Colored hollow polymer emulsion and preparation method thereof

A technology of emulsion and emulsion polymerization, applied in application, coating, ink, etc., can solve problems such as uneven color, poor color fastness to light, and poor compatibility between dyes and polymer matrix

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

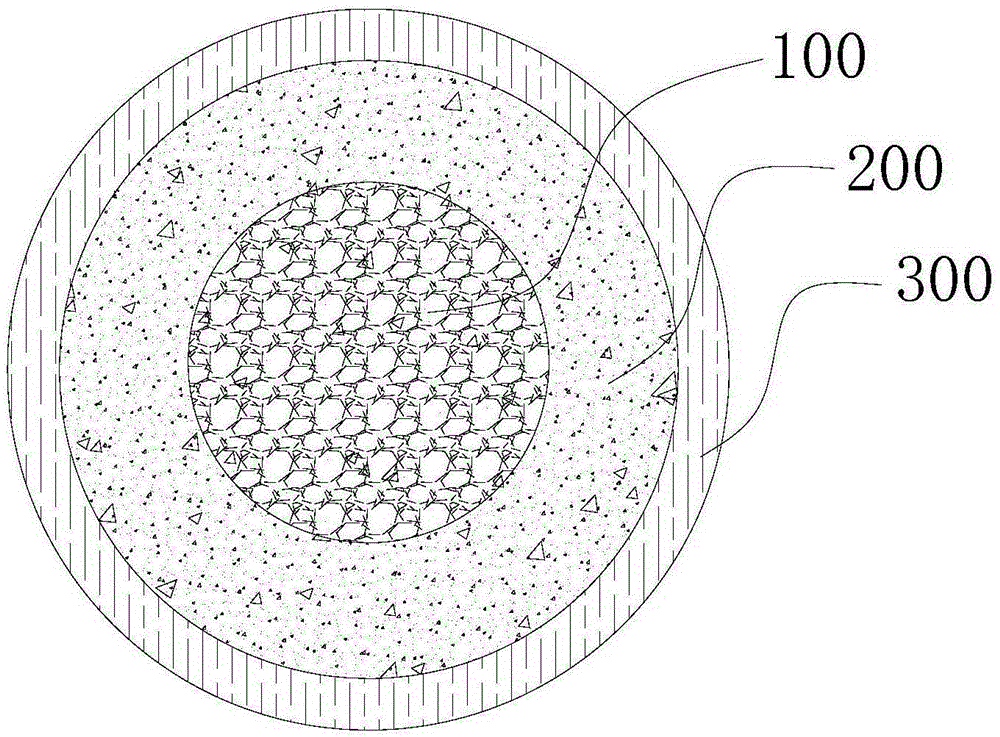

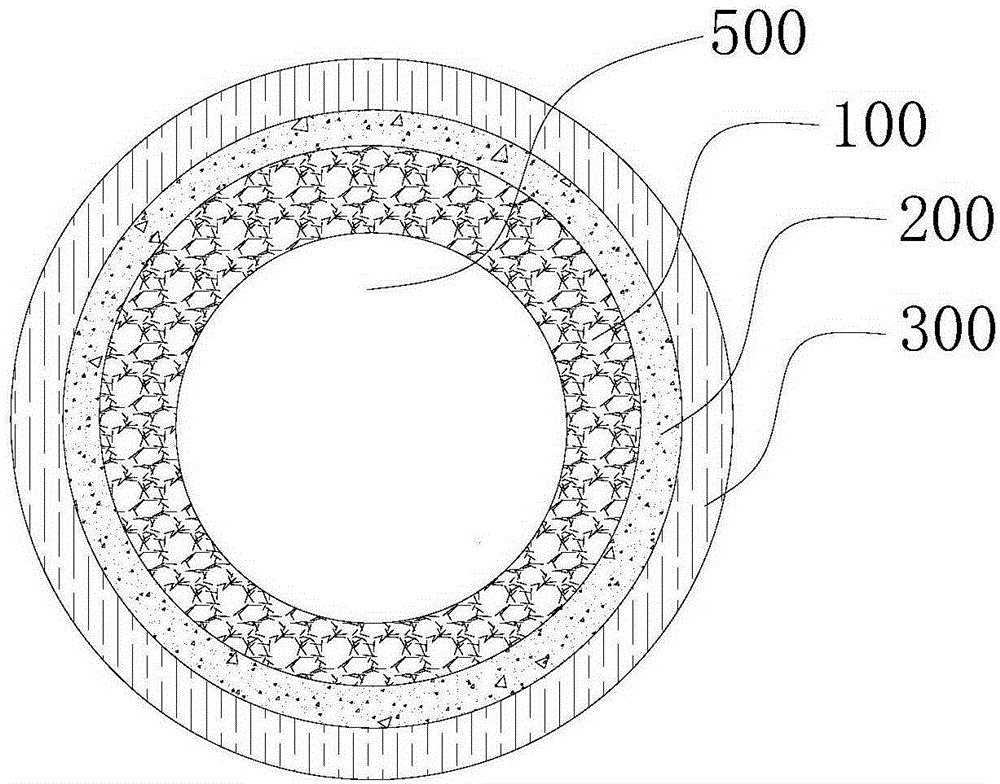

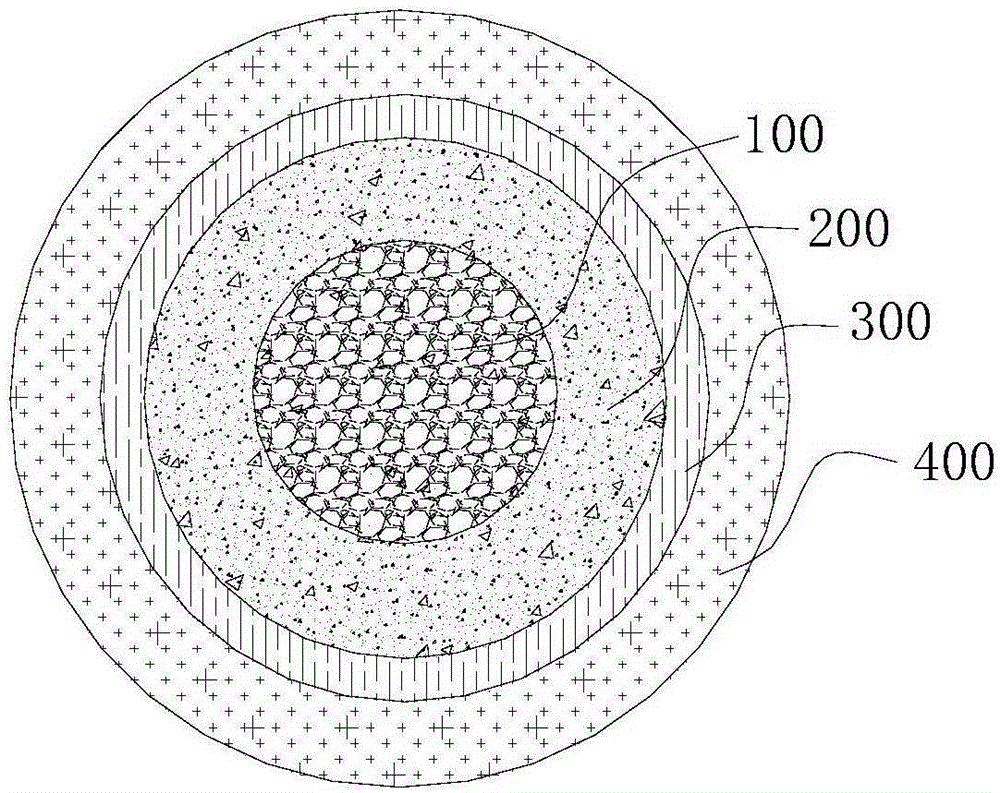

Image

Examples

Embodiment 1

[0104] Example 1 - Emulsion Containing Red Dye

[0105] (1) Formation of nuclei: Add 60 g of deionized water and 0.05 g of sodium lauryl sulfate into a 250 ml four-necked flask, stir and mix, blow nitrogen gas, and heat to 65°C. 2 grams of red polymerizable dye 1-(6-acrylamido) hexylaminoanthraquinone, 10 grams of methacrylic acid, 40 grams of methyl methacrylate, 40 grams of deionized water, 0.25 grams of sodium lauryl sulfate Mix well with 0.5 g of nonylphenol polyoxyethylene ether (OP-10) to obtain a pre-emulsion; dissolve 0.25 g of ammonium persulfate in 30 g of deionized water to prepare an initiator solution. Take 10 grams of the above-mentioned monomer pre-emulsion and 12 grams of the initiator solution, and add them together to the above-mentioned four-necked bottle, and heat and stir for 2 hours to obtain a seed emulsion. Add the remaining pre-emulsion and initiator solution dropwise into the above-mentioned four-necked bottle for 2 hours. After the dropwise addition...

Embodiment 2

[0109] Example 2 - Emulsion Containing Red Dye

