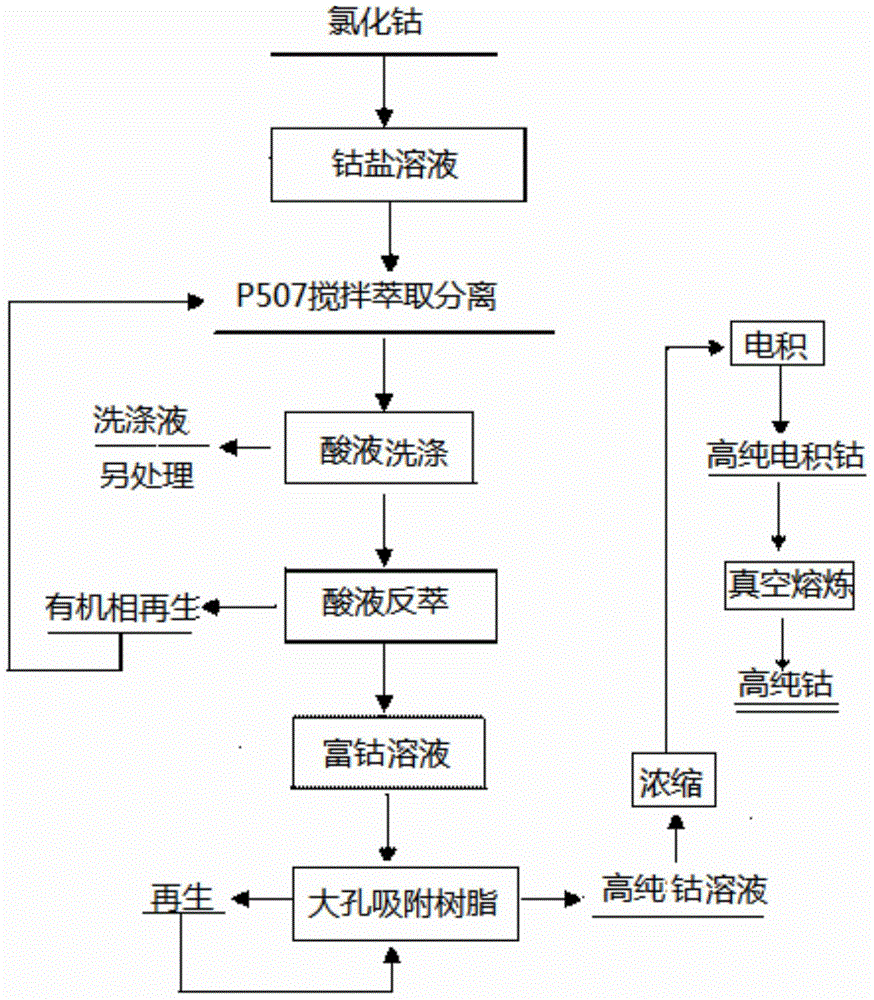

Method for preparing high-pure-cobalt solution through stirring and extraction

A cobalt solution, high-purity technology, applied in the direction of improving process efficiency, etc., can solve the problems of difficult control of pH value in the column, low column extraction capacity, affecting industrial applications, etc., so that the reaction process is clearly visible and conducive to the regulation of process conditions , easy-to-grasp effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] (1) Pump 20 liters of pure water into the high-level extraction tank, start stirring at a stirring speed of 60 rpm, add 3.3 kg of cobalt chloride, and make a cobalt salt solution containing 40 g / L of cobalt. (2) Pump 16 liters of sulfonated kerosene and 4 liters of P507 extractant into the low-level extraction tank, stir evenly and add 800 ml of 12mol / L NaOH solution for saponification. (3) Open the agitation in the high-level extraction tank, open the flowmeter at the same time, adjust the flow to 10 liters / min of the extractant, control the ratio (organic extractant: cobalt chloride solution volume ratio) to 2:1, at room temperature The cobalt solution is subjected to single-stage extraction, and the two phases are stirred and mixed for 10 minutes. The cobalt enters the organic phase to obtain a cobalt-containing loaded organic phase, which is left to stand for 30 minutes. The discharge valve at the bottom of the high-level extraction tank is opened to discharge the wa...

Embodiment 2

[0051] (1) Pump 20 liters of pure water into the high-level extraction tank, start stirring at a stirring speed of 60 rpm, add 4.95 kg of cobalt chloride salt, and prepare a cobalt solution containing 60 g / L of cobalt. (2) Pump 15 liters of sulfonated kerosene and 3 liters of P507 extractant into the low-level extraction tank, stir evenly and add 514 ml of 12 mol / L NaOH solution for saponification. (3) Open the stirring in the high-level extraction tank, open the flow meter simultaneously, adjust the flow rate to 10 liters / min of the extractant, control the ratio (organic extractant: cobalt chloride solution) to be 3:1, at room temperature to cobalt The solution is extracted, the two phases are stirred and mixed for 20 minutes, and the cobalt enters the organic phase to obtain a cobalt-containing loaded organic phase, which is left to stand for 30 minutes, and the discharge valve at the bottom of the high-level extraction tank is opened to discharge the waste water. (4) In the...

Embodiment 3

[0056] (1) Pump 20 liters of pure water into the high-level extraction tank, start stirring at a stirring speed of 60 rpm, add 6.6 kg of cobalt chloride, and prepare a cobalt salt solution containing 80 g / L of cobalt. (2) Pump 18 liters of sulfonated kerosene and 4 liters of P507 extractant into the low-level extraction tank, stir evenly and add 733ml of 12mol / L NaOH solution for saponification. (3) Open the stirring in the high-level extraction tank, open the flow meter simultaneously, adjust the flow rate to 15 liters / min of the extractant, control the ratio (organic extractant: cobalt chloride solution) to be 2.5:1, at room temperature to cobalt The solution is subjected to single-stage extraction, and the two phases are stirred and mixed for 15 minutes. The cobalt enters the organic phase to obtain a cobalt-containing organic phase. After standing for 30 minutes, the discharge valve at the bottom of the high-level extraction tank is opened to discharge the waste water. (4)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com