Method for preparing carbon/carbon composite materials through 3D printing

A carbon composite material and 3D printing technology, which is applied in the direction of additive processing, etc., can solve the problems of mechanical properties that need to be improved, the preparation process of abrasive tools is complicated, and it is not suitable for 3D printing, so as to save mold processing steps and improve mechanical properties. performance, ensuring consistent results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

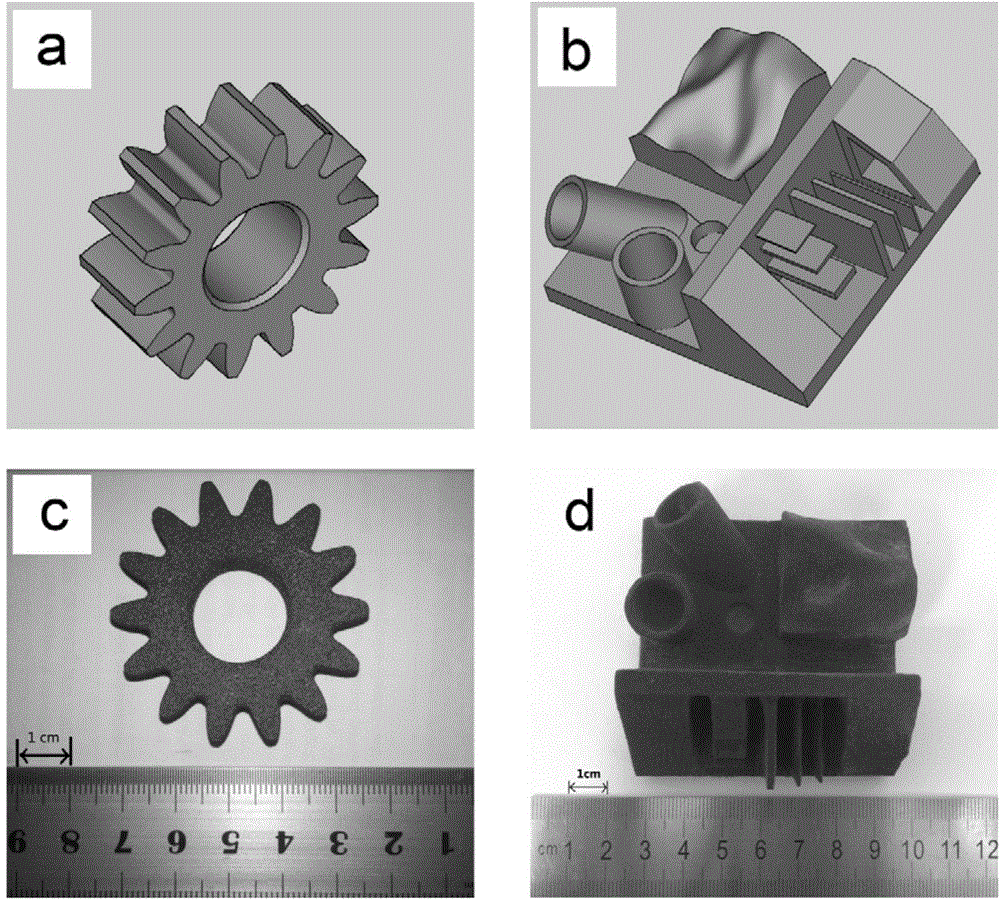

Image

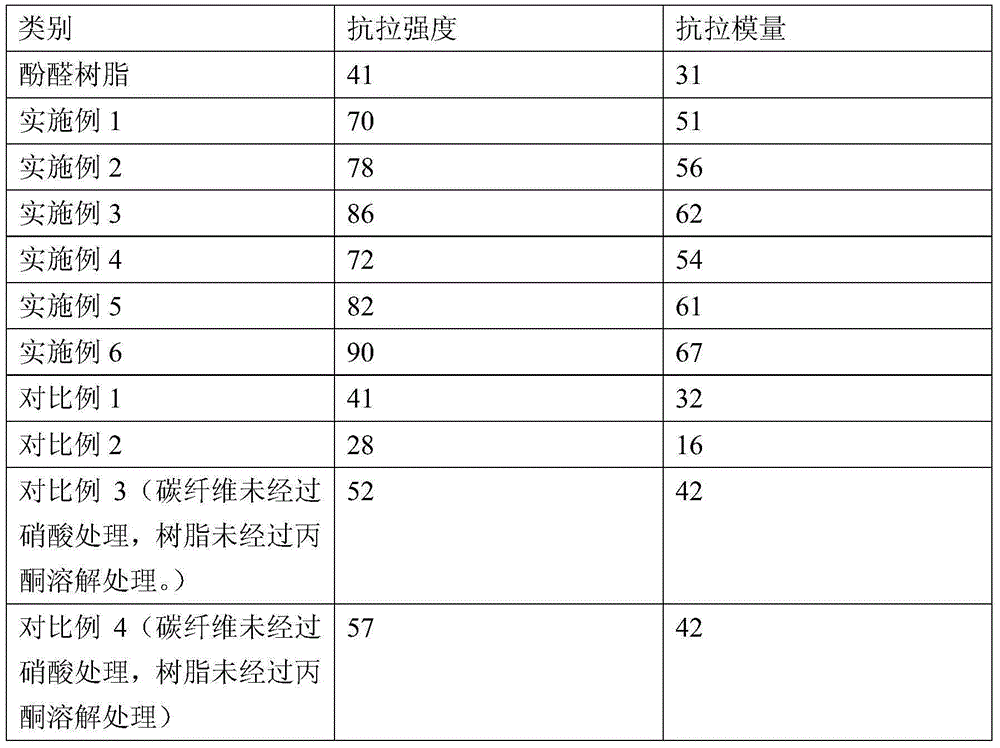

Examples

Embodiment 1

[0036] (1) Accurately weigh each component according to the following data: carbon fiber, 2kg, with an average diameter of 7μm, and a length range of 201μm-300μm; phenolic resin powder, 3kg, with a particle size range of 50μm-150μm; fumed silica, 10g ; Hexamethylenetetramine, 300g;

[0037](2) Disperse the carbon fibers in a nitric acid solution (67%) at 50°C for 3 hours with an ultrasonic stirrer. During this process, the surface of the carbon fibers was etched by nitric acid; the sample was dried in a vacuum filter drier at 140°C for 24 hours to finally obtain The carbon fiber after nitric acid etching, the etched carbon fiber and acetone are mixed in an ultrasonic stirrer with a mass ratio of 1:1 for 1 h;

[0038] (3) The phenolic resin powder is fully mixed with hexamethylenetetramine in a V-shaped mixer at a mass ratio of 10:1 for 2 hours;

[0039] (4) The liquid mixture and the powder mixture obtained in (2) and (3) are added into a 10L reaction vessel at the same time,...

Embodiment 2

[0043] (1) Accurately weigh each component according to the following data: carbon fiber 2Kg, with an average diameter of 7 μm, and a length range of 201 μm-300 μm; phenolic resin powder, 2 Kg, with a particle size range of 50 μm-150 μm; fumed silica, 10 g; Hexamethylenetetramine, 200g;

