Table tennis ball and table tennis ball-use thermoplastic resin composition

A technology of thermoplastic resin and table tennis, applied in applications, rackets, balls, etc., can solve problems such as low speed, increased mistakes, and changes in playing sound, and achieve an excellent balance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

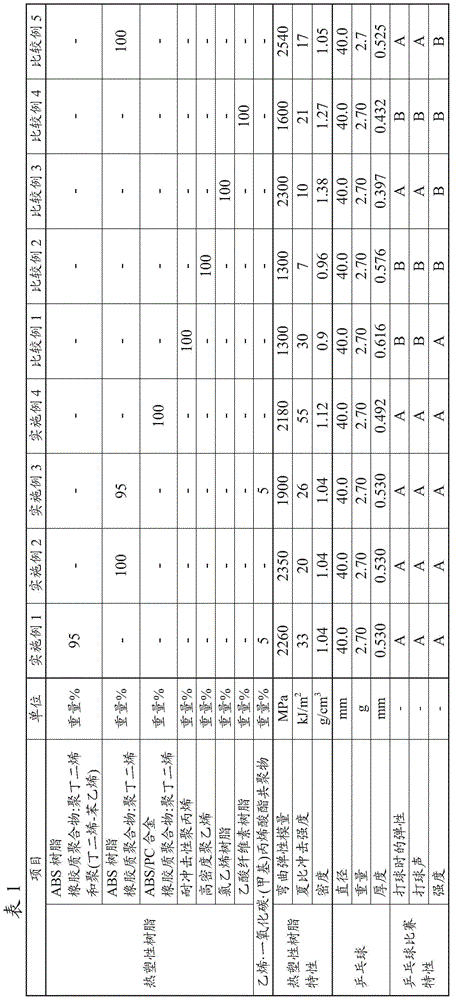

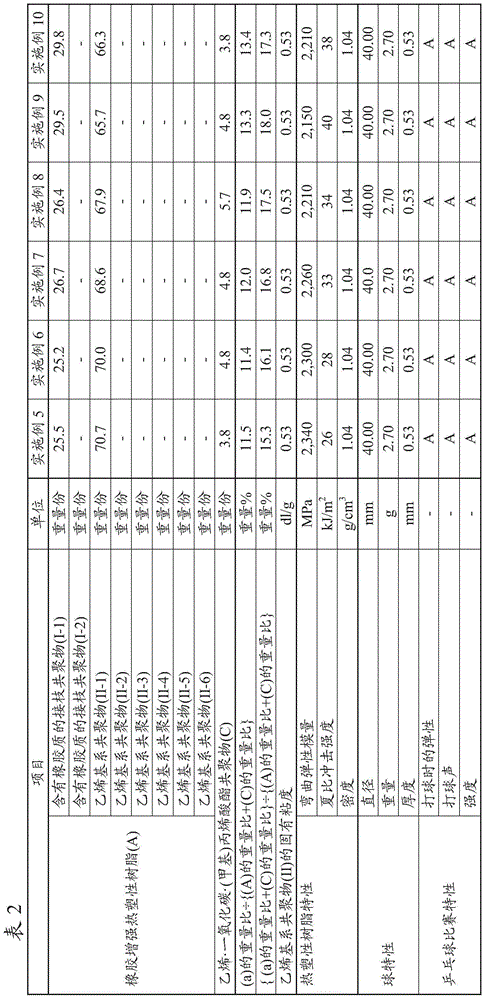

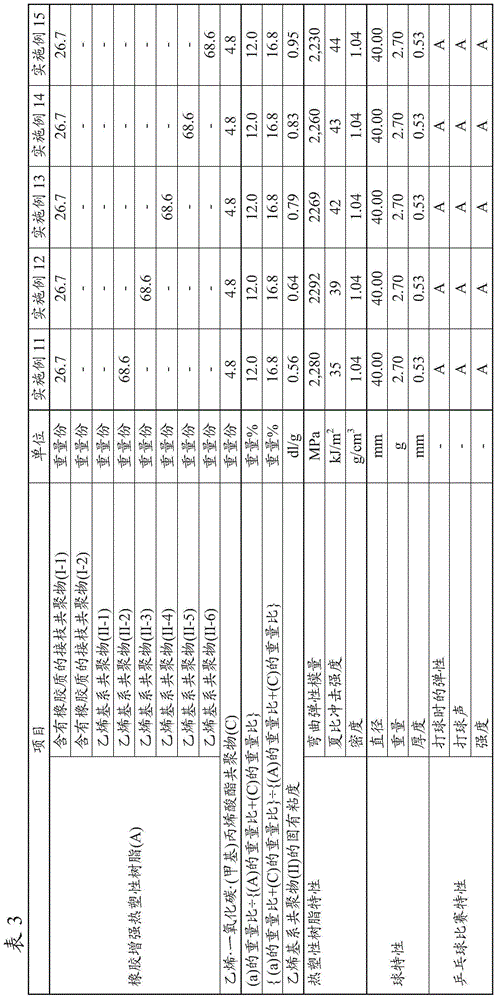

[0103] In order to describe the present invention more specifically, examples and comparative examples are given below, but these examples do not limit the present invention in any way. The table tennis balls shown in Examples and Comparative Examples are made by joining hollow hemispherical molded products obtained by injection molding by a method suitable for each raw material and complying with the standards stipulated in ITTF Technical Standard T3. size ping pong ball. In addition, here, unless otherwise specified, "%" means weight%, and "part" means a weight part.

[0104] First, raw materials, evaluation methods in Examples and Comparative Examples will be described.

[0105] (1) Average particle diameter of the rubbery polymer (a)

[0106] Using the sodium alginate method described in "RubberAgeVol.88p.484-490 (1960), byE.Schmidt, P.H.Biddison", that is, using the different particle sizes of polybutadiene that is creamed according to the concentration of sodium algina...

reference example 1

[0121] [Reference Example 1] Graft Copolymer Containing Rubber (I-1)

