Application of block polymer as dielectric elastomer

A technology of block polymers and dielectric elastomers, which is applied in the application field of block polymers as dielectric elastomers, can solve the problems of restricting the application of dielectric elastomers, high transportation costs, and high storage costs, and achieve a matching solution Flexible, High Power Density, Fast Response Effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Example 1: Poly(styrene-b-n-butyl acrylate-b-styrene) triblock copolymer

[0033] In this example, the RAFT reversible addition-fragmentation chain transfer emulsion polymerization method is used for material preparation, and the specific steps are as follows:

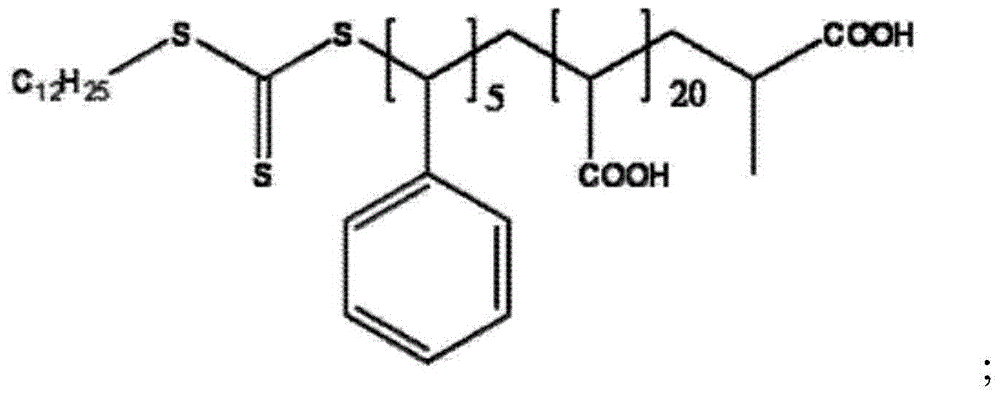

[0034] (1) Add 30 parts by weight of water, 1 part by weight of RAFT amphiphilic macromolecular reversible addition and fragmentation chain transfer reagent, and 10 parts by weight of styrene into the reaction device, wherein the RAFT amphiphilic macromolecular reversible addition and fragmentation chain transfer reagent The molecular formula is:

[0035]

[0036] Stir and mix the above raw materials, blow nitrogen, heat up to 80°C, add 0.01 parts by weight of a water-soluble initiator, initiate polymerization for 5 hours, add an aqueous solution containing 2 parts by weight of alkali, slowly add monomer butyl acrylate, and continue polymerization for 5 hours After 1 hour, add 30 parts of water and 10 parts ...

Embodiment 2

[0044] Example 2: Poly(styrene-b-n-butyl acrylate-b-styrene) triblock copolymer

[0045] In this example, the RAFT reversible addition-fragmentation chain transfer emulsion polymerization method is used for material preparation, and the preparation method is similar to that in Example 1.

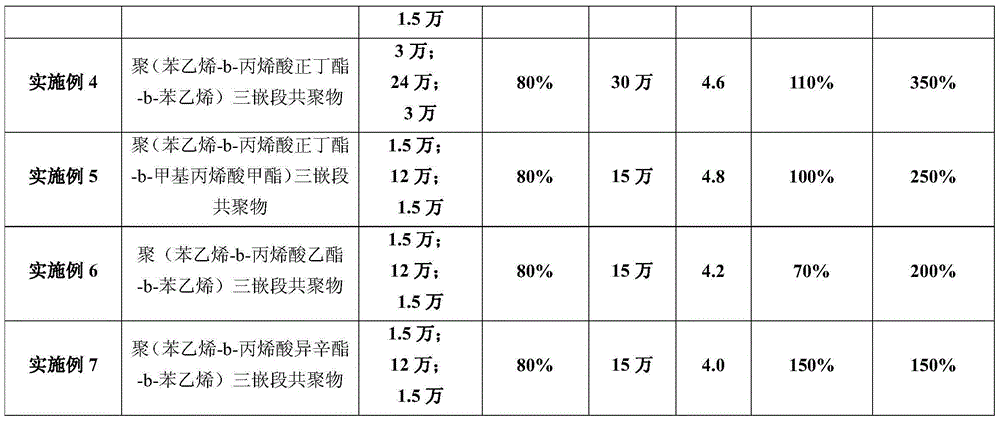

[0046] The specific molecular chain structure of the block copolymer prepared in this example is shown in Table 1, wherein the mass percentage of n-butyl acrylate is 75%, and the total molecular weight is 120,000.

[0047] The solid product prepared above was configured into a 5% tetrahydrofuran solution, poured into a polytetrafluoroethylene watch glass, volatilized to form a film, the heating temperature was 80°C, put it into a vacuum oven after volatilizing for 24 hours, and annealed at 120°C for 24 Hours, a new type of dielectric elastomer film was obtained.

[0048] Performance Testing

[0049] Dielectric constant measurement: the novel dielectric elastomer prepared in this example wa...

Embodiment 3

[0051] Example 3: Poly(styrene-b-n-butyl acrylate-b-styrene) triblock copolymer

[0052] In this example, the RAFT reversible addition-fragmentation chain transfer emulsion polymerization method is used for material preparation, and the preparation method is similar to that in Example 1.

[0053] The specific molecular chain structure of the block copolymer prepared in this example is shown in Table 1, wherein the mass percentage of n-butyl acrylate is 85%, and the total molecular weight is 200,000.

[0054] The solid product prepared above was configured into a 5% tetrahydrofuran solution, poured into a polytetrafluoroethylene watch glass, volatilized to form a film, the heating temperature was 80°C, put it into a vacuum oven after volatilizing for 24 hours, and annealed at 120°C for 24 Hours, a new type of dielectric elastomer film was obtained.

[0055] Performance Testing

[0056] Dielectric constant measurement: the novel dielectric elastomer prepared in this example wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com