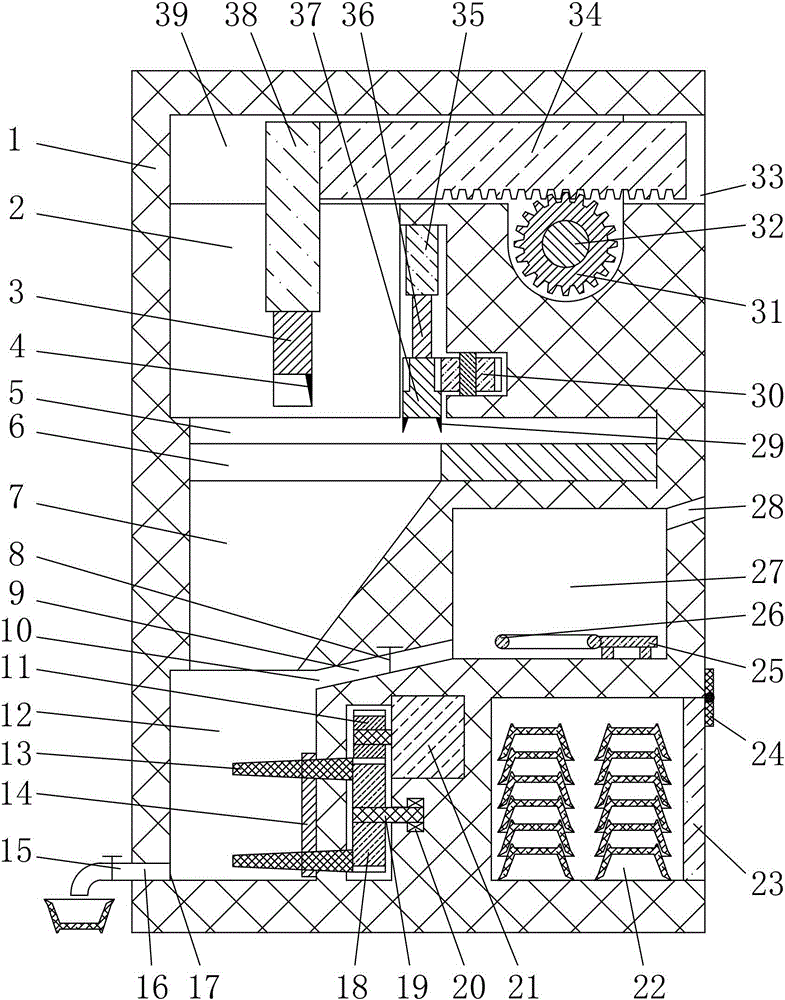

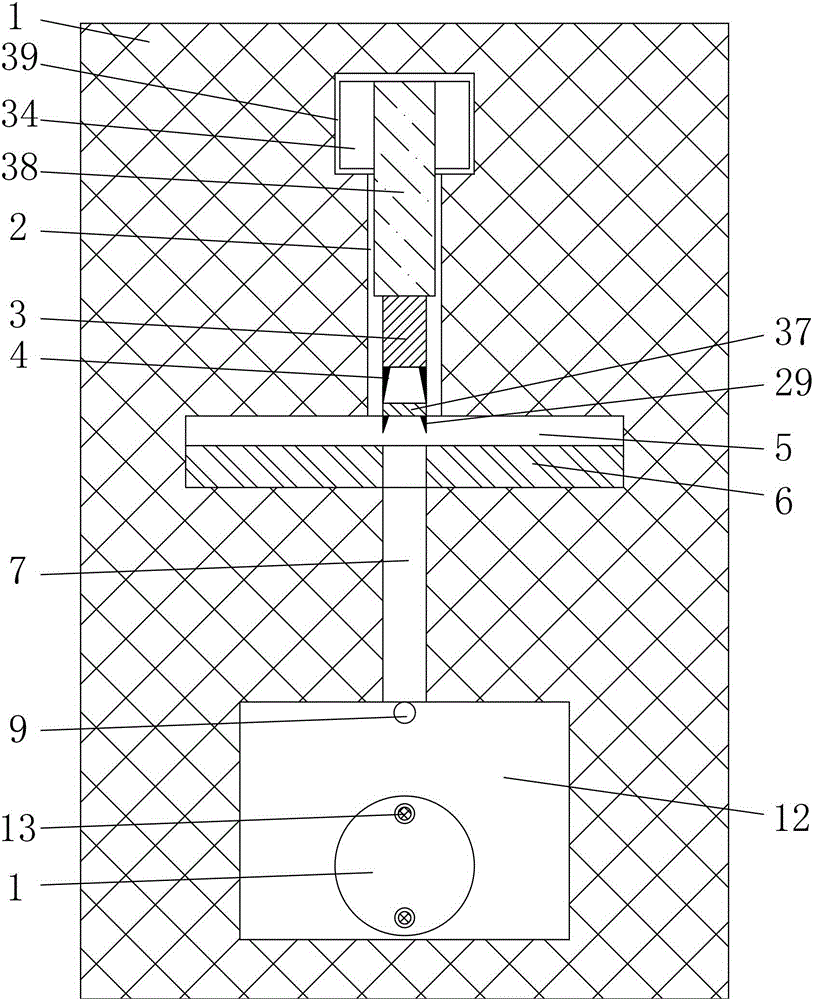

Tea cooking machine for Pu-erh tea

A tea making machine and Pu-erh tea technology, applied in applications, kitchen utensils, home utensils, etc., can solve problems such as difficulty in taking tea and brewing tea, and achieve excellent high temperature resistance, excellent adhesion, and excellent weather resistance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A heat-resistant ink, consisting of the following components in parts by weight:

[0040] 19 parts of melamine formaldehyde resin modified by β-hydroxyethyl acrylate; 30 parts of hyperbranched resin; 4 parts of diglycidyl hexahydrophthalate; 4 parts of polypropylene glycol diglycidyl ether; 4,5-epoxycyclohexyl 12 parts of diglycidyl alkane-1,2-dicarboxylate; 10 parts of talc; 10 parts of kaolin; 10 parts of carbon black; 1 part of defoamer; 1 part of leveling agent; 1 part of antioxidant; 1 part of dispersant ; 14 parts of propylene glycol methyl ether acetate; 2 parts of triethylenetetramine.

[0041] After testing, it can be seen that the curing temperature of this embodiment is 90°C.

[0042] When in use, dry and solidify within 90-100°C for 2 minutes. The dry film thickness is controlled at 25-30μm. Then it was aged in a forced air oven at 100° C. for 60 minutes.

[0043] The performance test methods and results are as follows:

[0044] Pre-bake (75°C): 25 minu...

Embodiment 2

[0052] A heat-resistant ink, consisting of the following components in parts by weight:

