High-aroma instant tea and preparation method thereof

An instant tea and fragrant tea technology, applied in the direction of tea extraction, etc., can solve the problems of increased equipment investment and production cost, insufficient extraction of tea aroma components, industrial application restrictions, etc., and achieves reduction of equipment investment and production cost, considerable Profit margins and economic efficiency, investment and production cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] Preparation method of high fragrance instant tea

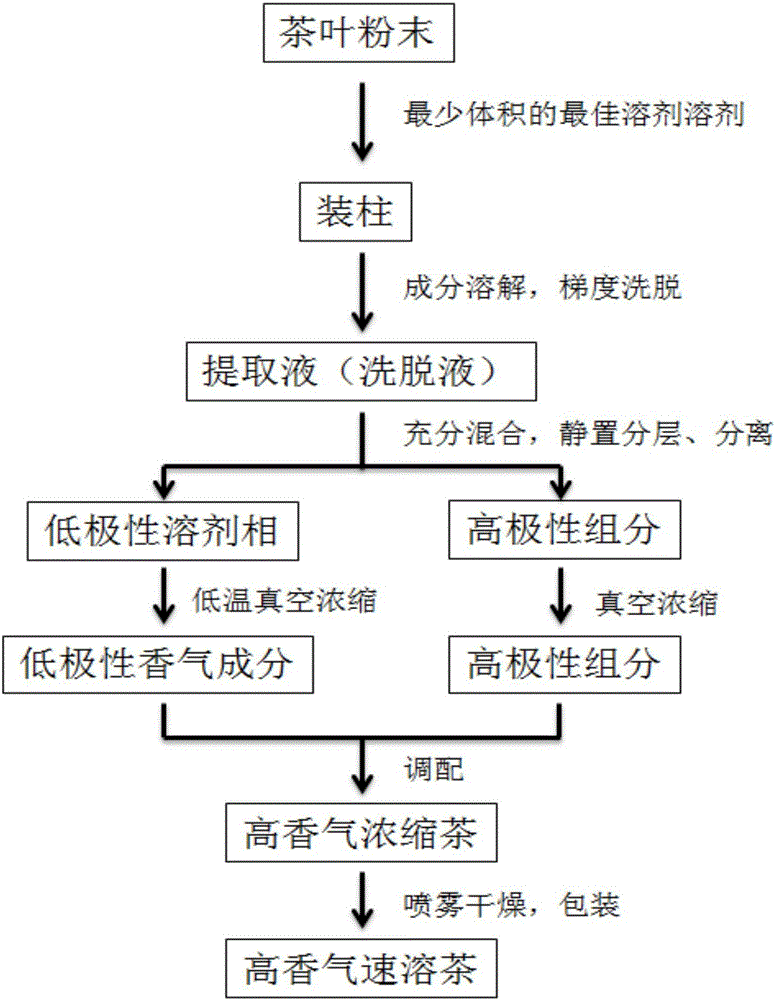

[0041] refer to figure 1 , the preparation method of high fragrance instant tea of the present invention comprises the following steps:

[0042] (1) Tea sample processing.

[0043] Crush the tea leaves with a pulverizer, pass through a 20-60 mesh sieve, and use them directly for extraction, or bake them in an oven at 65°C (or 50-80°C) for about 4 hours, and store them in a sealed and dry place for extraction.

[0044] (2) Dissolution of tea soluble matter.

[0045] Accurately weigh 2 kg of tea powder in step (1), and use 4 liters of ether alcohol solvent (petroleum ether: 95% ethanol = 8:2) to pack the column evenly into a vertical column according to the method of column chromatography wet method. In the column, the packing height is 5-10 times of the diameter of the chromatography column. Stand still for 3 hours after column packing, so that the soluble components in the tea powder are fully dissolved.

[0046]...

