Method for preparing CdSe/CdS nuclear shell semiconductor quantum dots at normal temperature

A technology for semiconductors and quantum dots, which is applied in the field of preparing CdSe/CdS core-shell semiconductor quantum dots, can solve problems such as unfavorable solubility of quantum dots and decrease in conductivity of nanoparticles, and achieves mild reaction conditions, simple process and wide application prospects. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

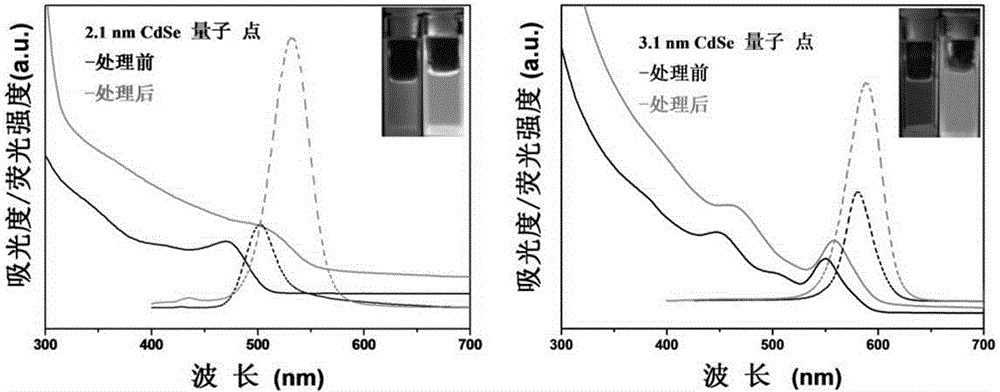

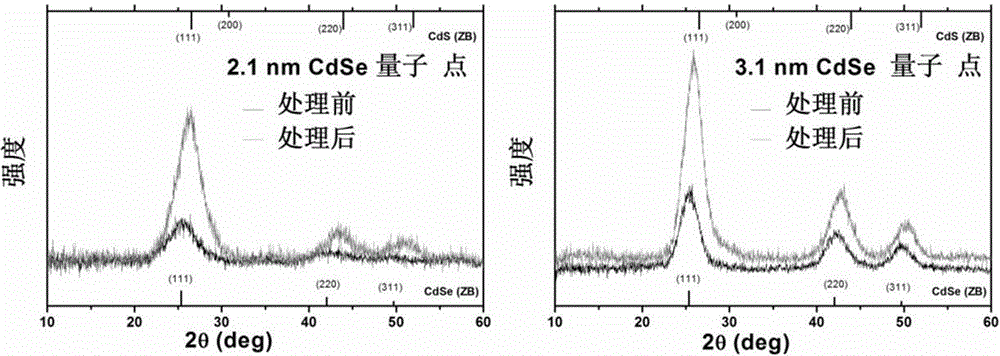

[0020] 1.1 Synthesis of 2nm CdSe quantum dots by oil phase method. Synthesis of 2nmCdSe quantum dots. 256mg CdO, 3.5mL oleylamine and 40mL octadecene were heated to 220°C and kept at 220°C until the solution was colorless and clear. Then the solution was reduced to 120°C and vacuum was applied for 1 hour. In N 2 Under the conditions, 2mL TOP dissolved with 316mg Se powder was injected into the precursor solution of Cd. React for 10 minutes and cool down. Wash and finally dissolve in n-hexane solution.

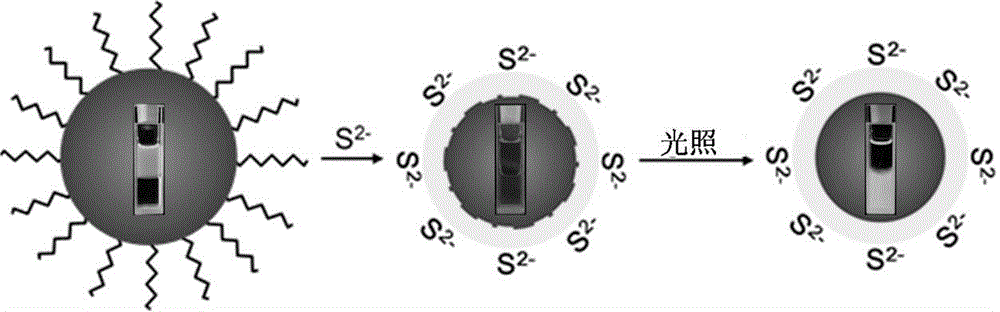

[0021] 1.2S 2- Surface treatment quantum dot particles

[0022] 1.2.1(NH 4 ) 2 S surface treatment. At room temperature, use (NH 4 ) 2 S (40%-48% aqueous solution) formamide solution treats CdSe quantum dots to exchange semiconductor nanoparticles into formamide. Wash the CdSe / CdS core-shell semiconductor nanoparticles with acetone to remove excess S 2- , And finally dissolved in formamide.

[0023] 1.2.2K 2 S surface treatment. At room temperature, use K 2 S formamide solutio...

Embodiment 2

[0026] 2.1 Synthesis of 3nm CdSe quantum dots by oil phase method. 3nmCdSe quantum dot synthesis. 77mgCdO, 757μL oleylamine, 30mL octadecene in N 2 Heat to 250°C and keep until the solution becomes clear. Cool down to 120°C and vacuum for 1h. Under N2 conditions, heat the solution to 240°C and keep it for 3 minutes. Add 1mL of oleylamine, 1mL of oleic acid and 4mL of octadecene mixture and inject it at a rate of 1mL / min. The reaction was kept at 240°C for 30 minutes. Reduce to room temperature, wash, and finally dissolve in n-hexane solution.

[0027] 2.2.1(NH 4 ) 2 S surface treatment. At room temperature, use (NH 4 ) 2 S (40%-48% aqueous solution) formamide solution treats CdSe quantum dots to exchange semiconductor nanoparticles into formamide. Wash the CdSe / CdS core-shell semiconductor nanoparticles with acetone to remove excess S 2- , And finally dissolved in formamide.

[0028] 2.2.2K 2 S surface treatment. At room temperature, use K 2 S formamide solution treats CdSe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com