[0053] 13 parts of melamine formaldehyde resin modified by β-hydroxyethyl acrylate; 31 parts of hyperbranched resin; 6 parts of diglycidyl hexahydrophthalate; 5 parts of polypropylene glycol diglycidyl ether; 4,5-epoxycyclohexyl 10 parts of diglycidyl alkane-1,2-dicarboxylate; 5 parts of calcium carbonate; 13 parts of aluminum hydroxide; 13 parts of carbon black; 1 part of defoamer; 1 part of leveling agent; 1 part of antioxidant; dispersant 1 part; 6 parts of acetone; 3 parts of triethylenetetramine.

[0054] After testing, it can be seen that the curing temperature of this embodiment is 90°C.

[0055] When in use, dry and solidify within 90-100°C for 2 minutes. The dry film thickness is controlled at 25-30μm. Then it was aged in a forced air oven at 100° C. for 60 minutes.

[0056] The performance test methods and results are as follows:

[0057] Pre-bake (75°C): 25 minutes. After...

Embodiment 3

[0065] A heat-resistant ink, consisting of the following components in parts by weight:

[0066] 22 parts of β-hydroxyethyl acrylate modified melamine formaldehyde resin; 25 parts of hyperbranched resin; 5 parts of diglycidyl hexahydrophthalate; 7 parts of polypropylene glycol diglycidyl ether; 4,5-epoxycyclohexyl 13 parts of diglycidyl alkane-1,2-dicarboxylate; 10 parts of calcium carbonate; 8 parts of talcum powder; 13 parts of carbon black; 1 part of defoamer; 1 part of leveling agent; 1 part of antioxidant; 1 part of dispersant 11 parts; 11 parts of ethylene glycol ether; 3 parts of triethylenetetramine.

[0067] After testing, it can be seen that the curing temperature of this embodiment is 90°C.

[0068] When in use, dry and solidify within 90-100°C for 2 minutes. The dry film thickness is controlled at 25-30μm. Then it was aged in a forced air oven at 100° C. for 60 minutes.

[0069] The performance test methods and results are as follows:

[0070] Pre-bake (75°C):...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| gloss | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com