[0122] 150 parts by weight of pure water, 0.5 parts by weight of glucose, 0.5 parts by weight of sodium pyrophosphate, 0.005 parts by weight of ferrous sulfate, and 45 parts by weight (in terms of solid content) were put into the nitrogen-substituted reactor, and the average particle diameter was 1.00 μm. The poly(butadiene-styrene) latex (weight ratio of styrene and butadiene is 25 / 75), while stirring, the temperature in the reactor was raised to 65°C. The time when the internal temperature reached 65° C. was regarded as the start of polymerization, and 39 parts by weight of styrene, 16 parts by weight of acrylonitrile, and 0.2 parts by weight of a chain transfer agent mixture of t-dodecyl mercaptan were continuously added over 4 hours. Simultaneously, an aqueous solution containing 0.2 parts by weight of cumene hydroperoxide and potassium oleate, a polymerization initiator, was continuously added over 7 h...

reference example 2

[0123] [Reference Example 2] Graft Copolymer (I-2) Containing Rubber

[0124] 150 parts by weight of pure water, 0.5 parts by weight of glucose, 0.5 parts by weight of sodium pyrophosphate, 0.005 parts by weight of ferrous sulfate, and 60 parts by weight (in terms of solid content) of the average particle diameter of 0.35 μm were put into the nitrogen-substituted reactor. The polybutadiene latex was stirred, and the temperature in the reactor was raised to 65°C. The polymerization started when the internal temperature reached 65° C., and 28 parts by weight of styrene, 12 parts by weight of acrylonitrile and 0.2 parts by weight of a chain transfer agent t-dodecyl mercaptan mixture were continuously added over 4 hours. Simultaneously, an aqueous solution containing 0.2 parts by weight of cumene hydroperoxide and potassium oleate, a polymerization initiator, was continuously added over 7 hours to complete the reaction. Add 1 part by weight of 2,2'-methylene bis(4-methyl-6-tert-b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Flexural modulus of elasticity | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com