Antiskid anti-abrasion EVA shoe sole material and preparation method thereof

A technology of sole material and wear-resistant agent, applied in the field of organic polymer materials, can solve the problems of insufficient friction between the sole and the road surface, heavy wearing feeling, short service life, etc., and achieves low hardness, good slip resistance and service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

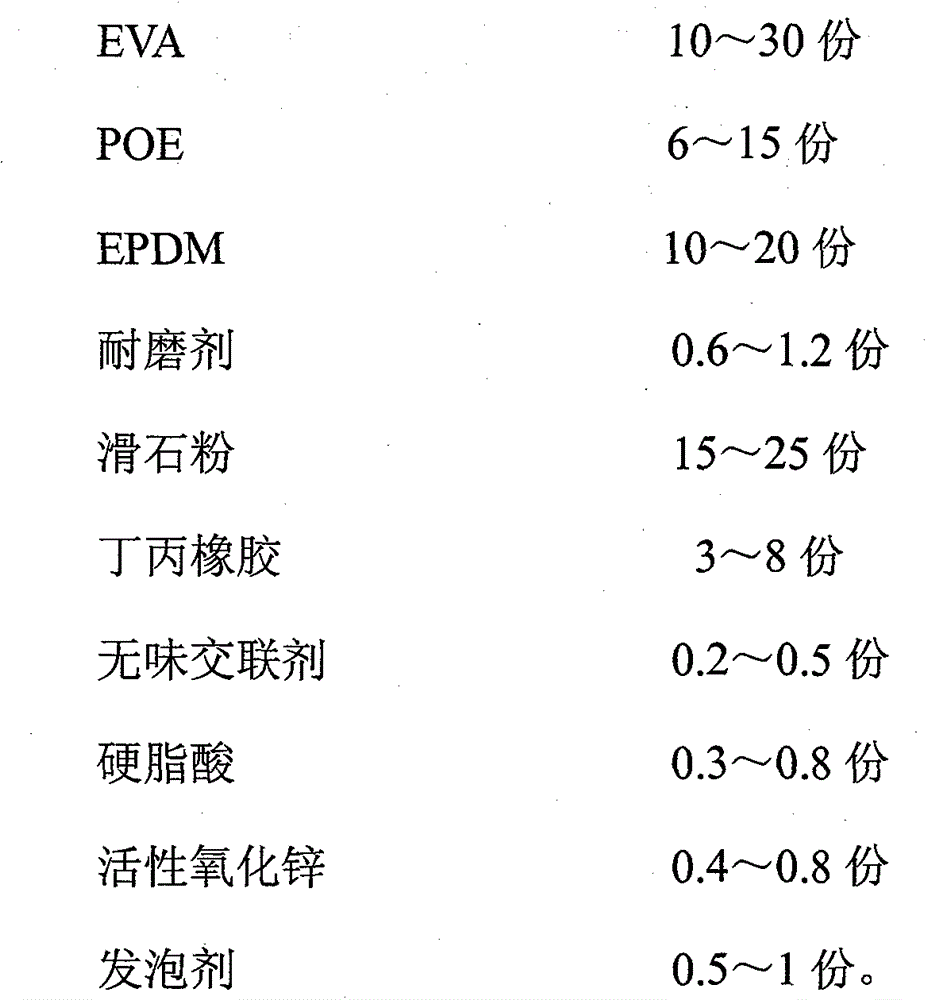

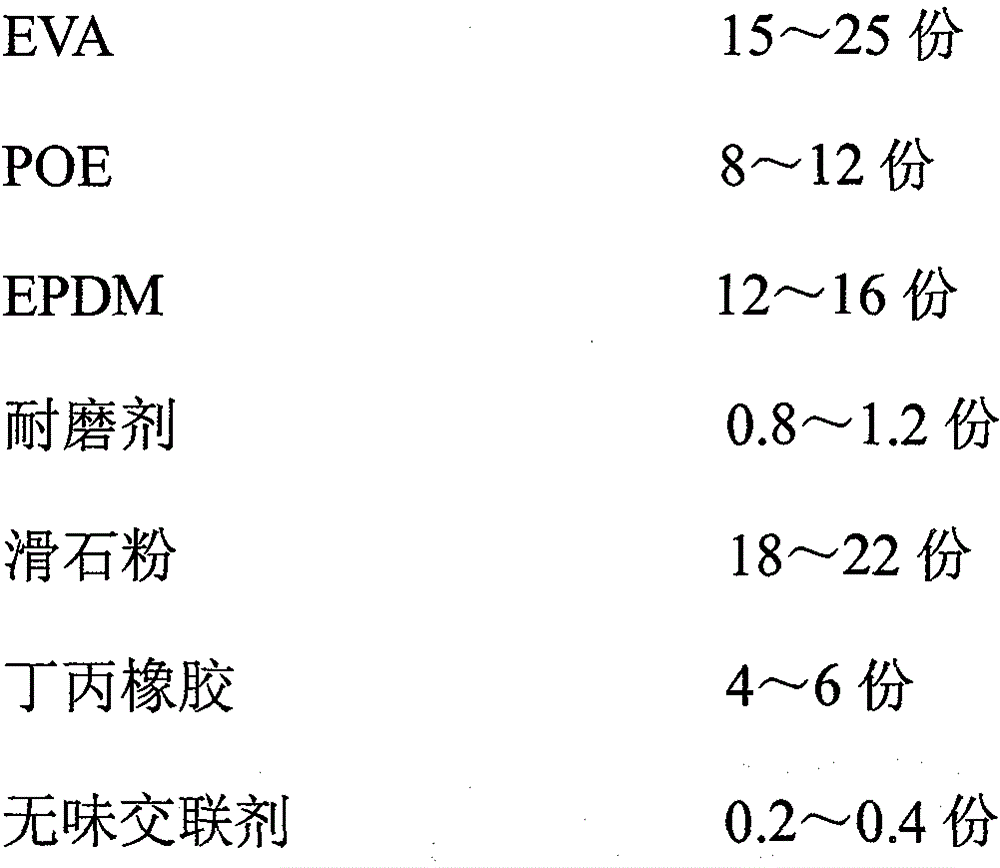

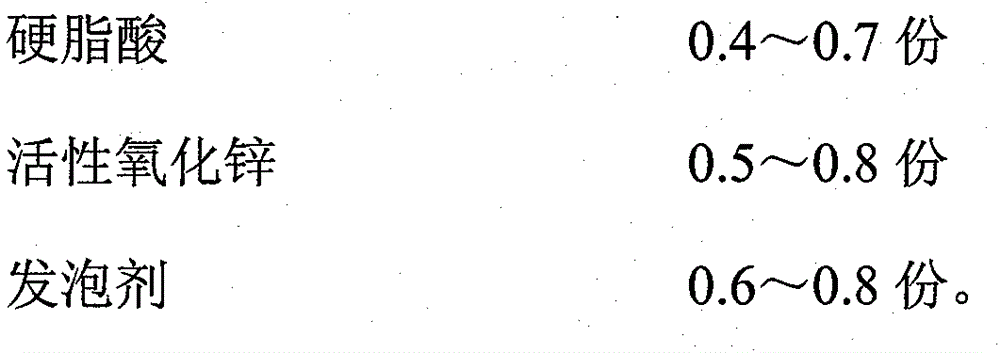

Method used

Image

Examples

Embodiment 1

[0018] A kind of antiskid wear-resisting EVA sole material, described EVA sole material is mainly made of EVA, POE, EPDM, wear-resisting agent, talc powder, butyl rubber, odorless crosslinking agent, stearic acid, active zinc oxide, foaming agent It is formed by kneading and foaming. The content of each component, by weight, is: 10 parts of EVA, 6 parts of POE, 10 parts of EPDM, 0.8 parts of anti-wear agent, 15 parts of talcum powder, 3 parts of propylene rubber, odorless 0.2 parts of crosslinking agent, 0.3 parts of stearic acid, 0.4 parts of activated zinc oxide, and 0.5 parts of foaming agent.

[0019] The preparation method of the above-mentioned anti-slip and wear-resistant EVA sole material mainly comprises the following steps:

[0020] (1) Internal mixing: first put the six materials of EVA, POE, EPDM, wear-resistant agent, butyl propylene rubber, and talcum powder into the internal mixer for internal mixing; when the temperature in the internal mixer increases When th...

