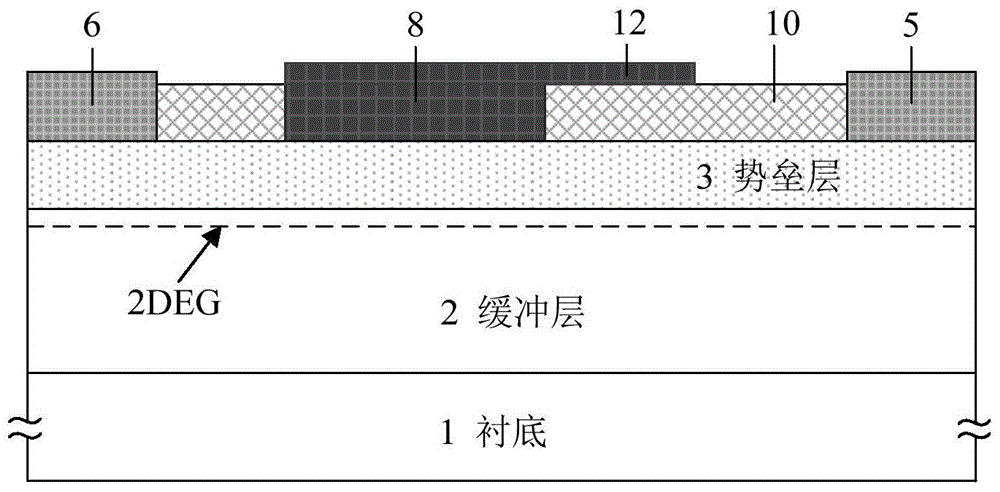

[0042] This example is an enhancement mode HEMT device in which the part of the reverse polarized layer located under the source electrode adopts N-type doping. type doping, other structures are the same as in Example 1, such as Figure 7 shown. On the one hand, the N-type doping part under the source electrode can better form ohmic contact between the source metal and the reverse polarized layer; on the other hand, the N-type doping modulates the 2DHG concentration, thereby regulating the threshold voltage; Step doping or linear doping can be performed on other parts of the polarization layer to further optimize the lateral electric field distribution in the drift region of the device and improve the withstand voltage.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com