In-place regenerating activating furnace, system and method for saturated active carbon

A technology for regenerating activated carbon, applied in chemical instruments and methods, separation methods, filter regeneration, etc., can solve the problem of high recycling cost of saturated activated carbon, achieve good social and environmental benefits, and reduce operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the invention is capable of various changes in different embodiments without departing from the scope of the invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

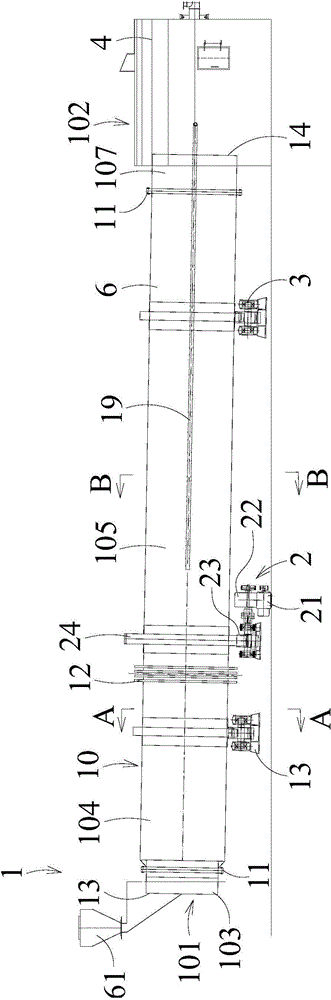

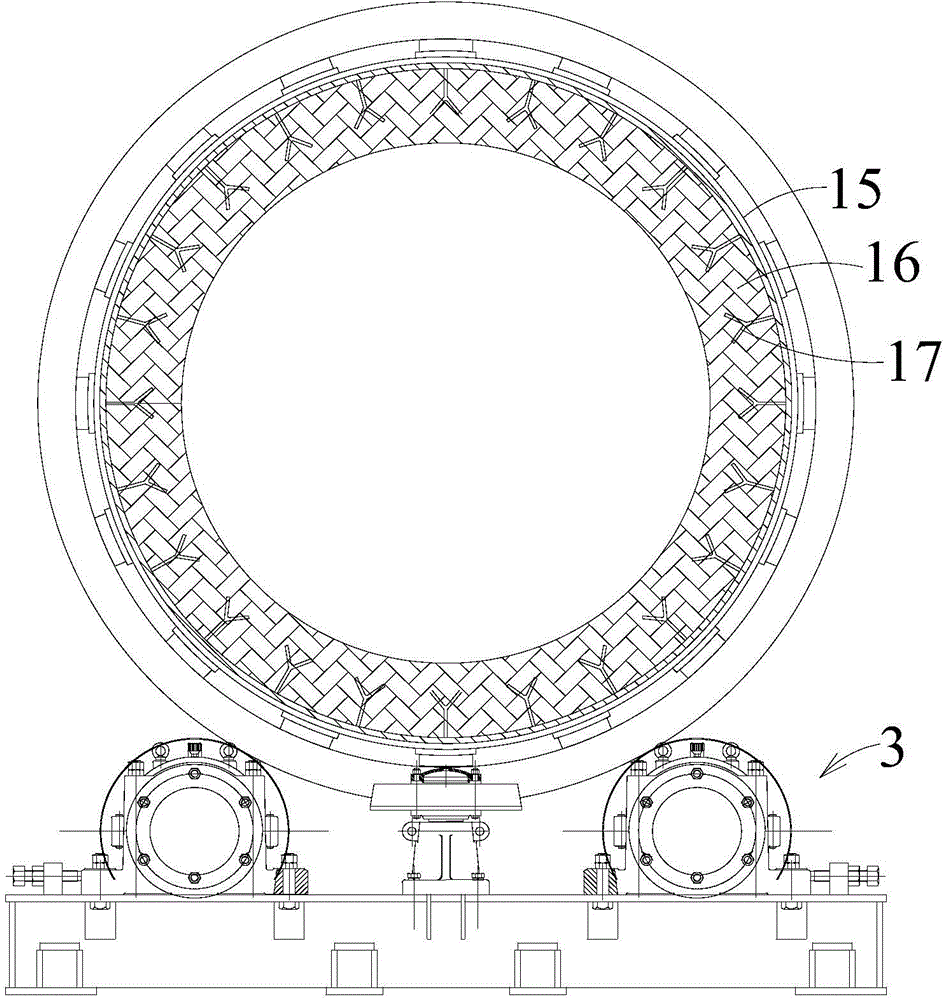