Embodiment 2

[0024] A kind of antiskid wear-resisting EVA sole material, described EVA sole material is mainly made of EVA, POE, EPDM, wear-resisting agent, talc powder, butyl rubber, odorless crosslinking agent, stearic acid, active zinc oxide, foaming agent It is formed by kneading and foaming. The content of each component, by weight, is: 20 parts of EVA, 10 parts of POE, 15 parts of EPDM, 1 part of anti-wear agent, 20 parts of talcum powder, 5 parts of butyl propylene rubber, odorless 0.35 parts of crosslinking agent, 0.5 parts of stearic acid, 0.6 parts of active zinc oxide, and 0.7 parts of foaming agent.

[0025] The preparation method of the above-mentioned anti-slip and wear-resistant EVA sole material is the same as in Example 1.

Embodiment 3

[0027] A kind of antiskid wear-resisting EVA sole material, described EVA sole material is mainly made of EVA, POE, EPDM, wear-resisting agent, talc powder, butyl rubber, odorless crosslinking agent, stearic acid, active zinc oxide, foaming agent It is formed by kneading and foaming. The content of each component, by weight, is: 30 parts of EVA, 15 parts of POE, 20 parts of EPDM, 1.5 parts of anti-wear agent, 25 parts of talcum powder, 8 parts of propylene rubber, odorless 0.5 part of crosslinking agent, 0.8 part of stearic acid, 0.8 part of active zinc oxide, and 1 part of foaming agent.

[0028] The preparation method of the above-mentioned anti-slip and wear-resistant EVA sole material is the same as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com