Embodiment 2

[0058] Experimental procedure for optimal extraction conditions

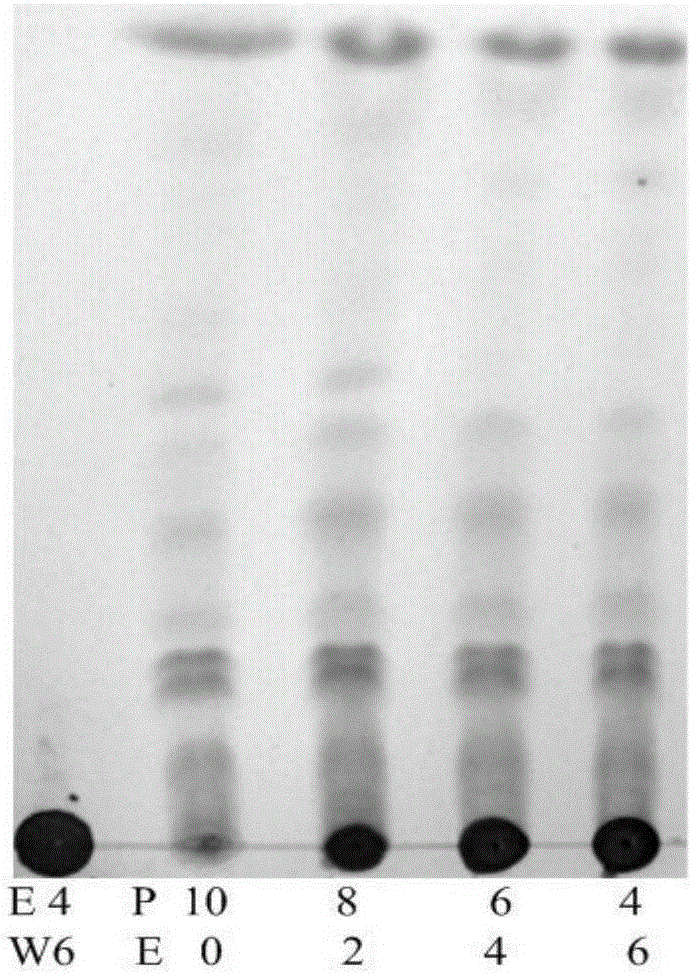

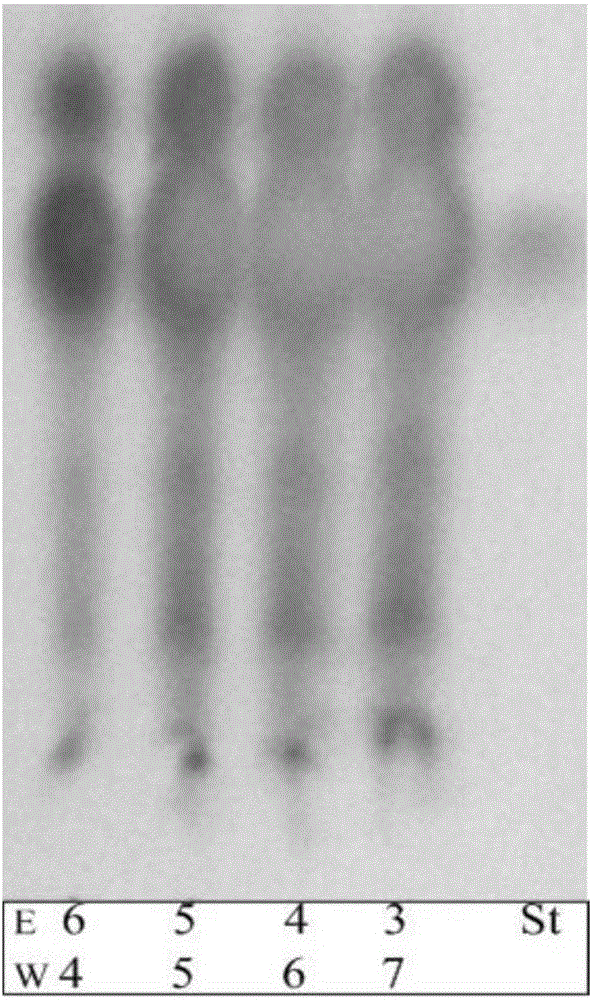

[0059] refer to figure 2 with image 3 , the components of the first extract and the second extract and the ratio of each component play a key role in the separation of low polar aroma components and medium and high polar components.

[0060] Such as figure 2 As shown, the alcohol-water solvent composed of ethanol (represented by "E" in the figure) and water (represented by "W" in the figure) dissolves the ingredients in the tea powder, but it can be seen through thin-layer chromatography analysis that the above-mentioned The alcohol-water system meter failed to spread the low-polar components in the tea powder on the thin-layer plate, indicating that the alcohol-water solvent failed to dissolve the low-polar components in the tea powder. However, after the ether-based solvent containing only petroleum ether (indicated by "P" in the figure) dissolves the components in the tea powder, the thin-layer chromato...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com