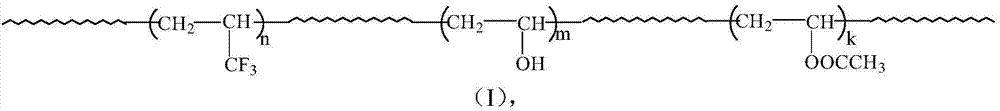

A kind of ternary fluorine-containing resin and its preparation method and application

A technology of fluorine-containing resin and trifluoropropylene, which is applied in chemical instruments and methods, textiles and papermaking, non-woven fabrics, etc., can solve the problems of hydrophilic modification instability, etc., and achieve improved water flux and low branching degree , the effect of less chain transfer

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

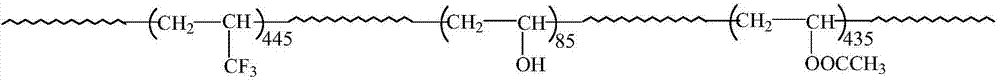

Embodiment 1

[0034] Embodiment 1, preparation of ternary fluororesin

[0035] Vacuumize the 1L reactor to remove water and air, pass carbon dioxide and then vacuumize, repeat three times; introduce 43.0g of pre-cooled vinyl acetate into the vacuumized reactor, and then press 48.0g of trifluoropropene into the vacuumized reactor monomer, heating the reactor to 35°C; then carbon dioxide was pressed into the reactor with a high-pressure plunger pump, and after the pressure reached 36MPa, 3.0g of 4wt% (CF 3 CF 2 (CF 2 OCF (CF 3 )) 2 COO) 2 The 1,1,2-trifluorotrichloroethane solution was added to the reactor to initiate polymerization; after 8 hours of polymerization, the valve was slowly opened to recover carbon dioxide and remaining monomers, and fresh carbon dioxide was repeatedly filled to extract the copolymer, and finally collected As a product, 59.3 g of a binary copolymer of vinyl acetate and trifluoropropylene was obtained.

[0036] Mix 10.0g of vinyl acetate and trifluoropropyle...

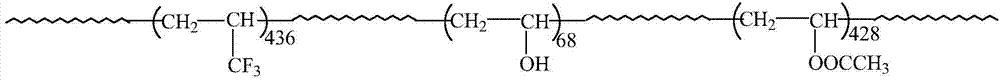

Embodiment 2

[0040] Embodiment 2, the preparation of ternary fluororesin

[0041] Vacuumize the 1L reactor to remove water and air, pass carbon dioxide and then vacuumize, repeat three times; introduce 43.0g of pre-cooled vinyl acetate into the vacuumized reactor, and then press 48.0g of trifluoropropene into the vacuumized reactor monomer, heating the reactor to 35°C; then carbon dioxide was pressed into the reactor with a high pressure plunger pump, and after the pressure reached 48MPa, 3.0g concentration of 4wt% (CF 3 CF 2 (CF 2 OCF (CF 3 )) 2 COO) 2 The 1,1,2-trifluorotrichloroethane solution was added to the reactor to initiate polymerization; after 8 hours of polymerization, the valve was slowly opened to recover carbon dioxide and remaining monomers, and fresh carbon dioxide was repeatedly filled to extract the copolymer, and finally collected As a product, 59.6 g of vinyl acetate and trifluoropropylene binary copolymer were obtained.

[0042] Mix 10.0g of vinyl acetate and tr...

Embodiment 3

[0046] Embodiment 3, the preparation of ternary fluororesin

[0047] Vacuumize the 1L reactor to remove water and air, pass carbon dioxide and then vacuumize, repeat three times; introduce 43.0g of pre-cooled vinyl acetate into the vacuumized reactor, and then press 48.0g of trifluoropropene into the vacuumized reactor monomer, heating the reactor to 35°C; then carbon dioxide was pressed into the reactor with a high-pressure plunger pump, and after the pressure reached 65MPa, 2.5g of 4wt% (CF 3 CF 2 (CF 2 OCF (CF 3 )) 2 COO) 2 The 1,1,2-trifluorotrichloroethane solution was added to the reactor to initiate polymerization; after 7 hours of polymerization, the valve was slowly opened to recover carbon dioxide and remaining monomers, and fresh carbon dioxide was repeatedly filled to extract the copolymer, and finally collected As a product, 59.9 g of a binary copolymer of vinyl acetate and trifluoropropylene was obtained.

[0048] Mix 10.0g of vinyl acetate and trifluoropro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com