Crucible and preparation device and method for special dispersion glass

A crucible, special technology, applied in the field of crucible and special dispersion glass preparation equipment, to achieve the effects of controlling volatilization, isolating outside air, high optical uniformity and batch consistency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

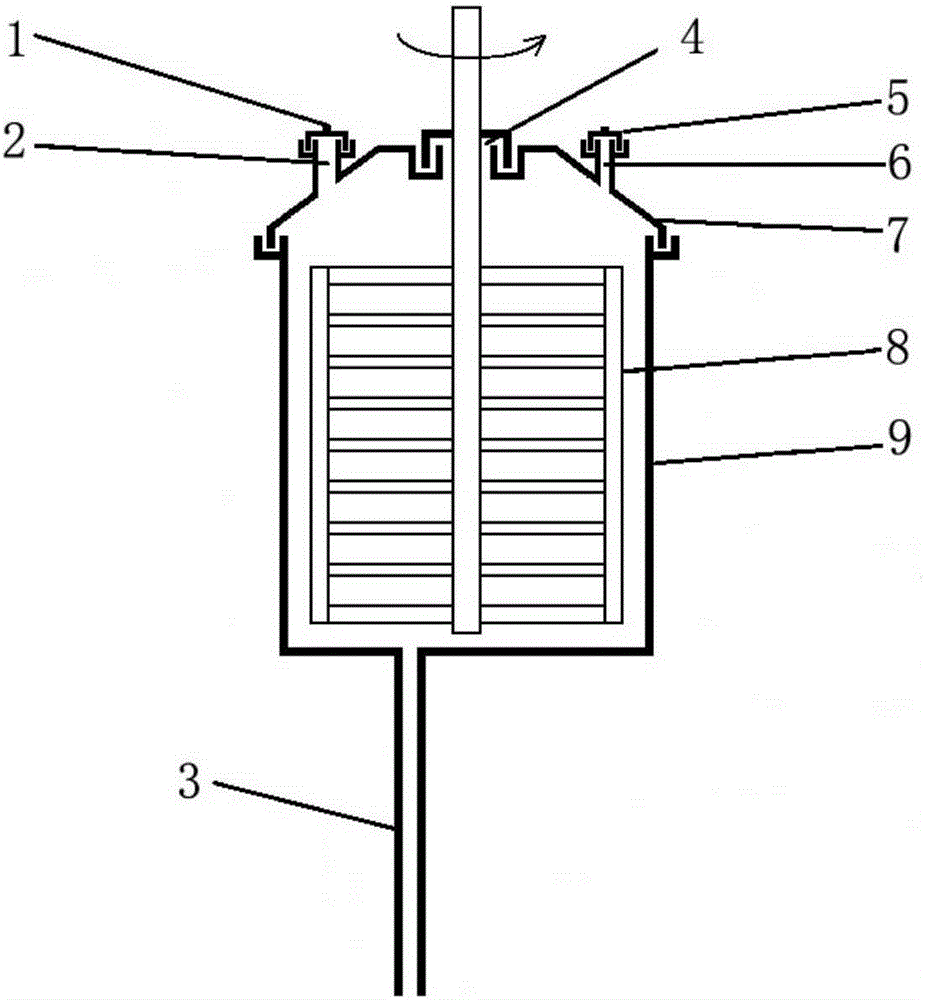

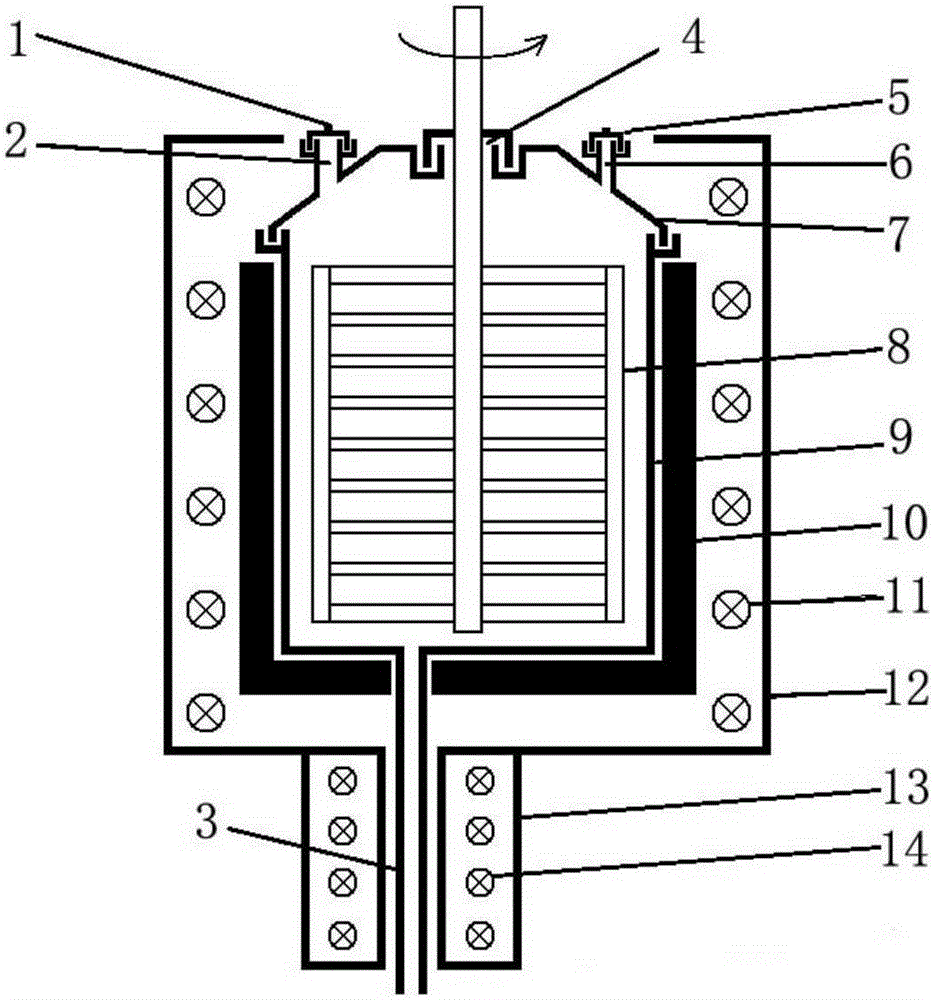

[0046] The preparation method of the special dispersion glass provided in the embodiment of the present invention is prepared by using the above-mentioned preparation device. The outside of the melting furnace is made of heat-resistant stainless steel plate, the inside is made of mullite refractory material, and the lower part is a steel structure support; the melting furnace is provided with a crucible cover 10, through which the crucible is heated, and the material of the crucible cover is clay or quartz ceramics The melting furnace is provided with a first heating element 11, which is a silicon molybdenum rod, which can make the temperature in the melting furnace reach up to 1650 °C; the auxiliary furnace is provided with a second heating element 14, which is It is a silicon carbide rod, which can make the temperature in the auxiliary furnace reach up to 1400°C; crucible cover, material guide pipe, leakage pipe, first plug, second plug, first to fourth annular grooves, first...

Embodiment 1

[0050] The steps of preparing special dispersion glass in this embodiment are as follows:

[0051] (1) Accurately weigh the following glass raw materials: quartz sand 1.22kg, boric acid 6.39kg, tantalum pentoxide 2.64kg, zirconium dioxide 1.80kg, soda ash 0.62kg, potassium carbonate 1.76kg, zinc oxide 0.24Kg, hafnium oxide 0.84kg and antimony trioxide 0.12kg, after mixing evenly, place it in a traditional melting furnace and melt it into molten glass under normal pressure;