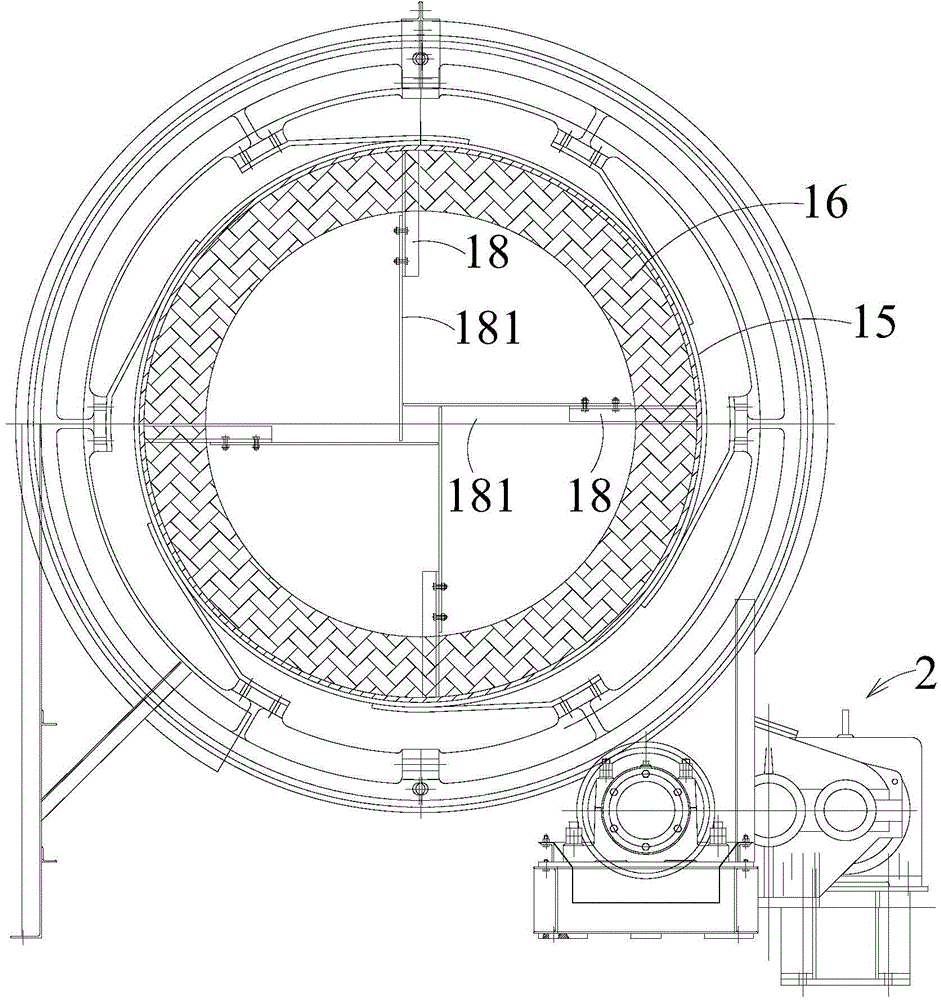

[0031] refer to Figure 4 As shown, the embodiment of the present invention provides an in-situ regeneration system for saturated activated carbon, which mainly includes a saturated silo 52, a conveying device 53, a regeneration activation furnace 1, a cooling machine 54, a conveyor 55, a regeneration silo 56, and a gas scrubber. Tower 57 and exhaust device 58. The connection sequence of the solid-phase material processing equipment can be: saturated silo 52 , conveying device 53 , regeneration and activation furnace 1 , cooling machine 54 , conveyor 55 and regeneration s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com