[0044] (2) Disperse the carbon fibers in a nitric acid solution (67%) at 50°C for 3 hours with an ultrasonic stirrer. During this process, the surface of the carbon fibers was etched by nitric acid; the sample was dried in a vacuum filter drier at 140°C for 24 hours to finally obtain The carbon fiber after nitric acid etching, the etched carbon fiber and acetone are mixed in an ultrasonic stirrer with a mass ratio of 1:1 for 1 h;

[0045] (3) The phenolic resin powder is fully mixed with hexamethylenetetramine in a V-shaped mixer at a mass ratio of 10:1 for 2 hours;

[0046] (4) The liquid mixture and the powder mixture obtained in (2) and (3) are added into a 10L reaction vessel at the same...

Embodiment 3

[0050] (1) Accurately weigh each component according to the following data: carbon fiber 3Kg, with an average diameter of 7 μm, and a length range of 201 μm-300 μm; phenolic resin powder, 2 Kg, with a particle size range of 50 μm-150 μm; fumed silica, 10 g; Hexamethylenetetramine, 200g;

[0051] (2) Disperse the carbon fibers in a nitric acid solution (67%) at 50°C for 3 hours with an ultrasonic stirrer. During this process, the surface of the carbon fibers was etched by nitric acid; the sample was dried in a vacuum filter drier at 140°C for 24 hours to finally obtain The carbon fiber after nitric acid etching, the etched carbon fiber and acetone are mixed in an ultrasonic stirrer with a mass ratio of 1:1 for 1 h;

[0052] (3) The phenolic resin powder is fully mixed with hexamethylenetetramine in a V-shaped mixer at a mass ratio of 10:1 for 2 hours;

[0053] (4) Add the liquid mixture and powder mixture obtained in (2) and (3) into a 10L reaction vessel at the same time, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com