[0052] (2) Put the crucible in the melting furnace, open the feeding port and exhaust port on the crucible cover, and then heat the melting furnace and auxiliary furnace to keep the temperature in the crucible at 1400°C and the temperature in the leakage pipe at 1300°C ; The gap between the agitator and the stirring hole is liquid-sealed by the liquid seal structure between the first seal on the stirrer and the crucible lid, and the liquid seal liquid used is the glass liquid obtained by the above-mentione...

Embodiment 2

[0056] The steps of preparing special dispersion glass in this embodiment are as follows:

[0057] (1) Accurately weigh the following glass raw materials: quartz sand 1.71kg, boric acid 4.26kg, tantalum pentoxide 3.60kg, zirconium dioxide 1.44kg, potassium carbonate 2.29kg, lithium carbonate 0.3kg, zinc oxide 0.12kg, calcium carbonate 0.22 kg, 0.31kg of barium carbonate, 0.6kg of hafnium oxide and 0.12kg of antimony trioxide, after mixing evenly, place it in a traditional melting furnace and melt it into molten glass under normal pressure;

[0058] (2) Put the crucible in the melting furnace, open the feeding port and exhaust port on the crucible cover, and then heat the melting furnace and auxiliary furnace to keep the temperature in the crucible at 1350°C and the temperature in the leakage pipe at 1250°C ; The gap between the agitator and the stirring hole is liquid-sealed by the liquid seal structure between the first seal on the stirrer and the crucible lid, and the liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com