Under-construction mass concrete intelligent water cooling control method and system

A large-volume concrete and control system technology, applied in construction, infrastructure engineering, etc., can solve problems such as uncontrollable, far apart, and affect the actual control effect, and achieve the effect of easy inspection and management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

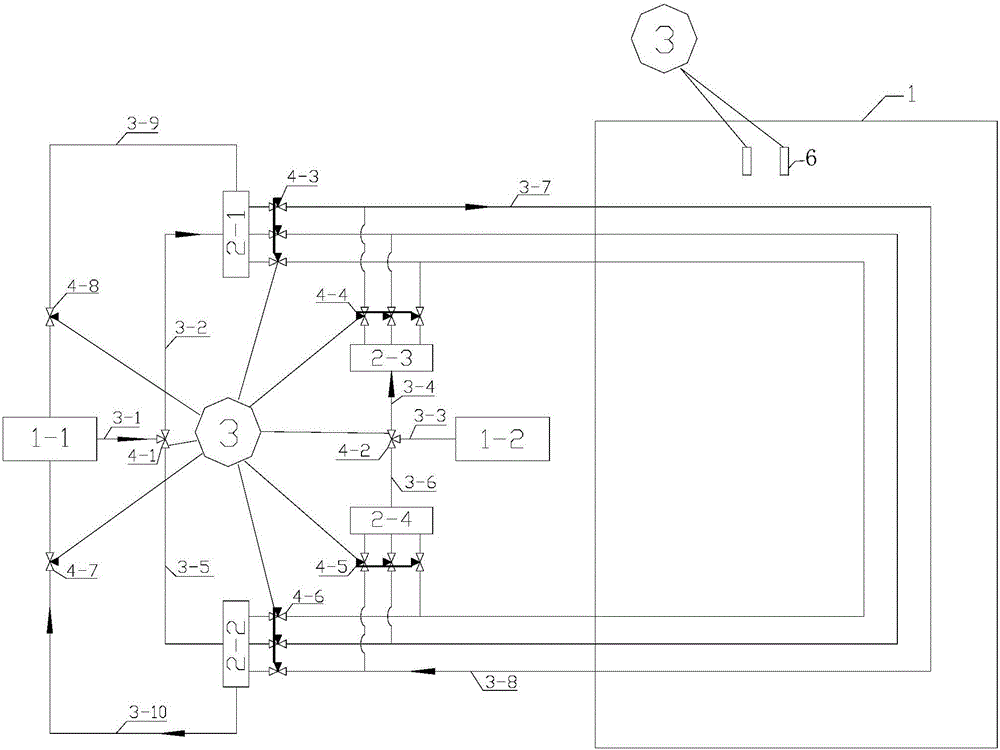

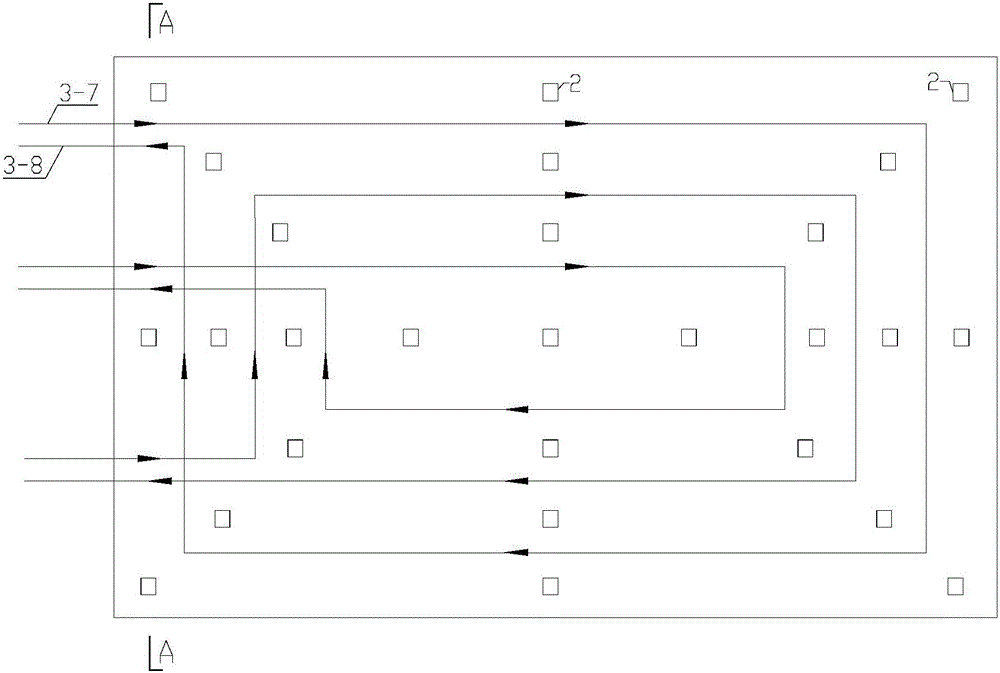

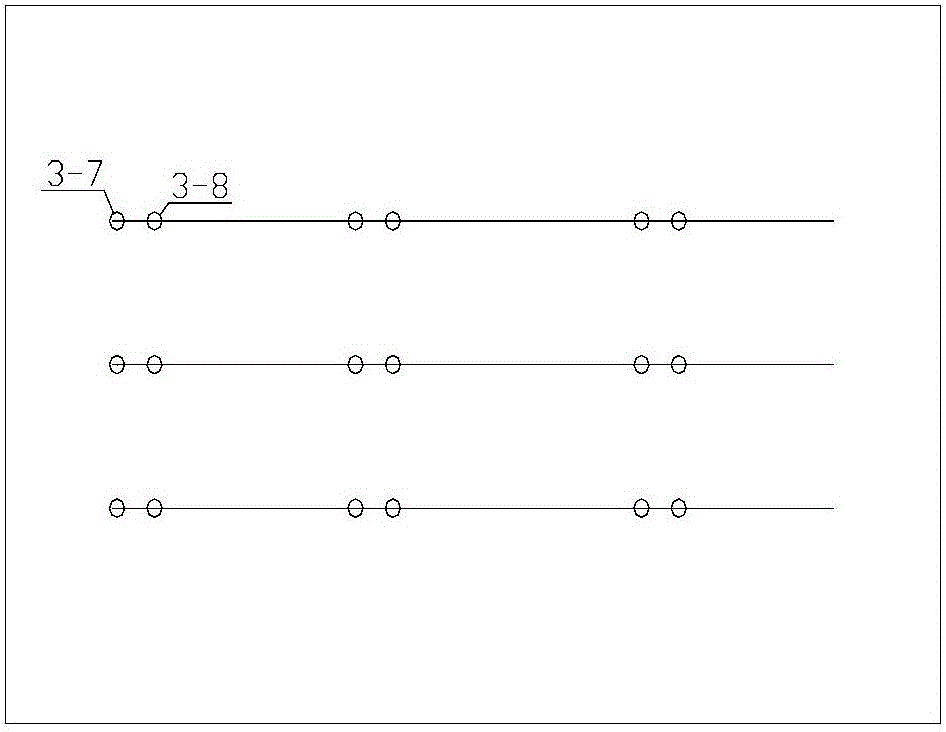

Method used

Image

Examples

Embodiment

[0083] Take a large-volume concrete block with a size of 14m(X)×6m(Y)×4m(Z) as the object, take C30 concrete, and its matching ratio in Table 1 below. Use ANSYS finite element software to perform temperature field simulation simulations of traditional water cooling technology, the technical solution of the present invention, and three solutions without water cooling. Solid70 unit discrete concrete and fluid116 unit are used to simulate the action of water pipes, and the calculation step is set to 1h. The ambient temperature is set at 20℃, the concrete entering temperature is 25℃, the pipe diameter is 80mm (galvanized iron pipe), the concrete adiabatic temperature rise curve adopts the compound index formula, and the total heat of hydration of the cement used is Q 0 =330kJ / kg, the thermodynamic parameters of concrete and cooling water are shown in Tables 2 and 3:

[0084] Table 1 Concrete construction mix ratio (kg / m 3 )

[0085] Name

Water

Sand

Stone

Admixture

Admi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com