[0110] (1) Formation of nuclei: Add 60 g of deionized water and 0.025 g of sodium lauryl sulfate into a 250 ml four-necked flask, stir and mix, replace with nitrogen, and heat to 75°C. 30 grams of methacrylic acid, 19 grams of methyl methacrylate, 1 gram of ethylene glycol bis(methacrylate), 40 grams of deionized water, 0.75 grams of sodium lauryl sulfate and 0.75 grams of nonylphenol polyoxyethylene The ether (OP-10) was fully mixed to obtain a monomer pre-emulsion; 0.6 g of ammonium persulfate was dissolved in 30 g of deionized water to prepare an initiator solution. Take 2.5 grams of the above-mentioned monomer pre-emulsion and 3 grams of the initiator solution, and add them together to the above-mentioned four-neck bottle, heat and stir for 20 minutes to obtain a seed emulsion. Add the remaining monomer pre-emulsion and initiator solution dropwise into the above-mentioned four-necked bottle for 4.5 hours. After the dropwise...

Embodiment 3

[0114] Example 3 - Emulsion Containing Red Dye

[0115](1) Formation of nuclei: Add 60 g of deionized water and 0.025 g of sodium lauryl sulfate into a 250 ml four-neck flask, stir and mix, replace with nitrogen, and heat to 85°C. 1 gram of red polymerizable dye 3-(4-(4'-N, N-dimethylaminophenyl azo) phthalimide) propyl-2-methacrylate, 20.25 gram methacrylic acid, 29.5 gram methyl methacrylate, 0.25 gram bis(methacrylate) glycol ester, 40 gram deionized water, 0.25 gram sodium lauryl sulfate and 0.75 gram nonylphenol ethoxylate ( OP-10) was fully mixed to obtain a monomer pre-emulsion; 0.5 grams of ammonium persulfate was dissolved in 30 grams of deionized water to prepare an initiator solution. Take 5 grams of the above-mentioned monomer pre-emulsion and 6 grams of the initiator solution, add them together to the above-mentioned four-necked bottle, keep warm and stir for 2 hours, and obtain the seed emulsion. The remaining monomer pre-emulsion and initiator solution were ad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com