Negative-pressure debenzylation device and negative-pressure debenzolization method

A technology for removing benzene and negative pressure, applied in chemical instruments and methods, hydrocarbons, organic chemistry, etc., can solve the problems of high production consumption, low quality, low recovery rate, etc., and achieve the effect of easy separation and condensation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in combination with specific embodiments.

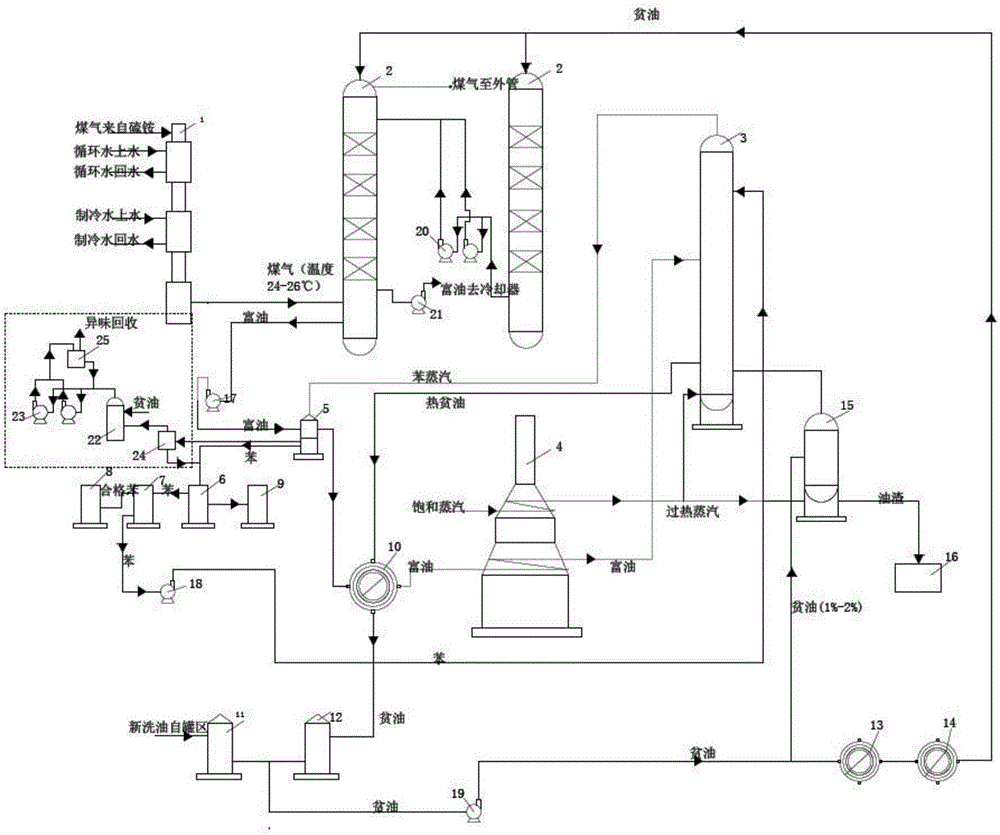

[0024] A negative pressure benzene removal device, comprising a final cooler 1, a benzene washing tower 2, a benzene removal tower 3, a tube furnace 4, a crude benzene condensation cooler 5, an oil-water separator 6, a crude benzene reflux tank 7, and a crude benzene intermediate Tank 8, control separator 9, lean-rich oil heat exchanger 10, new oil washing tank 11, lean oil tank 12, first-stage lean-oil cooler 13, second-stage lean-oil cooler 14, regenerator 15, slag discharge tank 16, second-stage lean oil cooler A rich oil pump 17, a benzene benzene return pump 18, a lean oil pump 19, a semi-rich oil pump 20, a second rich oil pump 21, a mist trap tower 22, a vacuum pump 23, a vacuum tank 24, and a vacuum pump circulation tank 25;

[0025] The final cooler 1 is connected with a circulating water upper water channel, a circulating water return channel, a cooling water uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com