Formula and preparation method of simulated low-level organic waste liquid pyrolysis incineration suspension

A technology of organic waste liquid and suspension, applied in combustion methods, lighting and heating equipment, incinerators, etc., can solve problems such as high sedimentation speed, and achieve the effect of less sedimentation, low viscosity and easy transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

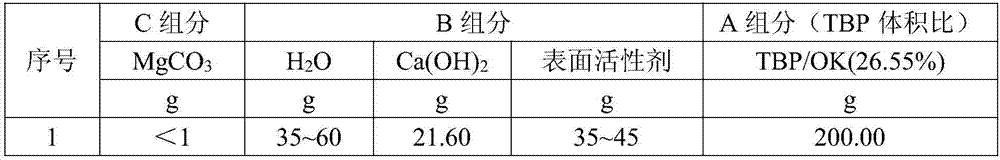

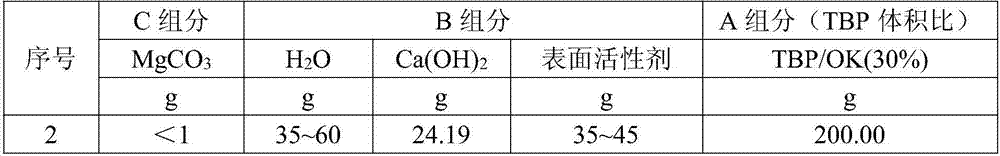

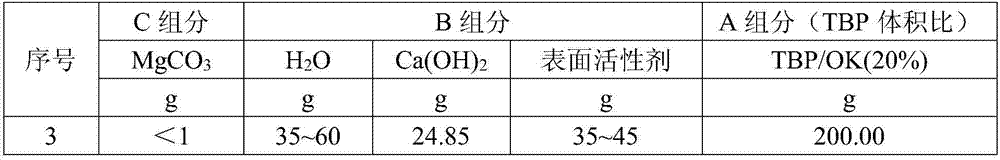

Examples

preparation example Construction

[0036] The preparation method of the above simulated low-level organic waste liquid pyrolysis incineration suspension formula comprises the following steps:

[0037] Step 1, prepare component A; first measure tributyl phosphate with a volume ratio of 26.55%, then mix aviation hydrogenated kerosene with a volume ratio of 73.23% into tributyl phosphate, stir for 10 minutes, and then dibutyl phosphate by The volume ratio is 0.12%, mixed with the mixed solution of tributyl phosphate and kerosene, and set aside;

[0038] Step 2, preparing component B; first mix 27% mass ratio of phosphorus-fixing agent calcium hydroxide with 38% deionized water, stir for 10 minutes, then add 35% active agent into the stirring milk of lime, and then Stir for 10min, set aside;

[0039] Step 3, preparing the simulated waste liquid suspension; while stirring, slowly pour the B component prepared in step 2 into the stirring simulated low-level organic waste liquid A, and stir for 30 minutes to form a u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com