Adsorbents for mud in concrete aggregates

An adsorbent and concrete technology, applied in the field of concrete, can solve the problems of reducing concrete performance, improving concrete production and use cost, and achieving the effects of reducing adsorption, reducing adsorption effect, and reducing adsorption effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

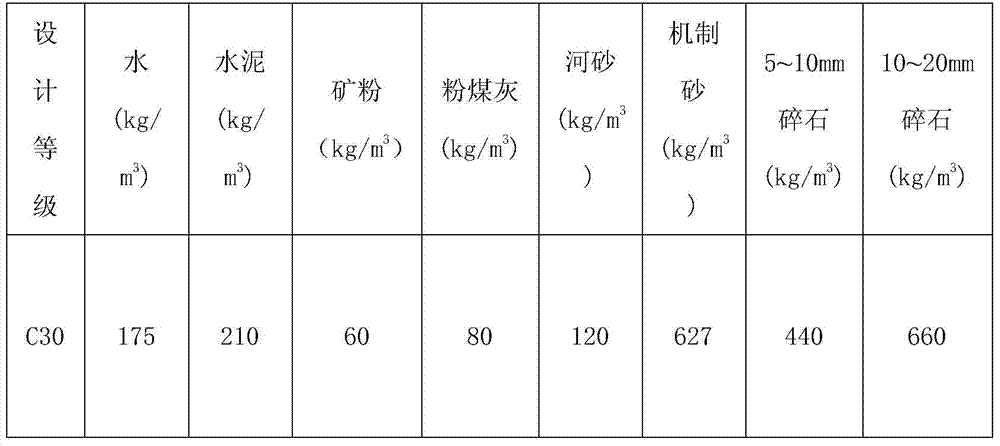

Method used

Image

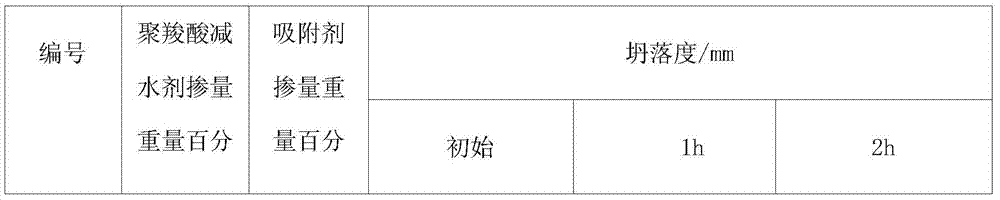

Examples

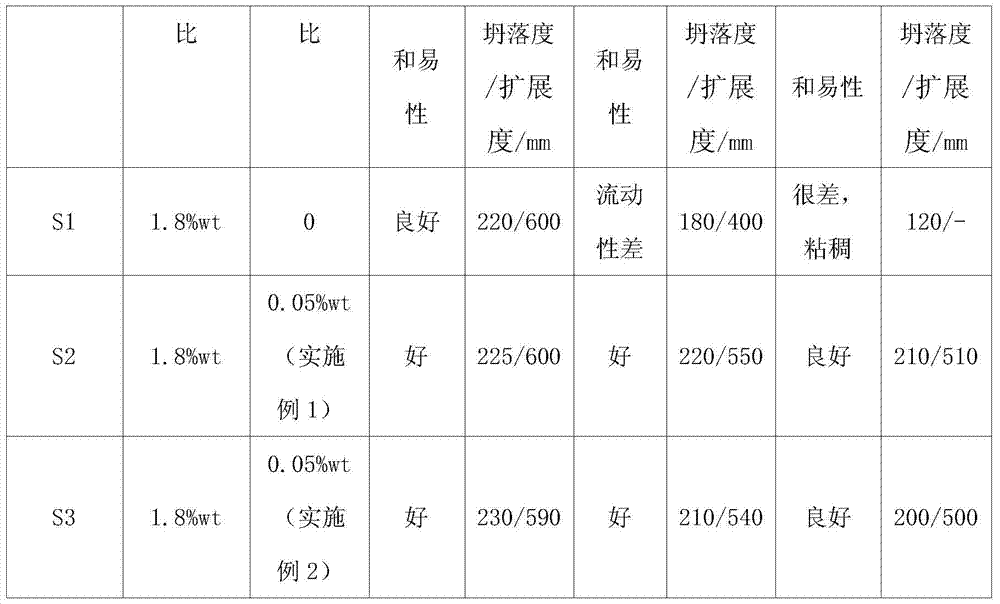

Embodiment 1

[0016] Get each component by the following weight percentages,

[0017] Prenol polyoxyethylene ether: 15%; polyethylene glycol (molecular weight: 2000): 10%; sodium hexametaphosphate: 2%; sodium silicate 3%; water: 70%. The above-mentioned components are mixed and dissolved to form an aqueous solution with a concentration of 30% wt to obtain the adsorbent.

Embodiment 2

[0019] Get each component by the following weight percentages,

[0020] Isobutenol polyoxyethylene ether: 20%; polyethylene glycol (molecular weight: 4000): 5%; sodium polyphosphate: 3%; potassium silicate 2%; water: 70%. The above-mentioned components are mixed and dissolved to form an aqueous solution with a concentration of 30% wt to obtain the adsorbent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com