A kind of propylene glycol monostearate and its industrial production method and application

A technology of propylene glycol monostearate and monostearate, which is applied in the directions of application, carboxylate preparation, chemical apparatus and method, etc., to achieve the effects of improving cake quality, increasing cake volume, and easily controlling conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

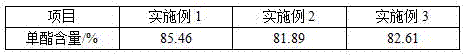

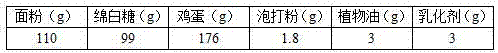

Examples

Embodiment 1

[0022] Embodiment 1, propylene glycol monostearate industrial production method of the present invention

[0023] S1, 91.3kg of 1,2-propanediol and 113.8kg of stearic acid are heated and melted respectively and then filtered;

[0024] S2. Pump 1,2-propylene glycol into the reaction kettle, add 0.10% sodium carbonate by weight of 1,2-propylene glycol, stir and mix for 30 minutes, then pump stearic acid into the reaction kettle, control the reaction temperature to 175°C, and the vacuum degree to be 0.07MPa, carry out esterification reaction for 3h;

[0025] S3, the esterification reaction is completed, the material is discharged into the neutralization tank, and 0.15% phosphoric acid by weight of 1,2-propylene glycol is added, and the neutralization reaction is carried out at 145°C for 0.8h;

[0026] S4, neutralization reaction finishes and obtains crude ester, discharges to storage tank and stands still;

[0027] S5, transfer the crude ester to the distiller for four-stage di...

Embodiment 2

[0028] Embodiment 2, propylene glycol monostearate industrial production method of the present invention

[0029] S1, 60.9kg of 1,2-propanediol and 113.8kg of stearic acid were heated and melted respectively and then filtered;

[0030] S2. Pump 1,2-propanediol into the reactor, add 0.30% sodium bicarbonate by weight of 1,2-propylene glycol, stir and mix for 25 minutes, then pump stearic acid into the reactor, control the reaction temperature to 160°C, vacuum to 0.08MPa, carry out the esterification reaction for 4h;

[0031] S3, the esterification reaction is completed, the material is discharged into the neutralization tank, and 0.35% phosphoric acid by weight of 1,2-propylene glycol is added, and the neutralization reaction is carried out at 140 ° C for 1 hour;

[0032] S4, neutralization reaction finishes and obtains crude ester, discharges to storage tank and stands still;

[0033] S5, transfer the crude ester to a distiller for four-stage distillation, wherein the condit...

Embodiment 3

[0034] Embodiment 3, propylene glycol monostearate industrial production method of the present invention

[0035] S1, 121.7kg of 1,2-propanediol and 113.8kg of stearic acid are heated and melted respectively and then filtered;

[0036] S2. Pump 1,2-propylene glycol into the reaction kettle, add 0.20% sodium hydroxide by weight of 1,2-propylene glycol, stir and mix for 35 minutes, then pump stearic acid into the reaction kettle, control the reaction temperature to 180°C, vacuum 0.06MPa, carry out the esterification reaction for 2h;

[0037] S3, the esterification reaction is completed, the material is discharged into the neutralization tank, and 0.25% phosphoric acid by weight of 1,2-propylene glycol is added, and the neutralization reaction is carried out at 150°C for 0.5h;

[0038] S4, neutralization reaction finishes and obtains crude ester, discharges to storage tank and stands still;

[0039] S5, transfer the crude ester to the distiller for four-stage distillation, wher...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com