Single-gas-phase fluidized bed reactor discharging openings applicable to multiregion polyreaction

A technology of gas-phase fluidized bed and polymerization reaction, which is applied in the direction of chemical instruments and methods, chemical/physical processes, etc. It can solve the problems of condensing agent waste, waste, and blockage of discharge pipelines, so as to ensure the fluidity of materials and reduce the residence time. , the effect of protecting particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

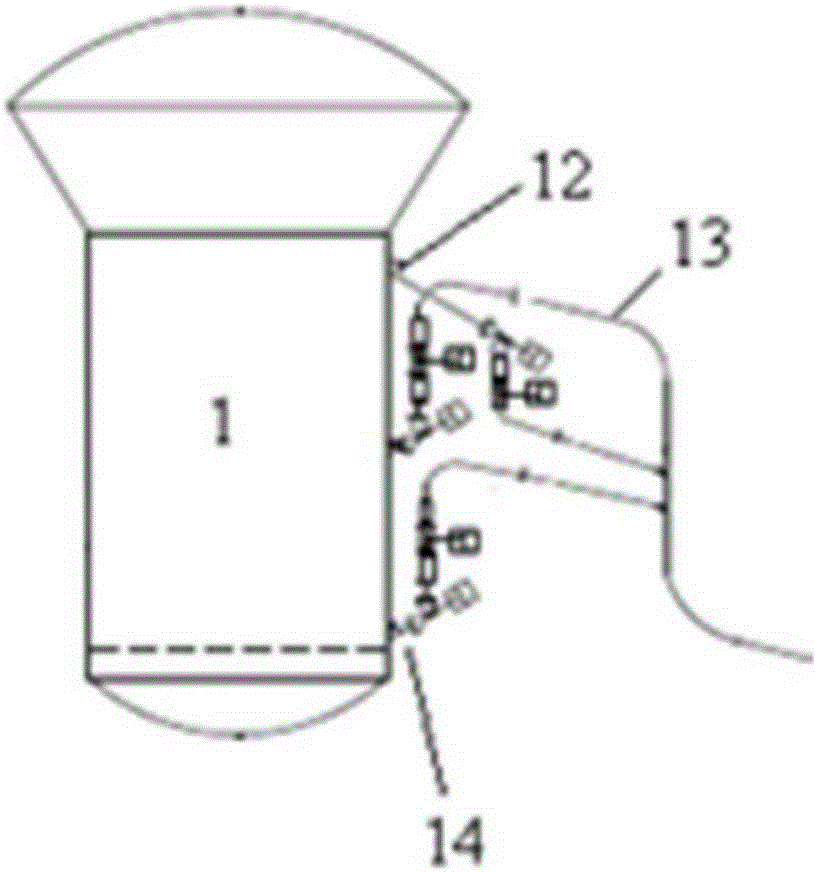

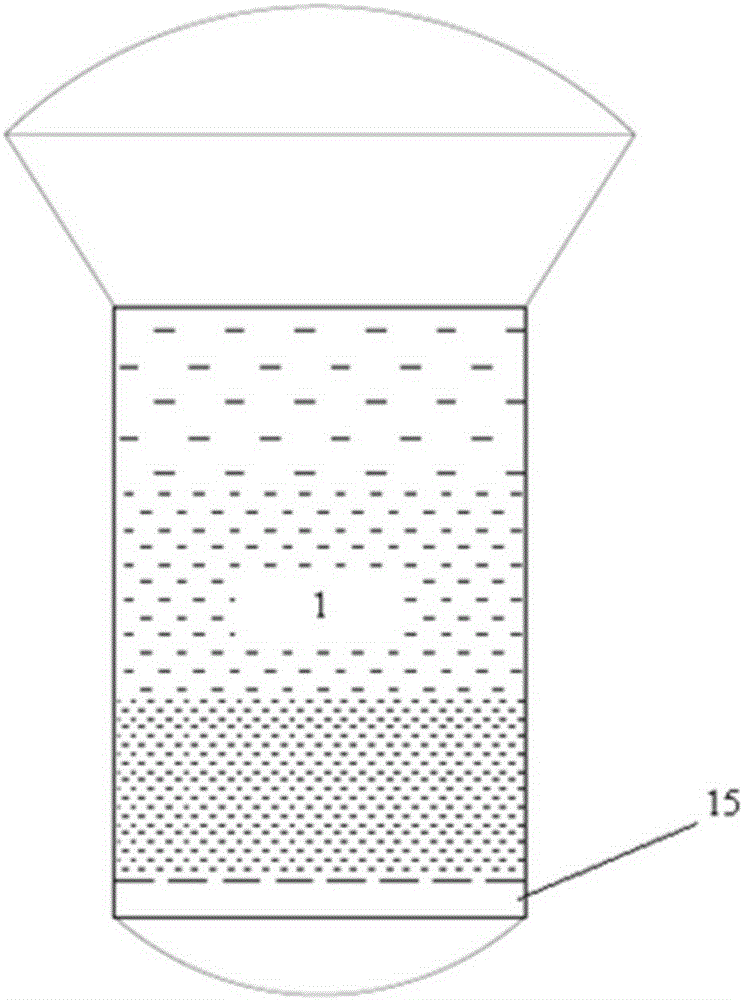

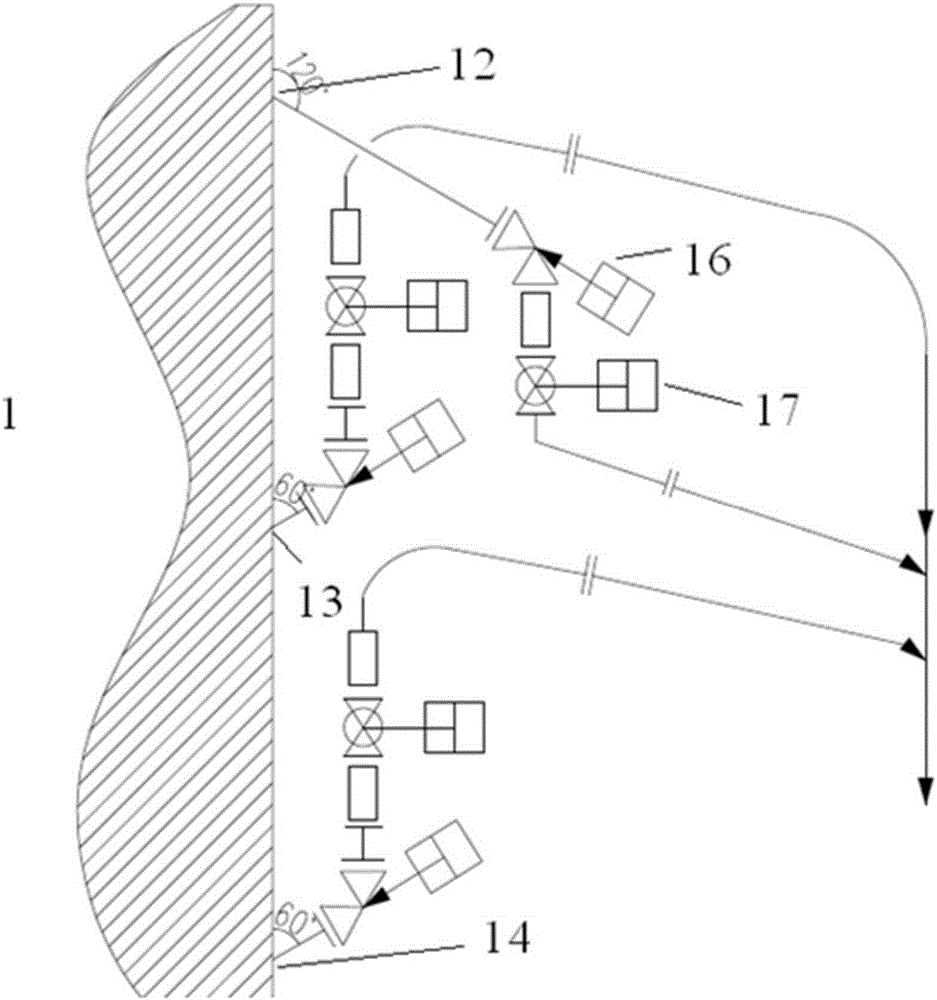

Embodiment 1

[0029] Taking a set of gas-phase fluidized bed reactor with an annual output of 300,000 tons of linear low-density polyethylene (LLDPE) as an example, its design load is usually 37.5T / HR, and it produces conventional unimodal LLDPE film products, with an hourly discharge of about 25 times, the inlet temperature of the fluidized bed is about 39°C, and the discharge temperature is about 60-65°C. The gas-phase fluidized bed reactor 1 with the discharge port is as figure 1 As shown, the discharge port is arranged on the gas-phase fluidized bed reactor 1, and the discharge port is provided with three layers, which are respectively the upper layer discharge port 12, the middle layer discharge port 13 and the lower layer discharge port 14, Each discharge port is equipped with a plunger valve 16 for isolation, and each plunger valve 16 is connected to an electric rotary valve 17, and the rotation speed and rotation mode of the electric rotary valve 17 are controlled by setting the mate...

Embodiment 2

