g-c3n4-zno/HNTs composite photocatalyst, preparation method therefor and application thereof

A g-c3n4-zno, composite light technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as human health threats, soil and water pollution, hidden dangers, etc., to achieve green Environmentally friendly and efficient pollution treatment technology, the effect of increasing specific surface area and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

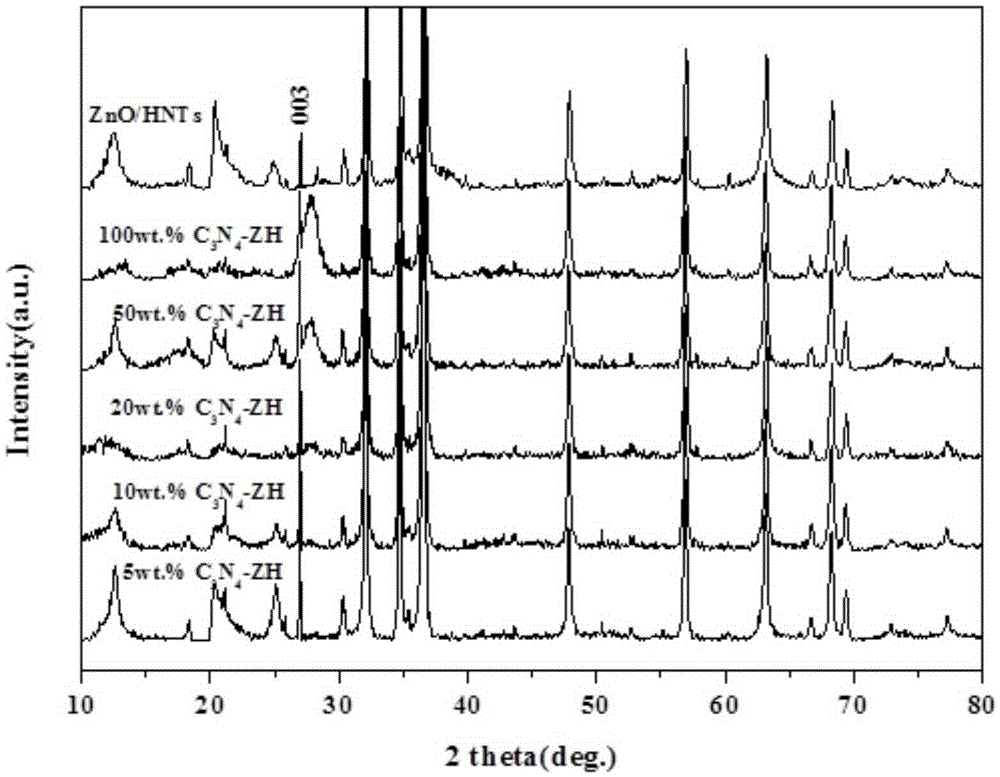

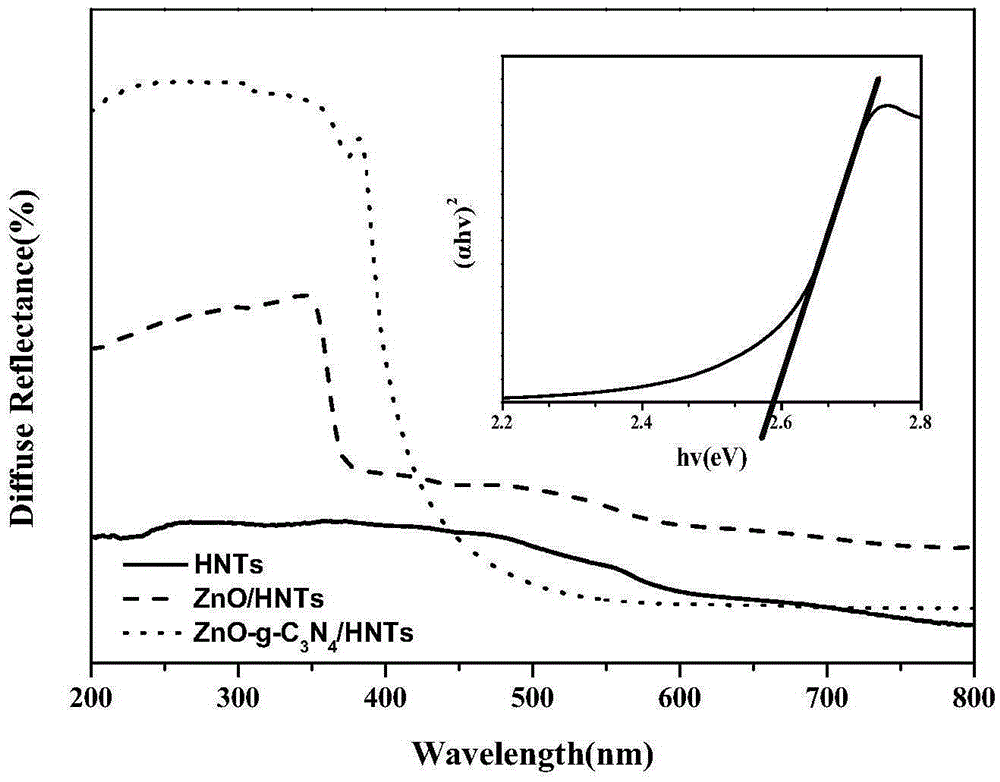

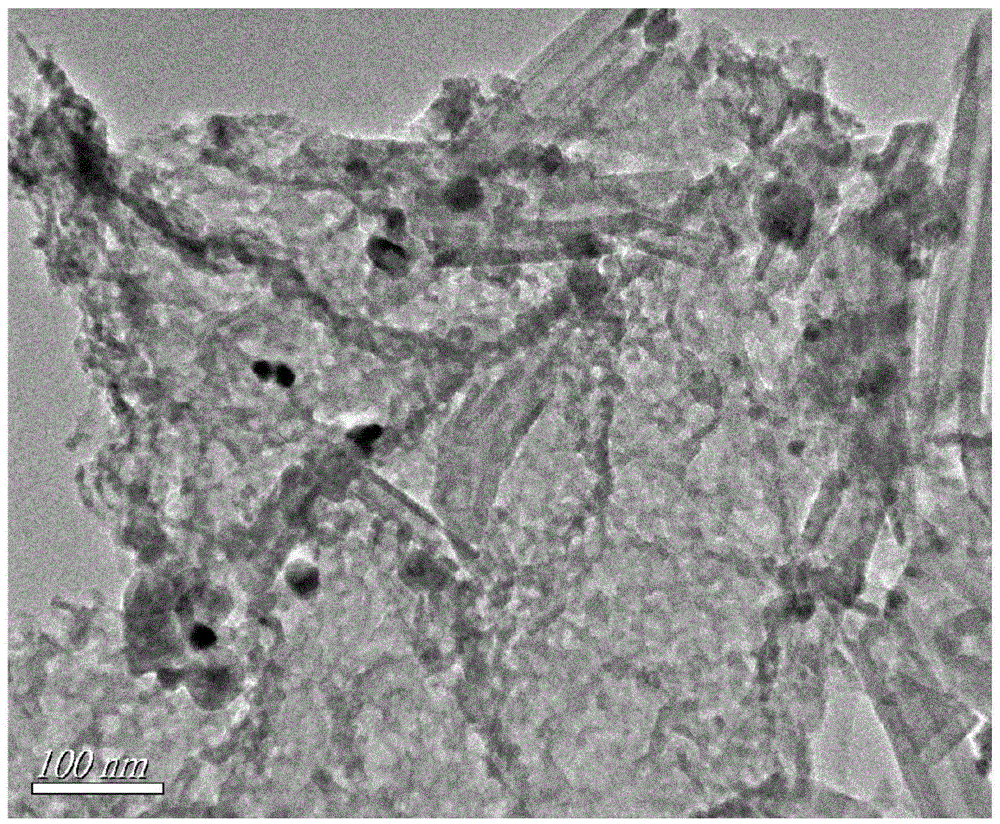

Method used

Image

Examples

Embodiment 1

[0031] (1) Preparation of ZnO / HNTs precursor:

[0032] Weigh 0.04gZn(NO 3 ) 2 ·6H 2 Put O (zinc nitrate hexahydrate) into a glass beaker, add 500mL of deionized water to dissolve it completely, stir it magnetically, then add 1.0g of halloysite nanotubes, stir and heat and evaporate to dryness, put the resulting solid into an agate mortar Grind to powder, put it into a muffle furnace, and calcinate at 400°C for 3 hours, and the obtained solid is the ZnO / HNTs precursor;

[0033] (2)g-C 3 N 4 - Preparation of ZnO / HNTs composite photocatalyst:

[0034] Weigh 0.212g of melamine and place it in a glass beaker, add ethanol to heat, and magnetically stir; then add 1.0g of the ZnO / HNTs precursor prepared in step (1) to the above mixed solution, fully magnetically stir and evaporate to dryness by heating to obtain a solid Grind to powder, put it into a muffle furnace for calcination at 520°C, wait for it to cool naturally to room temperature, take it out and grind it, the obtained...

Embodiment 2

[0037] (1) Preparation of ZnO / HNTs precursor:

[0038] Weigh 0.12gZn(NO 3 ) 2 ·6H 2Put O (zinc nitrate hexahydrate) into a glass beaker, add 500mL of deionized water to dissolve it completely, stir it magnetically, then add 1.0g of halloysite nanotubes, stir and heat and evaporate to dryness, put the resulting solid into an agate mortar Grind to powder, put it into a muffle furnace, and calcinate at 400°C for 3 hours, and the obtained solid is the ZnO / HNTs precursor;

[0039] (2)g-C 3 N 4 - Preparation of ZnO / HNTs composite photocatalyst:

[0040] Weigh 0.212g of melamine and place it in a glass beaker, add ethanol to heat, and magnetically stir; then add 1.0g of the ZnO / HNTs precursor prepared in step (1) to the above mixed solution, fully magnetically stir and evaporate to dryness by heating to obtain a solid Grind to powder, put it into a muffle furnace for calcination at 520°C, wait for it to cool naturally to room temperature, take it out and grind it, the obtained ...

Embodiment 3

[0043] (1) Preparation of ZnO / HNTs precursor:

[0044] Weigh 0.20gZn(NO 3 ) 2 ·6H 2 Put O (zinc nitrate hexahydrate) into a glass beaker, add 500mL of deionized water to dissolve it completely, stir it magnetically, then add 1.0g of halloysite nanotubes, stir and heat and evaporate to dryness, put the resulting solid into an agate mortar Grind to powder, put it into a muffle furnace, and calcinate at 400°C for 3 hours, and the obtained solid is the ZnO / HNTs precursor;

[0045] (2)g-C 3 N 4 - Preparation of ZnO / HNTs composite photocatalyst:

[0046] Weigh 0.212g of melamine and place it in a glass beaker, add ethanol to heat, and magnetically stir; then add 1.0g of the ZnO / HNTs precursor prepared in step (1) to the above mixed solution, fully magnetically stir and evaporate to dryness by heating to obtain a solid Grind to powder, put it into a muffle furnace for calcination at 520°C, wait for it to cool naturally to room temperature, take it out and grind it, the obtained...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com