[0031] Taking a set of gas-phase fluidized bed reactor with an annual output of 300,000 tons of linear low-density polyethylene (LLDPE) as an example, its design load is usually 37.5T / HR, and it produces conventional unimodal LLDPE film products, with an hourly discharge of about 25 times, the inlet temperature of the fluidized bed is about 39°C, and the discharge temperature is about 60-65°C. The gas-phase fluidized bed reactor 1 with the discharge port is as figure 1 As shown, the discharge port is arranged on the gas-phase fluidized bed reactor 1, and the discharge port is provided with three layers, which are respectively the upper layer discharge port 12, the middle layer discharge port 13 and the lower layer discharge port 14, Each discharge port is equipped with a plunger valve 16 for isolation, and each plunger valve 16 is connected to an electric rotary valve 17, and the rotation speed and rotation mode of the electric rotary valve 17 are controlled by setting the mate...

Embodiment 3

[0033] Taking a set of gas-phase fluidized bed reactor with an annual output of 300,000 tons of linear low-density polyethylene (LLDPE) as an example, its design load is usually 37.5T / HR, and it produces conventional unimodal LLDPE film products, with an hourly discharge of about 25 times, the inlet temperature of the fluidized bed is about 39°C, and the discharge temperature is about 60-65°C. The gas-phase fluidized bed reactor 1 with the discharge port is as figure 1 As shown, the discharge port is arranged on the gas-phase fluidized bed reactor 1, and the discharge port is provided with three layers, which are respectively the upper layer discharge port 12, the middle layer discharge port 13 and the lower layer discharge port 14, Each discharge port is equipped with a plunger valve 16 for isolation, and each plunger valve 16 is connected to an electric rotary valve 17, and the rotation speed and rotation mode of the electric rotary valve 17 are controlled by setting the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com